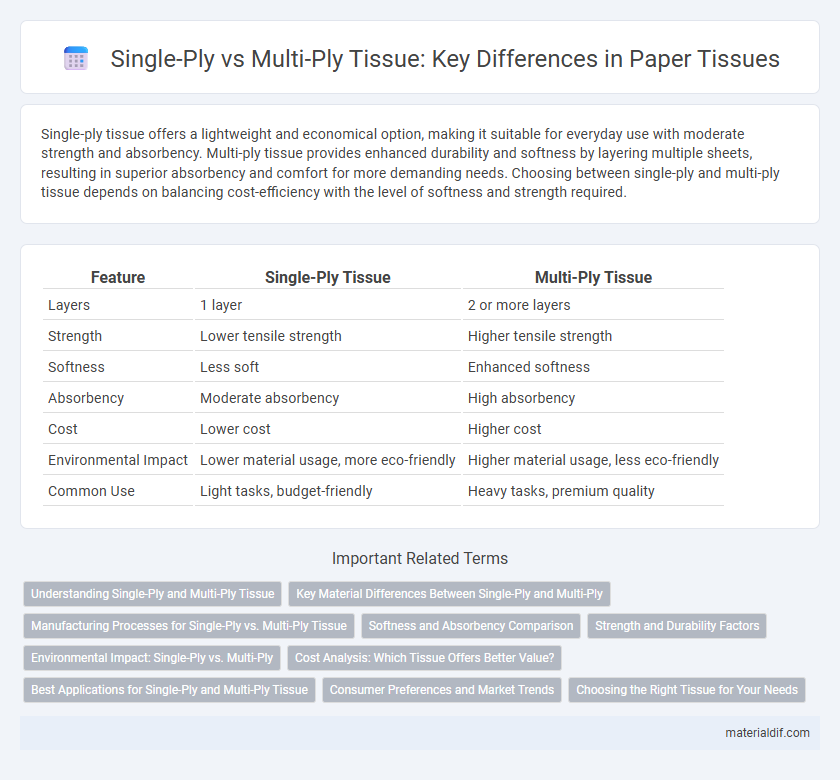

Single-ply tissue offers a lightweight and economical option, making it suitable for everyday use with moderate strength and absorbency. Multi-ply tissue provides enhanced durability and softness by layering multiple sheets, resulting in superior absorbency and comfort for more demanding needs. Choosing between single-ply and multi-ply tissue depends on balancing cost-efficiency with the level of softness and strength required.

Table of Comparison

| Feature | Single-Ply Tissue | Multi-Ply Tissue |

|---|---|---|

| Layers | 1 layer | 2 or more layers |

| Strength | Lower tensile strength | Higher tensile strength |

| Softness | Less soft | Enhanced softness |

| Absorbency | Moderate absorbency | High absorbency |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Lower material usage, more eco-friendly | Higher material usage, less eco-friendly |

| Common Use | Light tasks, budget-friendly | Heavy tasks, premium quality |

Understanding Single-Ply and Multi-Ply Tissue

Single-ply tissue consists of a single layer of paper fibers, offering a lightweight and cost-effective option primarily used for basic hygiene needs. Multi-ply tissue combines two or more layers, enhancing durability, absorbency, and softness, making it suitable for premium applications and sensitive skin. The choice between single-ply and multi-ply tissue often depends on factors such as budget, environmental impact, and user preference for texture and strength.

Key Material Differences Between Single-Ply and Multi-Ply

Single-ply tissue consists of a single layer of paper fibers, offering a thinner and more economical option with less absorbency and durability compared to multi-ply tissue. Multi-ply tissue integrates two or more layers of paper, enhancing strength, softness, and absorbency due to the increased fiber density and layering technique. The choice between single-ply and multi-ply tissue significantly impacts texture, durability, and overall user experience based on material composition and ply structure.

Manufacturing Processes for Single-Ply vs. Multi-Ply Tissue

Single-ply tissue manufacturing involves producing a single layer by embossing and calendaring to enhance softness and absorbency, optimizing fiber bonding for strength. Multi-ply tissue requires separate sheets that are individually formed and dried before being laminated together, using adhesives or thermal bonding for added durability and thickness. The manufacturing process for multi-ply tissue is more complex and energy-intensive, incorporating additional steps for alignment and ply adhesion to achieve improved strength and comfort.

Softness and Absorbency Comparison

Single-ply tissue offers a lightweight, softer texture ideal for sensitive skin but generally provides lower absorbency compared to multi-ply tissue. Multi-ply tissue, constructed with two or more layers, enhances durability and significantly increases absorbency, making it more efficient for thorough cleaning. Consumers seeking a balance between softness and performance often choose multi-ply options for their superior strength and moisture retention.

Strength and Durability Factors

Single-ply tissue offers lightweight softness but generally lacks the strength and durability found in multi-ply tissue, which combines multiple layers to enhance tear resistance and absorbency. Multi-ply tissue's reinforced structure provides superior tensile strength, making it ideal for heavy-duty use and prolonged moisture exposure. Strength factors such as ply count, fiber bonding, and material composition significantly influence tissue longevity and performance under stress.

Environmental Impact: Single-Ply vs. Multi-Ply

Single-ply tissue generally has a lower environmental impact due to reduced raw material consumption and lower energy usage in manufacturing compared to multi-ply tissue. Multi-ply tissues require more fibers and chemicals, leading to higher water usage and greater carbon emissions throughout production. Choosing single-ply options can contribute to less waste generation and improved resource efficiency in paper product consumption.

Cost Analysis: Which Tissue Offers Better Value?

Single-ply tissue typically costs less upfront, making it an economical choice for bulk purchases and reducing immediate expenses for businesses and consumers. Multi-ply tissue, while more expensive per unit, often provides greater strength and absorbency, potentially reducing the quantity needed over time and offering better long-term value. Evaluating overall cost-effectiveness requires analyzing both the price per roll and the frequency of replacement, highlighting multi-ply tissue's advantage in durability despite a higher initial investment.

Best Applications for Single-Ply and Multi-Ply Tissue

Single-ply tissue is best suited for environments with moderate usage, such as residential bathrooms and office spaces, where cost efficiency and basic softness are priorities. Multi-ply tissue excels in high-traffic commercial settings, healthcare facilities, and hospitality sectors due to its superior strength, absorbency, and comfort. Choosing between single-ply and multi-ply tissue depends on factors like budget, usage frequency, and user preference for durability and softness.

Consumer Preferences and Market Trends

Consumers increasingly favor multi-ply tissue for its superior softness and durability, driving market growth in premium segments. Single-ply tissue remains popular due to its cost-effectiveness and environmental benefits, appealing to budget-conscious and eco-aware buyers. Market trends indicate a rising demand for sustainable, high-quality multi-ply products, influencing manufacturers to innovate with biodegradable materials and enhanced textures.

Choosing the Right Tissue for Your Needs

Single-ply tissue offers a thinner, more cost-effective option suitable for everyday use and environments where frequent replacement is feasible. Multi-ply tissue provides enhanced durability and absorbency, making it ideal for sensitive skin or high-traffic areas demanding greater comfort and strength. Evaluating factors like budget, usage patterns, and user preference ensures selecting the tissue type that best aligns with specific hygiene and practical needs.

Single-Ply Tissue vs Multi-Ply Tissue Infographic

materialdif.com

materialdif.com