Cast-coated paper offers a high-gloss, mirror-like finish achieved through a hot casting process that enhances smoothness and print quality, making it ideal for premium packaging and labels. Machine-coated paper features a thinner coating applied during the papermaking process, providing a more economical option with good printability and a matte to semi-gloss finish suitable for magazines and catalogs. Choosing between cast-coated and machine-coated paper depends on the desired surface aesthetics, durability, and cost considerations for the intended application.

Table of Comparison

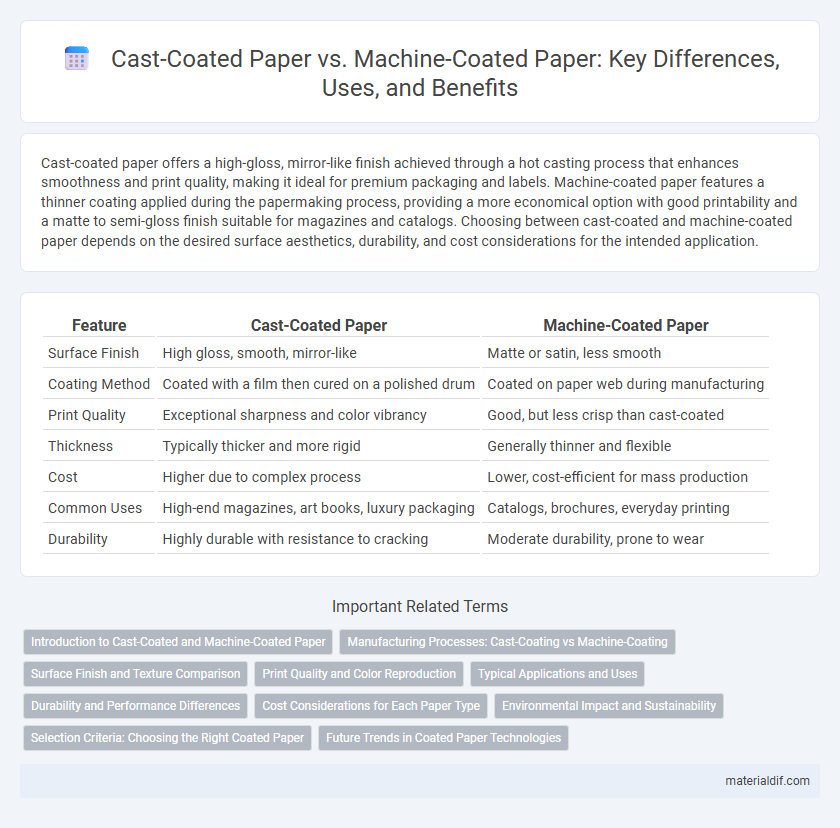

| Feature | Cast-Coated Paper | Machine-Coated Paper |

|---|---|---|

| Surface Finish | High gloss, smooth, mirror-like | Matte or satin, less smooth |

| Coating Method | Coated with a film then cured on a polished drum | Coated on paper web during manufacturing |

| Print Quality | Exceptional sharpness and color vibrancy | Good, but less crisp than cast-coated |

| Thickness | Typically thicker and more rigid | Generally thinner and flexible |

| Cost | Higher due to complex process | Lower, cost-efficient for mass production |

| Common Uses | High-end magazines, art books, luxury packaging | Catalogs, brochures, everyday printing |

| Durability | Highly durable with resistance to cracking | Moderate durability, prone to wear |

Introduction to Cast-Coated and Machine-Coated Paper

Cast-coated paper features a high-gloss surface achieved by pressing the paper between heated rollers and a polished casting drum, resulting in superior smoothness and print quality ideal for high-end packaging and labels. Machine-coated paper is produced by applying a coating layer directly on the paper machine, offering a more cost-effective option with good printability and a matte or satin finish primarily used for magazines, catalogs, and advertising materials. Understanding the manufacturing processes and surface properties of cast-coated versus machine-coated paper helps in selecting the right paper type for specific printing and packaging needs.

Manufacturing Processes: Cast-Coating vs Machine-Coating

Cast-coated paper undergoes a unique manufacturing process involving the application of a coating layer while the paper is pressed against a highly polished, heated roller, resulting in a smooth, glossy surface with superior print quality. Machine-coated paper is produced by applying coating materials using blade or rod coaters directly on the moving paper web, offering efficient bulk production with consistent finish but less gloss and surface uniformity compared to cast-coated paper. The cast-coating process generates higher gloss and improved ink holdout due to the controlled cooling and solidification on the polished drum, while machine coating prioritizes speed and cost-efficiency suitable for mass production.

Surface Finish and Texture Comparison

Cast-coated paper features a smooth, high-gloss surface achieved by pressing the paper against a polished metal drum, resulting in a mirror-like finish ideal for vibrant image reproduction. Machine-coated paper has a less reflective surface with a softer texture due to coating applied on the paper machine, providing moderate gloss and a more natural feel. The surface finish of cast-coated paper enhances sharpness and color density, while machine-coated paper offers better suitability for text readability and tactile impressions.

Print Quality and Color Reproduction

Cast-coated paper delivers superior print quality and vibrant color reproduction due to its ultra-smooth, high-gloss surface created through a casting process on a polished cylinder. Machine-coated paper, while more cost-effective, typically has a less uniform coating leading to moderate gloss and slightly muted color depth. The enhanced surface uniformity of cast-coated paper allows for sharper image detail and richer, more accurate colors, making it ideal for high-end printing applications.

Typical Applications and Uses

Cast-coated paper excels in high-quality graphic applications such as luxury packaging, art books, and photographic prints due to its smooth, glossy finish and enhanced color reproduction. Machine-coated paper is commonly used for mass printing tasks including magazines, catalogs, and direct mail because of its cost-effectiveness and versatility in producing consistent surface textures. Both types serve distinct market needs by balancing aesthetic appeal and production efficiency in printed materials.

Durability and Performance Differences

Cast-coated paper exhibits superior durability due to its glassy, smooth surface achieved through a heat-curing process, which enhances resistance to abrasion and moisture. Machine-coated paper offers a more economical solution with a smoother finish than uncoated paper but lacks the hardness and scuff resistance of cast-coated variants. Performance differences are notable in high-end printing applications, where cast-coated paper delivers sharper images and greater longevity under handling stress.

Cost Considerations for Each Paper Type

Cast-coated paper typically incurs higher production costs due to its intensive manufacturing process involving heat and pressure to achieve a glossy, smooth finish. Machine-coated paper is generally more cost-effective, benefiting from a simpler coating process that applies coating inline during paper production, reducing labor and energy expenses. The choice between cast-coated and machine-coated paper largely depends on budget constraints and the intended quality of the final printed product.

Environmental Impact and Sustainability

Cast-coated paper typically involves a glossy, plastic film coating that enhances surface smoothness and print quality but often reduces recyclability and increases environmental impact due to its non-biodegradable components. Machine-coated paper uses a more uniform application of coatings during production, allowing for easier recycling and lower ecological footprint because it generally employs water-based coatings and fewer synthetic additives. Lifecycle assessments indicate machine-coated paper offers better sustainability profiles by minimizing waste and energy consumption in manufacturing, making it a preferred choice for eco-conscious printing applications.

Selection Criteria: Choosing the Right Coated Paper

Cast-coated paper offers a highly glossy surface with superior smoothness and excellent printability, making it ideal for high-quality image reproduction in premium packaging and brochures. Machine-coated paper provides a more cost-effective solution with moderate gloss and smoothness, suitable for mass-market publications and everyday printing needs. Selection criteria hinge on desired finish quality, print requirements, budget constraints, and specific application demands.

Future Trends in Coated Paper Technologies

Future trends in coated paper technologies emphasize enhanced sustainability and performance, with innovations like biodegradable cast-coated papers and advanced machine-coated substrates designed for improved print quality and durability. Developments in nanocoatings and eco-friendly polymers aim to reduce environmental impact while offering superior moisture resistance and gloss. Integration of smart coatings incorporating functional properties such as antiviral surfaces is expected to reshape both cast-coated and machine-coated paper markets.

Cast-coated paper vs Machine-coated paper Infographic

materialdif.com

materialdif.com