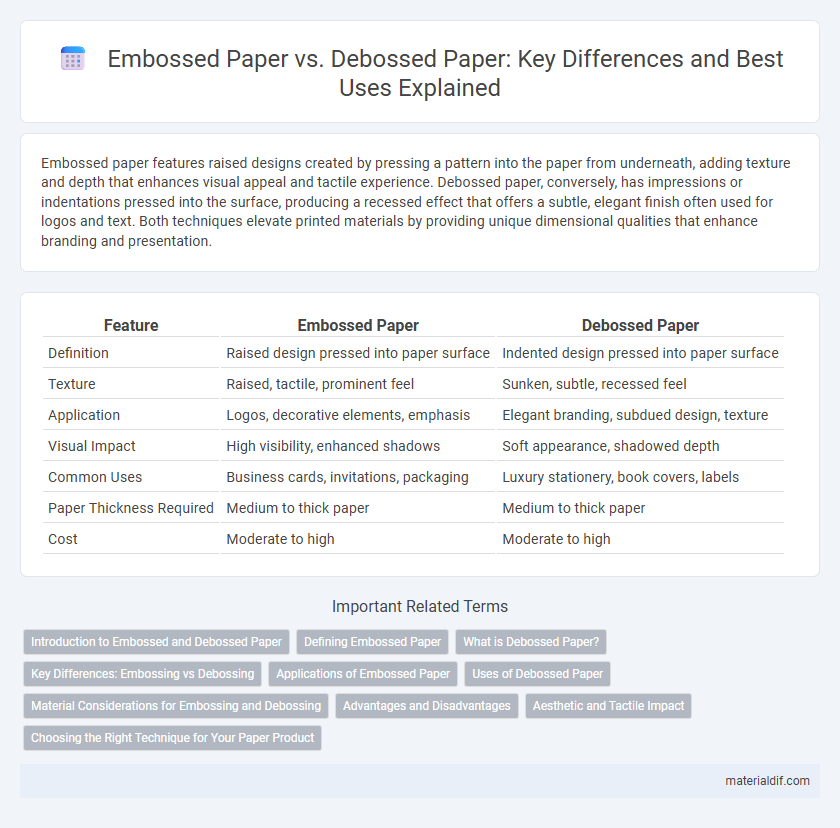

Embossed paper features raised designs created by pressing a pattern into the paper from underneath, adding texture and depth that enhances visual appeal and tactile experience. Debossed paper, conversely, has impressions or indentations pressed into the surface, producing a recessed effect that offers a subtle, elegant finish often used for logos and text. Both techniques elevate printed materials by providing unique dimensional qualities that enhance branding and presentation.

Table of Comparison

| Feature | Embossed Paper | Debossed Paper |

|---|---|---|

| Definition | Raised design pressed into paper surface | Indented design pressed into paper surface |

| Texture | Raised, tactile, prominent feel | Sunken, subtle, recessed feel |

| Application | Logos, decorative elements, emphasis | Elegant branding, subdued design, texture |

| Visual Impact | High visibility, enhanced shadows | Soft appearance, shadowed depth |

| Common Uses | Business cards, invitations, packaging | Luxury stationery, book covers, labels |

| Paper Thickness Required | Medium to thick paper | Medium to thick paper |

| Cost | Moderate to high | Moderate to high |

Introduction to Embossed and Debossed Paper

Embossed paper features raised patterns or designs created by pressing the material between two dies, enhancing tactile appeal and visual interest. Debossed paper, in contrast, involves impressions pressed into the surface, producing recessed designs that add subtle texture and sophistication. Both techniques are widely used in packaging, invitations, and branding to elevate paper aesthetics and convey quality.

Defining Embossed Paper

Embossed paper features raised designs created by pressing the material between two molds, enhancing texture and visual appeal. This technique emphasizes patterns that stand out from the surface, adding depth and dimension to printed materials. Common applications include luxury packaging, invitations, and business cards where tactile elements increase perceived value.

What is Debossed Paper?

Debossed paper features an impression pressed into the surface to create a recessed design, offering a subtle yet tactile effect that enhances text and graphics. This technique uses a metal die and counter die to stamp the paper, resulting in depth and shadow that add dimension without extra ink or foil. Often used in luxury packaging, business cards, and invitations, debossing emphasizes the material's texture and durability while conveying sophistication.

Key Differences: Embossing vs Debossing

Embossed paper features raised designs created by pressing a stencil or die from underneath, producing a three-dimensional effect that enhances texture and visual appeal. Debossed paper, in contrast, involves pressing the design into the surface, creating an indented impression that offers a subtle, tactile depth. The key difference lies in embossed paper elevating the design above the surface, while debossed paper recesses it below, influencing both the aesthetic and tactile experience of printed materials.

Applications of Embossed Paper

Embossed paper is widely used in luxury packaging, greeting cards, and business stationery to create a tactile and visually appealing texture that enhances brand perception. It is ideal for applications requiring raised patterns or logos that provide a premium, high-quality feel. Common industries utilizing embossed paper include cosmetics, confectionery, and invitation printing, where distinguished aesthetics drive consumer engagement.

Uses of Debossed Paper

Debossed paper is primarily used for elegant invitations, business cards, and packaging to create a subtle yet sophisticated impression by pressing the design into the surface. This technique enhances tactile appeal and adds a professional, high-end finish that complements minimalist and luxury branding. Debossing is favored in industries like fashion, cosmetics, and stationery where understated elegance is essential.

Material Considerations for Embossing and Debossing

Embossed paper requires a thicker, more rigid material such as cardstock or specialty papers to hold raised impressions without tearing or distorting. Debossed paper benefits from smooth, dense substrates like coated or uncoated papers to achieve sharp, recessed designs with clear detail. Both techniques demand papers with sufficient thickness, typically above 80 gsm, to ensure durability and optimal image definition during the embossing and debossing process.

Advantages and Disadvantages

Embossed paper offers a raised texture that enhances visual appeal and tactile experience, making it ideal for luxury packaging and invitations, but it may increase production costs and limit design complexity. Debossed paper creates an indented effect that adds subtle elegance and durability to prints, suitable for professional branding and stationery, yet it may lack the boldness of embossing and reduce readability in detailed designs. Both techniques provide distinctive aesthetic benefits while presenting challenges in terms of cost, design limitations, and application suitability.

Aesthetic and Tactile Impact

Embossed paper elevates design elements by creating raised patterns that enhance visual depth and tactile richness, making prints more engaging and luxurious. Debossed paper, in contrast, offers sunken impressions that provide subtle texture and a sophisticated, understated look, often conveying elegance and refinement. Both techniques significantly influence the aesthetic appeal and sensory experience of paper products, tailoring them to different branding and artistic preferences.

Choosing the Right Technique for Your Paper Product

Embossed paper raises the design above the paper surface, creating a tactile, three-dimensional effect that enhances visual appeal and luxury perception for invitations, packaging, or business cards. Debossed paper presses the design into the surface, producing a subtle, elegant impression ideal for minimalistic branding or sophisticated stationery. Selecting the right technique depends on the desired texture, visual impact, and budget considerations to ensure the paper product aligns with the brand's message and user experience.

Embossed Paper vs Debossed Paper Infographic

materialdif.com

materialdif.com