Kraft paper offers superior strength and durability due to its high-quality wood fibers and minimal chemical processing, making it ideal for packaging heavy items. Sulphite paper, produced through a chemical pulping process, features a smoother texture and brightness suitable for printing and writing applications. Both papers serve distinct purposes, with kraft paper favored for toughness and sulphite paper for fine, printable surfaces.

Table of Comparison

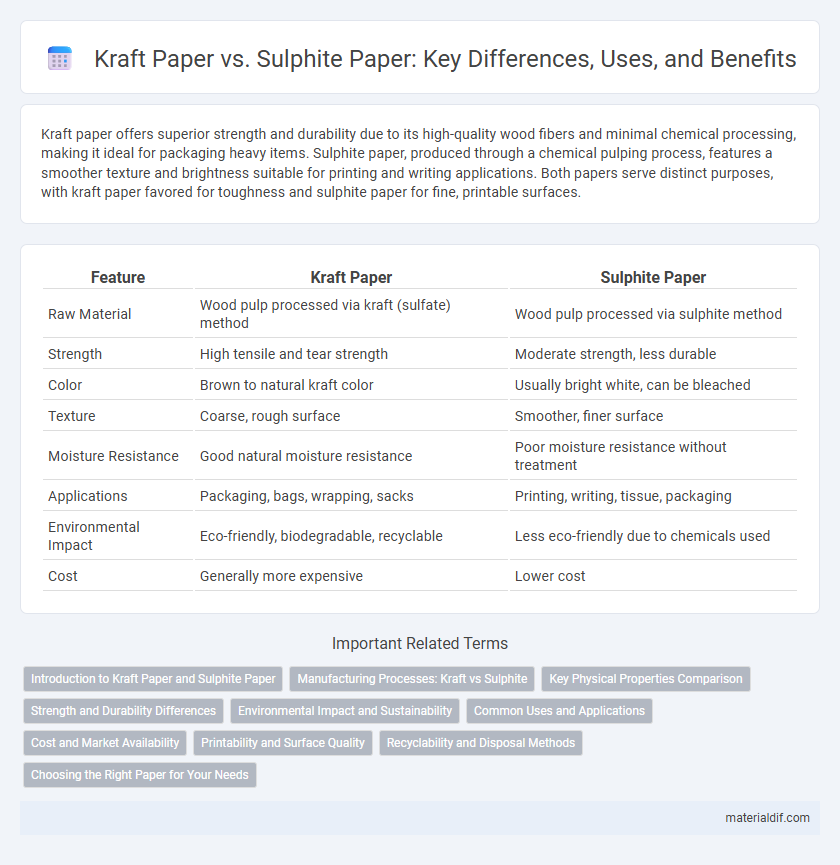

| Feature | Kraft Paper | Sulphite Paper |

|---|---|---|

| Raw Material | Wood pulp processed via kraft (sulfate) method | Wood pulp processed via sulphite method |

| Strength | High tensile and tear strength | Moderate strength, less durable |

| Color | Brown to natural kraft color | Usually bright white, can be bleached |

| Texture | Coarse, rough surface | Smoother, finer surface |

| Moisture Resistance | Good natural moisture resistance | Poor moisture resistance without treatment |

| Applications | Packaging, bags, wrapping, sacks | Printing, writing, tissue, packaging |

| Environmental Impact | Eco-friendly, biodegradable, recyclable | Less eco-friendly due to chemicals used |

| Cost | Generally more expensive | Lower cost |

Introduction to Kraft Paper and Sulphite Paper

Kraft paper is produced using the kraft process, which involves chemically treating wood chips to remove lignin, resulting in a strong and durable paper ideal for packaging and industrial applications. Sulphite paper is made through the sulphite process, where wood pulp is treated with sulphurous acid, producing a softer, smoother paper commonly used for writing and printing. Both papers differ primarily in their manufacturing methods, strength, and typical uses, with kraft paper emphasizing durability and sulphite paper focusing on quality surface texture.

Manufacturing Processes: Kraft vs Sulphite

Kraft paper is produced using the kraft process, which involves cooking wood chips in a mixture of sodium hydroxide and sodium sulfide, resulting in stronger fibers and higher durability. Sulphite paper is manufactured through the sulphite process, where wood chips are treated with sulfurous acid and bisulfite ions to break down lignin, producing softer and more refined pulp. The kraft process yields a more resilient paper suitable for packaging, whereas the sulphite method produces paper favored for printing and fine writing due to its smooth texture.

Key Physical Properties Comparison

Kraft paper exhibits higher tensile strength and superior tear resistance compared to sulphite paper, making it ideal for heavy-duty packaging and industrial uses. Sulphite paper offers smoother surface texture and better brightness, which enhances printability for graphic applications. Moisture resistance in kraft paper is significantly better due to its lignin content, while sulphite paper generally absorbs more water, leading to reduced durability in humid conditions.

Strength and Durability Differences

Kraft paper is produced using the kraft process, which retains more lignin and results in fibers with higher tensile strength and superior durability compared to sulphite paper. Sulphite paper, made through the sulphite pulping process, typically has lower brightness and weaker fiber bonding, leading to reduced resistance to tearing and wear. The robust fiber structure of kraft paper makes it ideal for heavy-duty packaging and industrial applications requiring enhanced strength and longevity.

Environmental Impact and Sustainability

Kraft paper, produced through a strong chemical pulping process, is highly valued for its durability and recyclability, contributing to lower environmental impact by promoting reuse and reducing landfill waste. In contrast, sulphite paper involves a more chemically intensive process, often resulting in weaker fibers and higher energy consumption, which can lead to increased environmental burden. Sustainable sourcing of raw materials and certified fiber content, such as FSC-certified kraft paper, enhances eco-friendliness by supporting responsible forestry and reducing deforestation risks.

Common Uses and Applications

Kraft paper is widely used for packaging, wrapping, and industrial bags due to its high strength and durability, making it ideal for heavy-duty applications such as grocery bags and shipping materials. Sulphite paper, favored for its smooth surface and superior printability, is commonly employed in publishing, art paper, and office stationery production. Both papers serve distinct roles based on their fiber pulping processes, with kraft paper excelling in toughness and sulphite paper in finish quality.

Cost and Market Availability

Kraft paper typically offers a higher cost-effectiveness due to its strong fibers and efficient manufacturing process, making it widely available in packaging and industrial markets. Sulphite paper generally has a higher production cost because of the chemical pulping process, limiting its availability primarily to specialty applications like printing and fine paper markets. Market availability of kraft paper surpasses sulphite paper, driven by its demand in bulk packaging and eco-friendly products sectors.

Printability and Surface Quality

Kraft paper exhibits higher printability due to its coarse texture and strong fiber composition, allowing better ink absorption and durability for packaging applications. Sulphite paper offers superior surface quality with its smooth, fine fibers, resulting in sharper image reproduction and vibrant color output ideal for high-quality printing needs. Manufacturers often choose kraft paper for strength and rough designs, while sulphite paper suits detailed, visually appealing print products.

Recyclability and Disposal Methods

Kraft paper features high recyclability due to its strong fibers and minimal chemical treatment, making it ideal for eco-friendly packaging and easy reintegration into the recycling system. Sulphite paper, while also recyclable, undergoes chemical pulping that can affect fiber strength and limits the number of recycling cycles compared to kraft. Both papers are biodegradable and can be composted, but kraft paper's natural brown color often excludes the need for bleaching agents, reducing environmental impact in disposal.

Choosing the Right Paper for Your Needs

Kraft paper offers superior strength and durability due to its chemical processing, making it ideal for packaging heavy or abrasive items, while sulphite paper features a smoother texture and higher brightness suited for printing and writing applications. Selecting the right paper depends on balancing factors like tensile strength, print quality, and environmental considerations such as recyclability and biodegradability. Understanding these characteristics ensures optimal performance and cost-efficiency tailored to specific industrial or creative needs.

Kraft Paper vs Sulphite Paper Infographic

materialdif.com

materialdif.com