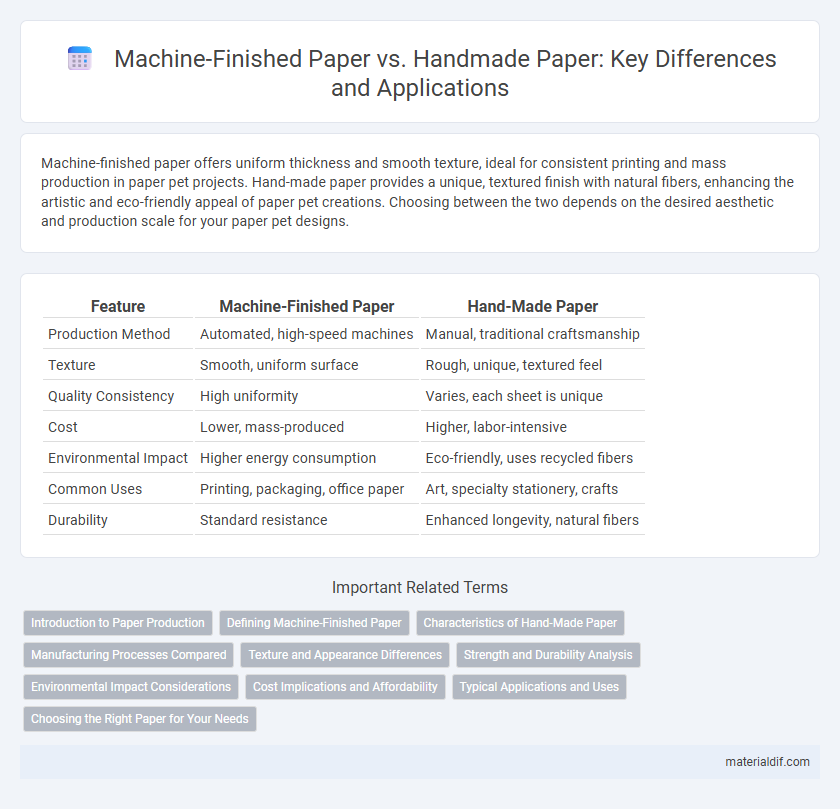

Machine-finished paper offers uniform thickness and smooth texture, ideal for consistent printing and mass production in paper pet projects. Hand-made paper provides a unique, textured finish with natural fibers, enhancing the artistic and eco-friendly appeal of paper pet creations. Choosing between the two depends on the desired aesthetic and production scale for your paper pet designs.

Table of Comparison

| Feature | Machine-Finished Paper | Hand-Made Paper |

|---|---|---|

| Production Method | Automated, high-speed machines | Manual, traditional craftsmanship |

| Texture | Smooth, uniform surface | Rough, unique, textured feel |

| Quality Consistency | High uniformity | Varies, each sheet is unique |

| Cost | Lower, mass-produced | Higher, labor-intensive |

| Environmental Impact | Higher energy consumption | Eco-friendly, uses recycled fibers |

| Common Uses | Printing, packaging, office paper | Art, specialty stationery, crafts |

| Durability | Standard resistance | Enhanced longevity, natural fibers |

Introduction to Paper Production

Machine-finished paper is produced using automated processes that ensure uniform thickness, smooth surface, and consistent quality by pressing and drying paper webs through rollers. Hand-made paper involves traditional techniques where fibers are manually suspended in water, lifted on a screen, and pressed to form sheets, resulting in unique textures and irregularities valued for artisanal and archival purposes. Both methods start with raw materials such as wood pulp, cotton, or recycled fibers, but differ significantly in scale, efficiency, and tactile characteristics.

Defining Machine-Finished Paper

Machine-finished paper refers to paper that undergoes surface treatment using machines to improve smoothness, gloss, and printability, typically produced in large quantities via automated processes. This type of paper is characterized by consistent texture and uniform thickness, making it ideal for commercial printing and publishing. Machine finishing involves calendering and coating techniques that enhance durability and visual appeal compared to traditional hand-made paper.

Characteristics of Hand-Made Paper

Hand-made paper features a unique texture and irregular edges, resulting from the manual sheet-forming process that preserves natural fibers. It typically exhibits higher durability, superior absorbency, and an organic appearance compared to machine-finished paper. Artisans often use recycled or specialty fibers in hand-made paper, contributing to its distinct aesthetic and environmentally friendly properties.

Manufacturing Processes Compared

Machine-finished paper is produced using automated, high-speed machines that apply consistent pressure and temperature to achieve uniform thickness and smoothness, optimizing production efficiency and scalability. In contrast, hand-made paper involves manual techniques where pulp is delicately spread on screens, pressed, and dried, allowing for unique textures and higher artistic value. The mechanical process emphasizes precision and volume, whereas hand-made paper prioritizes craftsmanship and individual character in each sheet.

Texture and Appearance Differences

Machine-finished paper exhibits a smooth, uniform texture due to precise rollers and surface treatments, resulting in consistent gloss and even coloration ideal for mass printing. In contrast, hand-made paper features a tactile, irregular surface with natural fiber variations and deckled edges that create a distinctive artisanal appearance often sought after for fine art and specialty stationery. The visual and textural differences between these papers influence their suitability, with machine-finished paper excelling in uniformity and hand-made paper valued for unique aesthetic character.

Strength and Durability Analysis

Machine-finished paper exhibits consistent strength and durability due to its uniform fiber distribution and controlled manufacturing process, making it ideal for high-volume printing and packaging applications. Hand-made paper, while often less uniform, can demonstrate superior durability through the use of long, natural fibers and traditional crafting techniques that enhance tensile strength and resistance to tearing. The choice between machine-finished and hand-made paper ultimately depends on the specific strength and durability requirements of the intended use.

Environmental Impact Considerations

Machine-finished paper typically involves high energy consumption and chemical treatments that contribute to environmental pollution, whereas hand-made paper uses fewer chemicals and less energy, resulting in a smaller carbon footprint. The production of hand-made paper often employs recycled fibers and natural processes, reducing waste and promoting sustainability. Considering lifecycle assessments, hand-made paper generally supports eco-friendly practices by minimizing resource depletion and lowering greenhouse gas emissions compared to industrial machine-finished paper production.

Cost Implications and Affordability

Machine-finished paper offers significant cost advantages over hand-made paper, benefiting from automation and high-volume production that reduce labor expenses and material waste. Hand-made paper, requiring skilled craftsmanship and longer processing times, incurs higher production costs, making it less affordable for large-scale or budget-conscious projects. The affordability of machine-finished paper makes it the preferred choice for everyday printing and commercial use, while hand-made paper remains a premium option for artisanal and specialized applications.

Typical Applications and Uses

Machine-finished paper is widely used in commercial printing, packaging, and office supplies due to its consistent texture and cost-effectiveness, making it ideal for high-volume production such as newspapers, magazines, and brochures. Hand-made paper is favored in fine art, luxury stationery, and specialty crafts because of its unique texture, durability, and aesthetic appeal, often utilized in certificates, invitations, and artisanal bookbinding. Both types serve distinct roles where machine-finished paper addresses mass-market needs and hand-made paper supports bespoke, high-quality projects.

Choosing the Right Paper for Your Needs

Machine-finished paper offers consistent texture and durability ideal for high-volume printing and commercial use, while hand-made paper provides unique texture and aesthetic appeal suited for artistic projects and special documents. Selecting the right paper depends on factors such as desired finish, budget constraints, and the purpose of the printed material. For everyday use, machine-finished paper ensures efficiency and uniformity, whereas hand-made paper enhances tactile experience and visual uniqueness.

Machine-Finished Paper vs Hand-Made Paper Infographic

materialdif.com

materialdif.com