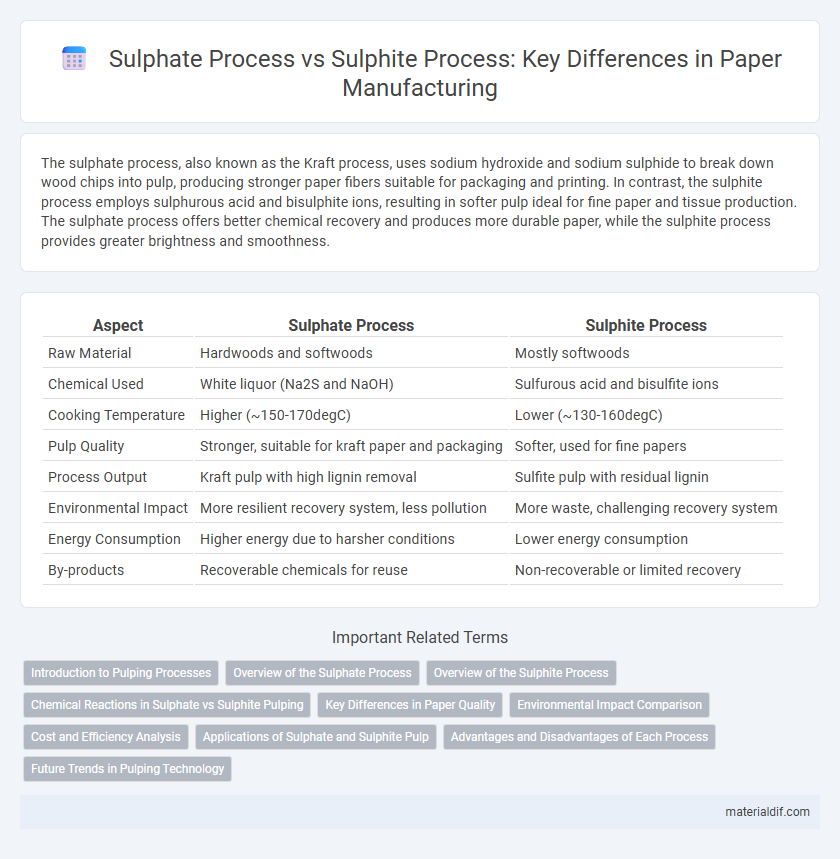

The sulphate process, also known as the Kraft process, uses sodium hydroxide and sodium sulphide to break down wood chips into pulp, producing stronger paper fibers suitable for packaging and printing. In contrast, the sulphite process employs sulphurous acid and bisulphite ions, resulting in softer pulp ideal for fine paper and tissue production. The sulphate process offers better chemical recovery and produces more durable paper, while the sulphite process provides greater brightness and smoothness.

Table of Comparison

| Aspect | Sulphate Process | Sulphite Process |

|---|---|---|

| Raw Material | Hardwoods and softwoods | Mostly softwoods |

| Chemical Used | White liquor (Na2S and NaOH) | Sulfurous acid and bisulfite ions |

| Cooking Temperature | Higher (~150-170degC) | Lower (~130-160degC) |

| Pulp Quality | Stronger, suitable for kraft paper and packaging | Softer, used for fine papers |

| Process Output | Kraft pulp with high lignin removal | Sulfite pulp with residual lignin |

| Environmental Impact | More resilient recovery system, less pollution | More waste, challenging recovery system |

| Energy Consumption | Higher energy due to harsher conditions | Lower energy consumption |

| By-products | Recoverable chemicals for reuse | Non-recoverable or limited recovery |

Introduction to Pulping Processes

The sulphate process, also known as the kraft process, utilizes sodium hydroxide and sodium sulfide to break down lignin and separate cellulose fibers, producing strong and high-yield pulp ideal for paper production. In contrast, the sulphite process employs sulfite ions in an acidic solution, effectively dissolving lignin but resulting in weaker pulp with limited applications. Both pulping methods are fundamental in the paper industry, with the sulphate process dominating due to its ability to handle a wider range of wood types and produce higher-quality paper products.

Overview of the Sulphate Process

The sulphate process, also known as the kraft process, is the dominant method for producing chemical pulp from wood and other lignocellulosic materials. It uses a strong alkaline solution of sodium hydroxide and sodium sulfide to break down lignin and separate cellulose fibers efficiently, resulting in higher pulp strength and yield compared to the sulphite process. This process accommodates a wider variety of raw materials and supports chemical recovery, making it economically and environmentally advantageous in large-scale pulp production.

Overview of the Sulphite Process

The sulphite process utilizes sulphurous acid and bisulfite ions to break down lignin in wood pulp, producing a chemically pulped material with high brightness and strength. This method is particularly effective for hardwoods and yields pulp with lower residual lignin compared to the sulphate process. Key advantages include enhanced pulp quality for specialty papers and improved bleaching efficiency, making it a preferred choice for fine printing and writing papers.

Chemical Reactions in Sulphate vs Sulphite Pulping

The sulphate process, also known as the kraft process, involves alkaline pulping where lignin is broken down by sodium hydroxide and sodium sulfide, producing stronger pulp fibers. In contrast, the sulphite process uses acidic conditions with sulfur dioxide and bisulfite ions to dissolve lignin, resulting in pulp with higher brightness but lower strength. Chemical reactions in the sulphate process generate thiol groups that enhance delignification, while the sulphite process primarily relies on sulfonation to increase pulp solubility.

Key Differences in Paper Quality

The Sulphate process produces stronger, more durable paper due to its ability to break down tougher hardwoods, resulting in higher-quality kraft pulp with enhanced tensile strength and resistance to moisture. In contrast, the Sulphite process yields paper with superior brightness and a smoother texture but generally lower mechanical strength, making it ideal for fine printing and writing papers. Paper quality differences hinge on the chemical treatment of lignin removal, with the Sulphate process favoring strength and durability and the Sulphite process emphasizing brightness and softness.

Environmental Impact Comparison

The sulphate process generates less harmful wastewater compared to the sulphite process, producing lignin byproducts that are easier to treat and recycle. Sulphite process effluents contain higher concentrations of sulfite and organic acids, leading to greater toxicity and longer biodegradation times in aquatic environments. Sulphate process mills typically achieve better air emission controls, reducing sulfur dioxide and foul odors, which contributes to a lower overall environmental footprint.

Cost and Efficiency Analysis

The sulphate process, widely used in pulp production, typically incurs higher chemical costs but offers superior yield and product strength compared to the sulphite process. Sulphite pulping tends to be less energy-intensive and has lower chemical expenses, yet it results in lower pulp yield and weaker fiber quality. Cost efficiency in industrial applications favors the sulphate process due to its ability to utilize a broader range of wood types and produce higher-value pulp despite the initial expense.

Applications of Sulphate and Sulphite Pulp

Sulphate pulp, produced through the kraft process, is primarily used in the manufacture of strong paper products such as packaging materials, high-strength paperboard, and specialty papers due to its superior fiber strength and chemical resistance. Sulphite pulp, obtained from the sulphite process, is favored for producing softer, finer papers like tissue, printing, and writing papers because of its excellent brightness and smoothness. Both pulps serve distinct industry roles, with sulphate pulp dominating in applications requiring durability, while sulphite pulp excels in quality-focused, lighter-weight paper products.

Advantages and Disadvantages of Each Process

The sulphate process, also known as the kraft process, offers higher pulp strength and the ability to process a wider range of wood types, but it requires more energy and produces odorous sulfur compounds. The sulphite process produces pulp that is easier to bleach and yields smoother paper surfaces, yet it has limitations in raw material flexibility and generates more acidic waste. Each process impacts environmental management differently, with the sulphate process favored for its robustness in industrial applications and the sulphite process preferred for specialty papers with tighter quality control.

Future Trends in Pulping Technology

Advancements in pulping technology emphasize sustainable and energy-efficient methods, with the sulphate process gaining prominence due to its ability to produce stronger pulp with higher yield from hardwood and softwood. Research in enzymatic and bio-based additives aims to reduce chemical consumption and environmental impact in both sulphate and sulphite processes. Future trends include integrating digital monitoring systems to optimize chemical usage and improve process control, enhancing overall production efficiency and pulp quality.

Sulphate Process vs Sulphite Process Infographic

materialdif.com

materialdif.com