Lightweight coated paper offers a smooth, glossy finish that enhances color vibrancy and sharpness, making it ideal for high-quality printing and detailed graphics. In contrast, lightweight uncoated paper provides a more natural texture with better absorbency, which improves handwriting and allows for quicker drying of inks. Choosing between the two depends on the desired visual impact and functional use, with coated paper favoring polished presentations and uncoated paper supporting versatility and ease of use.

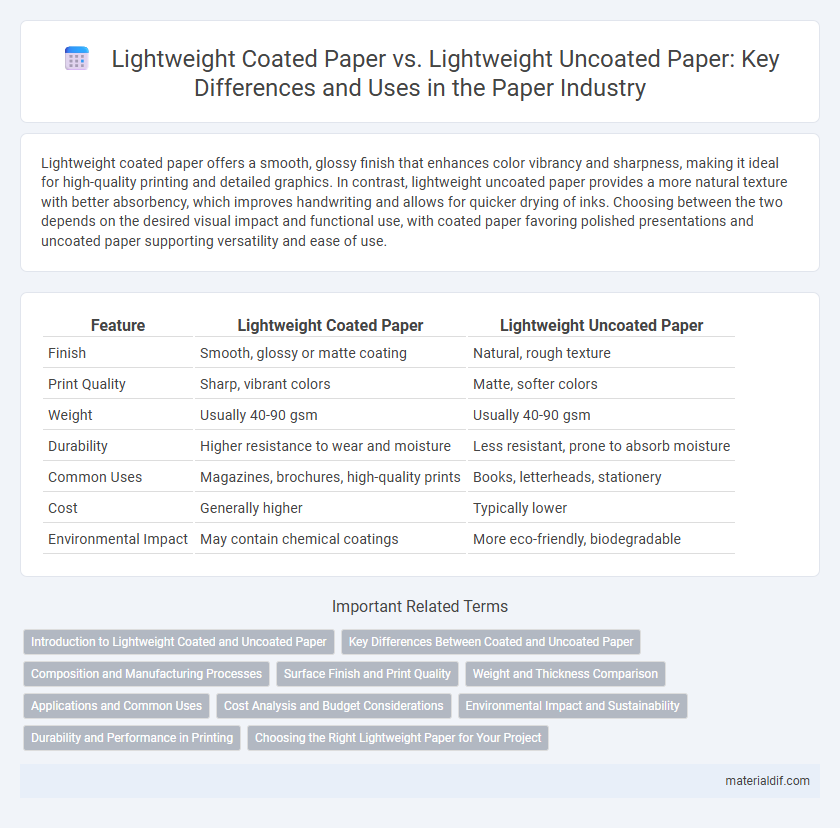

Table of Comparison

| Feature | Lightweight Coated Paper | Lightweight Uncoated Paper |

|---|---|---|

| Finish | Smooth, glossy or matte coating | Natural, rough texture |

| Print Quality | Sharp, vibrant colors | Matte, softer colors |

| Weight | Usually 40-90 gsm | Usually 40-90 gsm |

| Durability | Higher resistance to wear and moisture | Less resistant, prone to absorb moisture |

| Common Uses | Magazines, brochures, high-quality prints | Books, letterheads, stationery |

| Cost | Generally higher | Typically lower |

| Environmental Impact | May contain chemical coatings | More eco-friendly, biodegradable |

Introduction to Lightweight Coated and Uncoated Paper

Lightweight coated paper features a smooth, glossy finish achieved by applying a thin layer of coating materials such as clay or latex, enhancing print quality and color vibrancy while maintaining low basis weight. In contrast, lightweight uncoated paper lacks this surface coating, resulting in a more porous texture that absorbs ink differently, offering a natural, matte appearance favored for readability and tactile appeal. Both paper types are designed to balance durability and lightness, catering to various printing and publishing needs where weight reduction is critical.

Key Differences Between Coated and Uncoated Paper

Lightweight coated paper features a smooth, glossy surface achieved by applying a coating of clay or other substances, enhancing print quality, color vibrancy, and sharpness. In contrast, lightweight uncoated paper lacks this coating, resulting in a more porous, matte finish that absorbs ink differently, making it ideal for writing and easy reading. Key differences lie in texture, print clarity, and applications, with coated paper favored for high-quality graphics and uncoated paper preferred for stationery and books.

Composition and Manufacturing Processes

Lightweight coated paper features a base paper layer coated with a mixture of pigments and binders, enhancing smoothness, brightness, and ink holdout, achieved through processes like blade or air-knife coating. Lightweight uncoated paper consists solely of natural fibers without additional coatings, resulting in a more porous surface and matte finish, produced by traditional papermaking methods including calendaring for surface smoothing. The coated variant requires more complex manufacturing steps, increasing cost and improving print quality, while uncoated paper offers flexibility and cost-efficiency with simpler production techniques.

Surface Finish and Print Quality

Lightweight coated paper features a smooth, glossy surface finish that enhances print quality by providing sharp image detail and vibrant color reproduction, ideal for high-resolution graphics. In contrast, lightweight uncoated paper has a natural, porous surface that absorbs ink more readily, leading to a softer, matte appearance and less precise print clarity. The choice between coated and uncoated paper significantly impacts visual sharpness and color vibrancy in printed materials.

Weight and Thickness Comparison

Lightweight coated paper typically has a smoother finish and a moderately higher weight ranging from 60 to 90 gsm, while lightweight uncoated paper usually falls between 50 to 80 gsm with a more porous texture. The thickness of coated paper is generally slightly greater due to the coating layer, averaging around 70 to 100 microns, compared to uncoated paper which ranges from 60 to 90 microns. This difference in weight and thickness significantly impacts print quality and paper durability, with coated paper providing enhanced image sharpness and protection.

Applications and Common Uses

Lightweight coated paper is widely used for high-quality printing applications such as magazines, brochures, and direct mail due to its smooth surface and enhanced color vibrancy. In contrast, lightweight uncoated paper is preferred for everyday printing needs like office stationery, books, and letterheads because of its natural texture and better ink absorption. Both types serve distinct purposes, with coated paper providing a polished finish and uncoated paper offering a more natural look and feel.

Cost Analysis and Budget Considerations

Lightweight coated paper generally incurs higher production and purchase costs due to the added coating process, which enhances print quality and brightness but increases material expenses. In contrast, lightweight uncoated paper offers a more budget-friendly option with lower manufacturing costs, suitable for projects where cost-efficiency outweighs the need for premium finish. Businesses must weigh the balance between initial investment and desired print appearance when selecting between coated and uncoated lightweight paper for budget-conscious decisions.

Environmental Impact and Sustainability

Lightweight coated paper typically involves higher energy and chemical use during production, resulting in a greater environmental footprint compared to lightweight uncoated paper, which generally requires fewer resources and emits less pollution. Uncoated paper tends to be more easily recyclable and biodegradable, enhancing its sustainability profile. Selecting uncoated options supports reduced carbon emissions and lowers waste impact across the paper lifecycle.

Durability and Performance in Printing

Lightweight coated paper exhibits superior durability and enhanced print performance due to its smooth, sealed surface that resists smudging and provides sharp, vibrant images. In contrast, lightweight uncoated paper offers a more natural texture but tends to absorb ink, resulting in less crisp prints and increased susceptibility to wear and tear. For high-quality printing with longevity, coated paper remains the preferred choice in commercial and artistic applications.

Choosing the Right Lightweight Paper for Your Project

Lightweight coated paper offers a smooth finish and excellent print quality, making it ideal for projects requiring vibrant colors and sharp images, such as brochures and flyers. In contrast, lightweight uncoated paper provides a natural texture and superior ink absorption, which enhances writing and readability, suitable for stationery and letterheads. Selecting the right lightweight paper depends on the project's purpose, desired appearance, and the type of printing method used.

Lightweight Coated Paper vs Lightweight Uncoated Paper Infographic

materialdif.com

materialdif.com