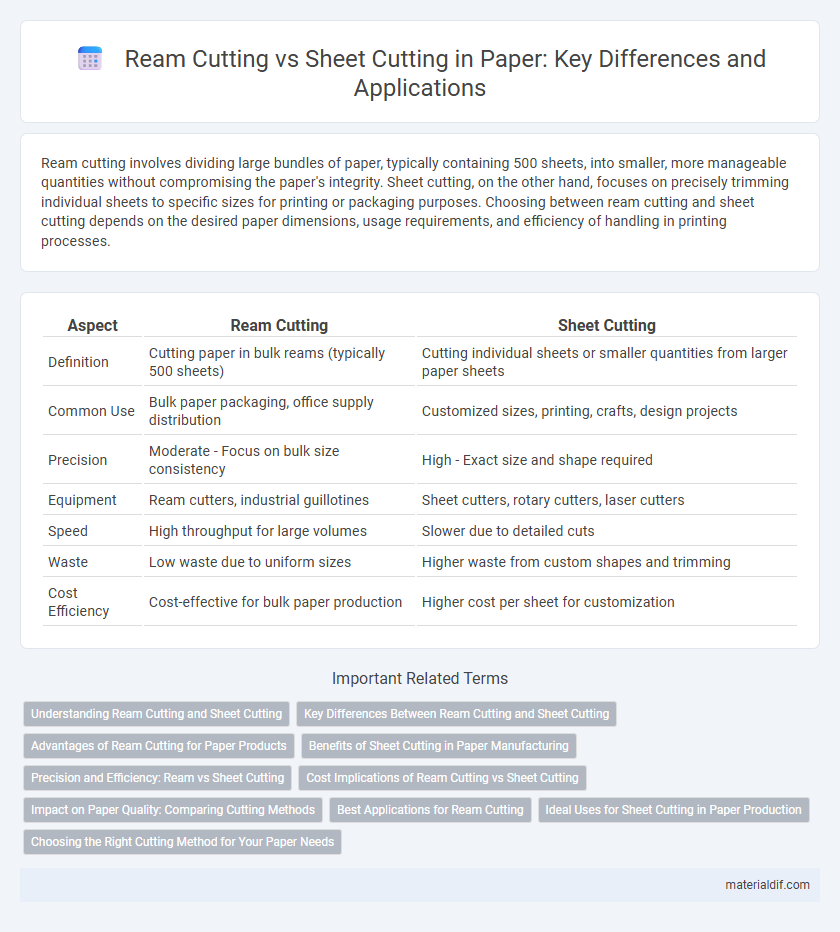

Ream cutting involves dividing large bundles of paper, typically containing 500 sheets, into smaller, more manageable quantities without compromising the paper's integrity. Sheet cutting, on the other hand, focuses on precisely trimming individual sheets to specific sizes for printing or packaging purposes. Choosing between ream cutting and sheet cutting depends on the desired paper dimensions, usage requirements, and efficiency of handling in printing processes.

Table of Comparison

| Aspect | Ream Cutting | Sheet Cutting |

|---|---|---|

| Definition | Cutting paper in bulk reams (typically 500 sheets) | Cutting individual sheets or smaller quantities from larger paper sheets |

| Common Use | Bulk paper packaging, office supply distribution | Customized sizes, printing, crafts, design projects |

| Precision | Moderate - Focus on bulk size consistency | High - Exact size and shape required |

| Equipment | Ream cutters, industrial guillotines | Sheet cutters, rotary cutters, laser cutters |

| Speed | High throughput for large volumes | Slower due to detailed cuts |

| Waste | Low waste due to uniform sizes | Higher waste from custom shapes and trimming |

| Cost Efficiency | Cost-effective for bulk paper production | Higher cost per sheet for customization |

Understanding Ream Cutting and Sheet Cutting

Ream cutting involves dividing a large quantity of paper, typically 500 sheets per ream, into manageable reams for easier storage and handling. Sheet cutting refers to the process of cutting large paper sheets into specific sizes or formats required for printing or packaging. Understanding these methods is crucial for optimizing paper utilization and minimizing waste during production.

Key Differences Between Ream Cutting and Sheet Cutting

Ream cutting involves dividing large paper blocks, typically 500 sheets bundled together, into smaller, manageable reams, enhancing bulk handling efficiency for printing and packaging industries. Sheet cutting precisely trims individual sheets to specific dimensions, catering to customized printing and craft applications where size accuracy is critical. The key differences lie in their scale and precision: ream cutting emphasizes volume and bulk processing, while sheet cutting prioritizes exact size specifications for end-use requirements.

Advantages of Ream Cutting for Paper Products

Ream cutting enhances production efficiency by minimizing paper handling and reducing waste, making it ideal for bulk paper processing. It ensures uniform sheet sizes and consistent quality, which improves printing accuracy and reduces machine downtime. This method also lowers labor costs and increases throughput, proving advantageous for high-volume paper product manufacturing.

Benefits of Sheet Cutting in Paper Manufacturing

Sheet cutting in paper manufacturing enhances production efficiency by enabling precise, customizable paper sizes that meet diverse industry requirements. This method reduces material waste compared to ream cutting, optimizing resource utilization and lowering overall costs. Additionally, sheet cutting facilitates smoother integration with automated packaging systems, improving workflow and minimizing handling errors.

Precision and Efficiency: Ream vs Sheet Cutting

Ream cutting delivers superior precision by reducing variability in paper size, ensuring consistent dimensions for high-quality printing and packaging applications. Sheet cutting offers greater efficiency in handling diverse paper sizes and quicker processing times, ideal for large-volume operations requiring fast turnaround. Balancing precision and efficiency depends on the specific production needs, with ream cutting favored for exact measurements and sheet cutting preferred for speed and versatility.

Cost Implications of Ream Cutting vs Sheet Cutting

Ream cutting often reduces material waste by optimizing cut patterns, leading to lower raw material expenses compared to sheet cutting. Sheet cutting typically involves higher labor and machine setup costs, increasing overall production expenses. Evaluating the volume and precision requirements can determine whether ream cutting offers a more cost-effective solution than sheet cutting for paper processing.

Impact on Paper Quality: Comparing Cutting Methods

Ream cutting typically ensures more consistent edge quality and reduces fiber damage compared to sheet cutting, which can cause micro-tears and uneven edges impacting print clarity. Precision in ream cutting minimizes paper dust and enhances the structural integrity of paper sheets, making it ideal for high-quality printing. Sheet cutting, while faster for smaller batches, often compromises the uniformity and smoothness crucial for professional-grade paper products.

Best Applications for Ream Cutting

Ream cutting is ideal for applications requiring large volumes of uniform paper sizes, such as commercial printing and bulk packaging industries. It optimizes efficiency in high-speed cutter environments by minimizing setup times and material waste compared to sheet cutting. This method ensures consistent paper quality and is best suited for mass production where standard dimensions are essential.

Ideal Uses for Sheet Cutting in Paper Production

Sheet cutting in paper production is ideal for creating precise, uniform sizes tailored to specific applications such as printing, packaging, and stationery manufacturing. This method optimizes material usage by minimizing waste and supports high-volume output with consistent quality. It excels in producing standardized sheets that facilitate automated processing and efficient distribution.

Choosing the Right Cutting Method for Your Paper Needs

Ream cutting is ideal for bulk processing large quantities of paper, offering efficiency and uniformity, while sheet cutting provides precision for custom sizes and specific project requirements. Selecting the right cutting method depends on the volume, paper type, and the intended use, ensuring minimal waste and optimal quality. Understanding the differences between ream cutting and sheet cutting helps businesses and individuals maximize resource utilization and print accuracy.

Ream Cutting vs Sheet Cutting Infographic

materialdif.com

materialdif.com