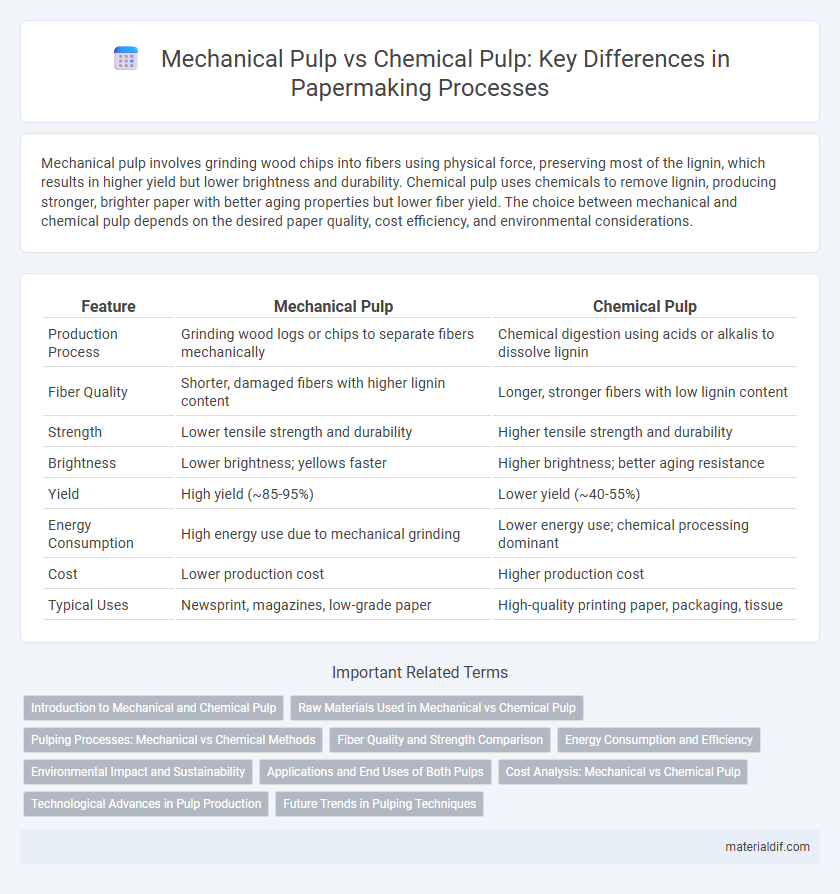

Mechanical pulp involves grinding wood chips into fibers using physical force, preserving most of the lignin, which results in higher yield but lower brightness and durability. Chemical pulp uses chemicals to remove lignin, producing stronger, brighter paper with better aging properties but lower fiber yield. The choice between mechanical and chemical pulp depends on the desired paper quality, cost efficiency, and environmental considerations.

Table of Comparison

| Feature | Mechanical Pulp | Chemical Pulp |

|---|---|---|

| Production Process | Grinding wood logs or chips to separate fibers mechanically | Chemical digestion using acids or alkalis to dissolve lignin |

| Fiber Quality | Shorter, damaged fibers with higher lignin content | Longer, stronger fibers with low lignin content |

| Strength | Lower tensile strength and durability | Higher tensile strength and durability |

| Brightness | Lower brightness; yellows faster | Higher brightness; better aging resistance |

| Yield | High yield (~85-95%) | Lower yield (~40-55%) |

| Energy Consumption | High energy use due to mechanical grinding | Lower energy use; chemical processing dominant |

| Cost | Lower production cost | Higher production cost |

| Typical Uses | Newsprint, magazines, low-grade paper | High-quality printing paper, packaging, tissue |

Introduction to Mechanical and Chemical Pulp

Mechanical pulp is produced by physically grinding wood chips into fibers, retaining most of the lignin for higher yield but resulting in lower strength and brightness. Chemical pulp involves treating wood chips with chemicals such as sulfates or sulfites to dissolve lignin, producing stronger, brighter fibers suitable for high-quality paper. The choice between mechanical and chemical pulp impacts paper properties, cost, and production efficiency, with mechanical pulp favored for newsprint and chemical pulp preferred for printing and writing papers.

Raw Materials Used in Mechanical vs Chemical Pulp

Mechanical pulp primarily uses wood chips or logs processed through grinding or refining, preserving most of the lignin and cellulose in the raw material. Chemical pulp relies on wood chips treated with chemicals like sodium hydroxide and sodium sulfide to dissolve lignin, yielding higher-purity cellulose fibers. The choice of raw material preparation significantly impacts pulp yield, fiber strength, and paper quality.

Pulping Processes: Mechanical vs Chemical Methods

Mechanical pulping uses physical grinding to separate fibers, preserving most of the lignin and resulting in higher yield but lower brightness and strength. Chemical pulping employs chemicals such as sodium hydroxide and sodium sulfide to dissolve lignin, producing stronger, brighter pulp with lower yield due to fiber degradation. The choice between mechanical and chemical pulping methods impacts paper quality, production costs, and environmental considerations, with chemical pulping favored for high-strength paper and mechanical pulping for cost-effective, high-volume newsprint.

Fiber Quality and Strength Comparison

Mechanical pulp retains most of the wood fibers, resulting in higher yield but lower fiber strength due to fiber damage and shorter fiber length compared to chemical pulp. Chemical pulp undergoes lignin removal through chemical processes, producing longer, stronger fibers that enhance paper durability and tensile strength. Consequently, paper made from chemical pulp exhibits superior fiber quality and structural integrity, making it ideal for high-strength applications.

Energy Consumption and Efficiency

Mechanical pulp production consumes significantly more energy, averaging around 2,500 kWh per ton, compared to chemical pulp, which requires approximately 1,000 kWh per ton. Despite higher energy use, mechanical pulping offers greater yield efficiency, retaining up to 95% of the raw wood, whereas chemical pulping yields about 50% due to lignin removal. This trade-off between energy intensity and raw material efficiency critically impacts cost and environmental considerations in industrial paper manufacturing.

Environmental Impact and Sustainability

Mechanical pulp production consumes less energy than chemical pulping but results in lower paper strength and higher lignin content, affecting recyclability. Chemical pulping, especially kraft pulping, requires more energy and chemicals but produces stronger, more durable paper with better recyclability and less environmental pollution when combined with effective waste treatment. Sustainable practices in both methods include reducing water use, recycling black liquor in chemical pulping, and optimizing energy efficiency to minimize ecological footprints.

Applications and End Uses of Both Pulps

Mechanical pulp is predominantly used in the production of newsprint, catalogs, and paperboard due to its high yield and retained lignin, which imparts bulk and opacity. Chemical pulp, characterized by higher strength and brightness, finds extensive applications in printing papers, fine writing papers, and packaging materials where durability and print quality are critical. Both pulps serve complementary roles in the paper industry, with mechanical pulp favored for economy and opacity, while chemical pulp is chosen for quality and longevity.

Cost Analysis: Mechanical vs Chemical Pulp

Mechanical pulp production incurs lower energy costs due to simpler processing but results in higher expenses for bleaching and refining to improve paper brightness and strength. Chemical pulp involves higher initial energy and chemical costs, yet offers superior fiber quality that reduces overall production expenses by minimizing paper defects and enhancing durability. Evaluating cost efficiency requires balancing the higher chemical input of chemical pulping against the increased mechanical and post-processing costs of mechanical pulping.

Technological Advances in Pulp Production

Mechanical pulp production has evolved with high-consistency refining and energy-efficient grinders that enhance fiber separation while preserving wood structure. Chemical pulp processes benefit from innovations in kraft and sulfite cooking, including continuous digesters and improved chemical recovery systems that increase yield and reduce environmental impact. Advances in enzymatic treatments and hybrid pulping technologies are bridging the gap between mechanical and chemical methods, optimizing both fiber quality and production sustainability.

Future Trends in Pulping Techniques

Future trends in pulping techniques emphasize sustainable innovations such as enzymatic hydrolysis and biopulping, which reduce energy consumption and chemical usage compared to traditional mechanical and chemical pulping methods. Advances in pretreatment technologies aim to enhance fiber quality and yield, promoting the integration of circular economy principles in pulp production. Industry research increasingly targets hybrid processes that combine mechanical and chemical treatments to optimize environmental impact and improve paper strength and brightness.

Mechanical Pulp vs Chemical Pulp Infographic

materialdif.com

materialdif.com