Wet strength paper offers superior durability and resistance to moisture compared to standard paper, making it ideal for applications where exposure to water or humidity is frequent. Unlike standard paper, which weakens and tears easily when wet, wet strength paper maintains its integrity, ensuring longer-lasting performance. This enhanced toughness is achieved through special additives that reinforce the paper fibers without compromising flexibility or print quality.

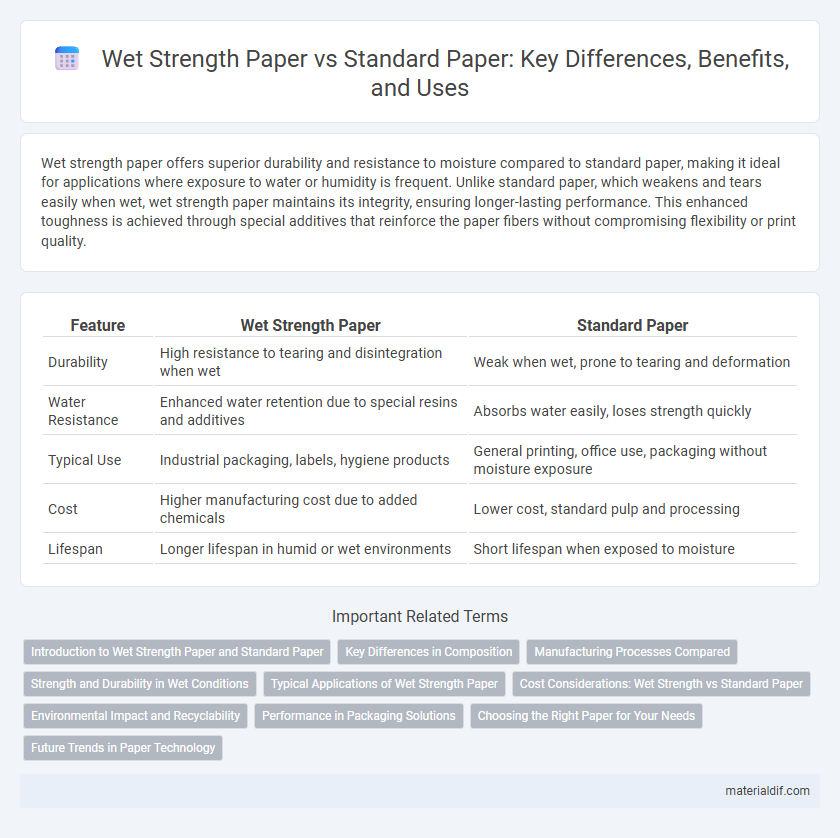

Table of Comparison

| Feature | Wet Strength Paper | Standard Paper |

|---|---|---|

| Durability | High resistance to tearing and disintegration when wet | Weak when wet, prone to tearing and deformation |

| Water Resistance | Enhanced water retention due to special resins and additives | Absorbs water easily, loses strength quickly |

| Typical Use | Industrial packaging, labels, hygiene products | General printing, office use, packaging without moisture exposure |

| Cost | Higher manufacturing cost due to added chemicals | Lower cost, standard pulp and processing |

| Lifespan | Longer lifespan in humid or wet environments | Short lifespan when exposed to moisture |

Introduction to Wet Strength Paper and Standard Paper

Wet strength paper is engineered to maintain its integrity and durability when exposed to moisture, using resins like urea-formaldehyde or melamine-formaldehyde to enhance fiber bonding. Standard paper, made primarily from cellulose fibers, lacks these additives, causing it to weaken and disintegrate upon contact with water. The distinction in chemical treatments and fiber bonding directly impacts their applications, with wet strength paper favored for packaging and labeling in humid environments.

Key Differences in Composition

Wet strength paper contains synthetic resins such as polyamide-epichlorohydrin (PAE) or melamine-formaldehyde to maintain durability and integrity when exposed to moisture, unlike standard paper which relies primarily on cellulose fibers alone. The cross-linking agents in wet strength paper create strong covalent bonds between fibers, enhancing resistance to water and preventing disintegration. Standard paper, in contrast, lacks these chemical additives, resulting in diminished strength and faster breakdown upon wetting.

Manufacturing Processes Compared

Wet strength paper incorporates synthetic adhesives like polyamide-epichlorohydrin (PAE) during the wet end of the papermaking process, enhancing fiber bonding and water resistance. In contrast, standard paper manufacturing relies primarily on hydrogen bonding and natural fibers without additives, resulting in limited durability when exposed to moisture. The integration of wet strength resins requires precise control of pH, temperature, and drying conditions to ensure optimal performance and longevity.

Strength and Durability in Wet Conditions

Wet strength paper exhibits significantly enhanced tensile strength and durability when exposed to moisture, retaining its integrity without disintegration. Standard paper, lacking reinforced fibers or chemical additives, weakens rapidly upon wetting, leading to easy tearing and loss of structural stability. The incorporation of wet strength resins in wet strength paper ensures resistance to water-induced damage, making it ideal for packaging, labels, and applications requiring moisture exposure.

Typical Applications of Wet Strength Paper

Wet strength paper is commonly used in applications requiring durability under moisture exposure, including food packaging, grocery bags, and labels for beverages and detergents. It is essential in medical and industrial wipes, where resistance to tearing and disintegration is critical. This specialized paper maintains structural integrity in wet conditions, making it ideal for outdoor and sanitary products.

Cost Considerations: Wet Strength vs Standard Paper

Wet strength paper typically incurs higher production costs due to the use of specialized resins or additives that enhance durability when exposed to moisture. Standard paper, lacking these reinforcements, is generally more affordable but offers limited resistance to water, making it unsuitable for applications requiring durability in wet conditions. Evaluating cost-effectiveness depends on the intended use, with wet strength paper justifying its higher price in environments where moisture exposure is frequent.

Environmental Impact and Recyclability

Wet strength paper, enhanced with chemical additives like polyamide-epichlorohydrin resin, exhibits superior durability in moist environments but poses challenges for recyclability due to the persistent bonding agents that hinder fiber separation. Standard paper, lacking these additives, is more environmentally friendly and easier to recycle, reducing landfill waste and energy consumption in recycling processes. The choice between wet strength and standard paper significantly affects sustainability efforts, with standard paper offering a lower environmental impact through better biodegradability and higher recycling rates.

Performance in Packaging Solutions

Wet strength paper outperforms standard paper in packaging solutions due to its enhanced durability and resistance to moisture, maintaining structural integrity even under humid conditions. Its superior fiber bonding technology prevents disintegration, making it ideal for packaging products exposed to water or high humidity. This performance advantage ensures reliable protection and extends the shelf life of goods during transportation and storage.

Choosing the Right Paper for Your Needs

Wet strength paper offers superior durability and resistance to tearing when exposed to moisture, making it ideal for applications such as packaging, labels, and outdoor use. Standard paper, while more affordable and suitable for everyday printing or writing tasks, lacks the enhanced water-resistant properties necessary for wet or humid environments. Selecting the right paper depends on factors like exposure to water, intended use, and durability requirements to ensure optimal performance and cost-efficiency.

Future Trends in Paper Technology

Future trends in paper technology emphasize enhanced wet strength paper formulations using bio-based polymers and nanocellulose to improve durability in damp environments without compromising recyclability. Innovations include enzymatic cross-linking and chemical additives that increase water resistance while maintaining biodegradability, addressing sustainability demands. Advancements also target smart paper applications with embedded sensors that retain functionality under moisture exposure, expanding wet strength paper's potential in packaging and healthcare sectors.

Wet Strength Paper vs Standard Paper Infographic

materialdif.com

materialdif.com