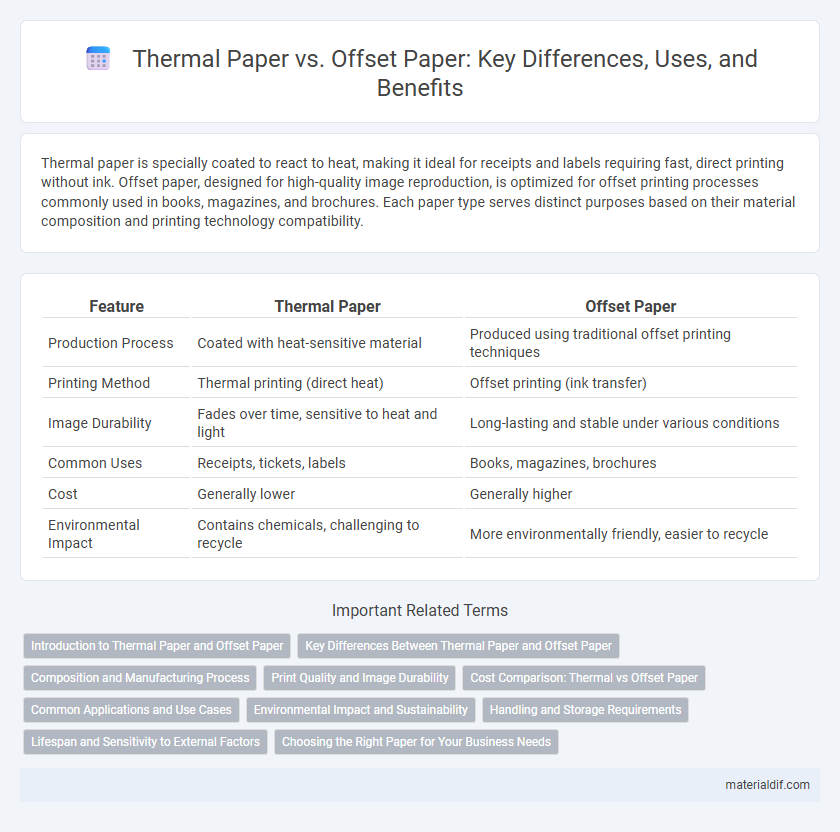

Thermal paper is specially coated to react to heat, making it ideal for receipts and labels requiring fast, direct printing without ink. Offset paper, designed for high-quality image reproduction, is optimized for offset printing processes commonly used in books, magazines, and brochures. Each paper type serves distinct purposes based on their material composition and printing technology compatibility.

Table of Comparison

| Feature | Thermal Paper | Offset Paper |

|---|---|---|

| Production Process | Coated with heat-sensitive material | Produced using traditional offset printing techniques |

| Printing Method | Thermal printing (direct heat) | Offset printing (ink transfer) |

| Image Durability | Fades over time, sensitive to heat and light | Long-lasting and stable under various conditions |

| Common Uses | Receipts, tickets, labels | Books, magazines, brochures |

| Cost | Generally lower | Generally higher |

| Environmental Impact | Contains chemicals, challenging to recycle | More environmentally friendly, easier to recycle |

Introduction to Thermal Paper and Offset Paper

Thermal paper is a heat-sensitive paper coated with a chemical layer that changes color when exposed to thermal printheads, commonly used in receipts and tickets for fast, contactless printing. Offset paper, designed for offset printing processes, is typically made from high-quality fibers and features a smooth, uniform coating to ensure sharp, detailed image reproduction in commercial printing. Understanding the distinct properties and applications of thermal and offset paper is essential for selecting the appropriate substrate in printing technologies.

Key Differences Between Thermal Paper and Offset Paper

Thermal paper features a heat-sensitive coating that produces images when exposed to thermal printheads, making it ideal for receipts and labels, while offset paper is designed for high-quality ink absorption in traditional offset printing processes. Thermal paper typically offers smooth, glossy finishes with limited archival durability, whereas offset paper provides a matte or uncoated surface with superior longevity and color fidelity. The distinct composition and printing technologies of thermal and offset papers directly influence their applications, durability, and appearance.

Composition and Manufacturing Process

Thermal paper features a heat-sensitive coating composed primarily of leuco dyes and developers, applied through a specialized coating process that enables image formation without ink. Offset paper is made from cellulose fibers, typically derived from wood pulp, produced via mechanical or chemical pulping and finished with calcium carbonate or kaolin coatings to enhance print quality. The manufacturing of thermal paper involves precise layering of reactive chemicals, whereas offset paper relies on controlled fiber processing and surface treatments to optimize ink absorption and durability.

Print Quality and Image Durability

Thermal paper offers sharp, high-contrast images ideal for receipts but tends to fade quickly under heat or light exposure, compromising long-term image durability. Offset paper, used in traditional printing, provides superior print quality with vibrant color reproduction and greater resistance to fading, resulting in longer-lasting images. Selecting offset paper ensures enhanced image clarity and durability, essential for archival documents and professional-quality prints.

Cost Comparison: Thermal vs Offset Paper

Thermal paper typically costs more per roll due to its specialized heat-sensitive coating compared to offset paper, which is generally less expensive and widely used for traditional printing. While offset paper requires ink and printing plates, increasing operational expenses, thermal paper eliminates ink costs but demands higher raw material investment. Businesses must weigh the upfront cost of thermal paper against the ongoing ink and maintenance expenses associated with offset printing to determine the most cost-effective choice.

Common Applications and Use Cases

Thermal paper is commonly used in receipts, tickets, and labels where quick, heat-based printing is required, especially in retail, hospitality, and healthcare industries. Offset paper is preferred for high-quality printing projects such as books, magazines, brochures, and promotional materials, benefiting from its superior ink absorption and durability. Both paper types meet distinct needs: thermal paper excels in speed and convenience for on-demand prints, while offset paper provides long-lasting, vibrant imagery for professional publications.

Environmental Impact and Sustainability

Thermal paper contains a chemical coating that can release harmful substances like bisphenol A (BPA), posing environmental hazards during disposal and recycling, while offset paper is more commonly recycled and generally has lower toxicity. Offset paper is often produced from sustainably managed forests and can be certified by organizations such as FSC or PEFC, enhancing its environmental credentials compared to thermal paper. The energy consumption and carbon footprint for manufacturing offset paper are typically lower, making it a more sustainable choice in print material selection.

Handling and Storage Requirements

Thermal paper requires careful handling to prevent exposure to heat, light, and humidity, which can cause the coating to darken or degrade, compromising print quality. Offset paper is more tolerant to environmental conditions but must be stored in a dry, cool environment to avoid warping or moisture damage that affects print performance. Both types benefit from storage in controlled settings with stable temperature and humidity to maintain optimal print results.

Lifespan and Sensitivity to External Factors

Thermal paper exhibits a shorter lifespan compared to offset paper due to its heat-sensitive coating, which tends to degrade when exposed to sunlight, heat, and humidity, causing the printed images to fade over time. Offset paper, made from more durable fibers and treated to resist moisture and UV exposure, maintains print quality for years, making it ideal for archival purposes. Sensitivity to external factors like temperature and humidity is substantially higher in thermal paper, requiring careful storage conditions to preserve legibility.

Choosing the Right Paper for Your Business Needs

Thermal paper offers fast, clear printing ideal for receipts and labels, while offset paper provides superior durability and color fidelity for high-quality prints such as brochures and magazines. Businesses must evaluate factors like print volume, durability requirements, and cost-efficiency to determine the optimal paper choice. Selecting the right paper improves product presentation, reduces waste, and enhances customer satisfaction by aligning print quality with usage demands.

Thermal Paper vs Offset Paper Infographic

materialdif.com

materialdif.com