Two-sided coating on paper enhances durability and print quality by providing a smooth, uniform surface on both sides, making it ideal for double-sided printing applications. One-sided coating is more cost-effective and suitable for single-sided prints where only one side requires a high-quality finish. Choosing between two-sided and one-sided coated paper depends on the specific printing needs and budget considerations.

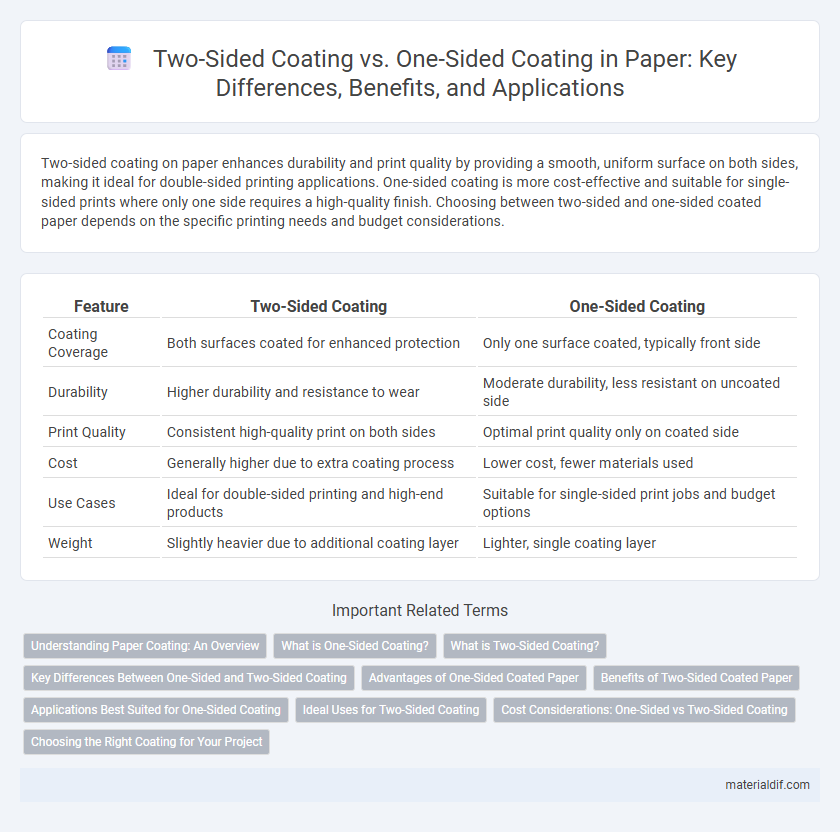

Table of Comparison

| Feature | Two-Sided Coating | One-Sided Coating |

|---|---|---|

| Coating Coverage | Both surfaces coated for enhanced protection | Only one surface coated, typically front side |

| Durability | Higher durability and resistance to wear | Moderate durability, less resistant on uncoated side |

| Print Quality | Consistent high-quality print on both sides | Optimal print quality only on coated side |

| Cost | Generally higher due to extra coating process | Lower cost, fewer materials used |

| Use Cases | Ideal for double-sided printing and high-end products | Suitable for single-sided print jobs and budget options |

| Weight | Slightly heavier due to additional coating layer | Lighter, single coating layer |

Understanding Paper Coating: An Overview

Two-sided coating enhances paper durability and print quality by applying coating on both faces, optimizing opacity and smoothness, whereas one-sided coating targets only the print surface for cost-effective improvements. Coating substances like clay, latex, or calcium carbonate influence gloss, brightness, and ink absorption, critical for high-resolution printing. Understanding the differences helps in selecting the right paper type for specific printing needs, balancing performance and budget.

What is One-Sided Coating?

One-sided coating refers to the application of a coating layer exclusively on one surface of a paper sheet, enhancing properties such as printability, gloss, and barrier protection on that specific side. This technique is commonly used in packaging and label papers where the appearance or functional performance is required on just one face. Compared to two-sided coating, one-sided coating reduces production costs and material usage while targeting performance on the intended surface.

What is Two-Sided Coating?

Two-sided coating refers to the process where both sides of a paper sheet receive a layer of coating, enhancing print quality, opacity, and smoothness on each surface. This method improves paper durability and appearance, making it ideal for high-end printing applications such as magazines and brochures. In contrast to one-sided coating, two-sided coating offers balanced performance and aesthetic uniformity on both sides of the paper.

Key Differences Between One-Sided and Two-Sided Coating

One-sided coating applies a protective or functional layer exclusively on one surface of the paper, optimizing cost and weight for applications like printing and packaging where only one side requires enhancement. Two-sided coating involves coating both sides of the paper, improving durability, printability, and appearance on both surfaces, which is essential for high-quality double-sided printing and specialty products. The key differences lie in their functional applications, cost implications, and performance, with two-sided coating offering superior resistance and visual appeal but at a higher production cost compared to one-sided coating.

Advantages of One-Sided Coated Paper

One-sided coated paper offers enhanced print quality with sharper images and more vibrant colors due to the specialized coating on one side only. This type of paper provides better ink absorption and drying times, which increases printing efficiency and reduces smudging. It is also more cost-effective and environmentally friendly as it requires less coating material compared to two-sided coated paper.

Benefits of Two-Sided Coated Paper

Two-sided coated paper offers superior print quality on both sides, making it ideal for brochures, magazines, and double-sided printing projects that require vibrant colors and sharp details. This coating enhances durability and resistance to smudging or fading, ensuring long-lasting presentation and professional appearance. Furthermore, two-sided coated paper reduces paper waste by enabling double-sided use, promoting eco-friendly printing practices and cost savings.

Applications Best Suited for One-Sided Coating

One-sided coating is ideal for applications requiring printability, durability, and functional properties on a single surface, such as labels, packaging, and printing papers. This coating technique enhances image quality, ink adhesion, and resistance to abrasion on the coated side, making it suitable for high-performance printing and protective overlays. Products like magazine covers, book pages, and flexible packaging commonly utilize one-sided coating for optimal cost-efficiency and material performance.

Ideal Uses for Two-Sided Coating

Two-sided coating paper offers enhanced durability and moisture resistance, making it ideal for packaging applications requiring protection on both surfaces, such as food wrappers and medical packaging. This coating ensures print clarity on both sides, which is crucial for double-sided printing in marketing materials and brochures. Industries benefiting from two-sided coated paper include pharmaceuticals, food service, and graphic design, where high-quality aesthetics and functional performance are essential.

Cost Considerations: One-Sided vs Two-Sided Coating

Two-sided coating generally incurs higher material and processing costs compared to one-sided coating due to the additional layer application and curing requirements. One-sided coating reduces production time and resource consumption, making it more cost-effective for projects with limited functional demands. However, two-sided coatings offer enhanced durability and performance benefits that may justify the increased investment in specific industrial or packaging applications.

Choosing the Right Coating for Your Project

Two-sided coating provides enhanced durability and improved moisture resistance, making it ideal for applications requiring extra protection on both sides of the paper. One-sided coating is typically more cost-effective and sufficient for projects where only one surface needs to be glossy or water-resistant, such as flyers or brochures. Selecting the right coating depends on the project's functional requirements, budget constraints, and the desired aesthetic effect.

Two-sided coating vs One-sided coating Infographic

materialdif.com

materialdif.com