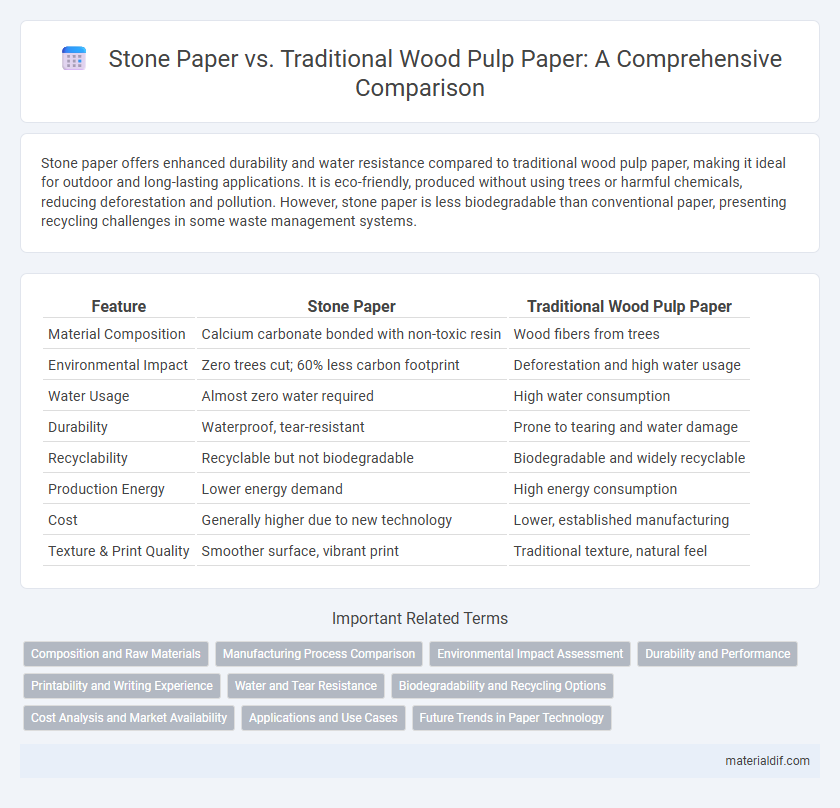

Stone paper offers enhanced durability and water resistance compared to traditional wood pulp paper, making it ideal for outdoor and long-lasting applications. It is eco-friendly, produced without using trees or harmful chemicals, reducing deforestation and pollution. However, stone paper is less biodegradable than conventional paper, presenting recycling challenges in some waste management systems.

Table of Comparison

| Feature | Stone Paper | Traditional Wood Pulp Paper |

|---|---|---|

| Material Composition | Calcium carbonate bonded with non-toxic resin | Wood fibers from trees |

| Environmental Impact | Zero trees cut; 60% less carbon footprint | Deforestation and high water usage |

| Water Usage | Almost zero water required | High water consumption |

| Durability | Waterproof, tear-resistant | Prone to tearing and water damage |

| Recyclability | Recyclable but not biodegradable | Biodegradable and widely recyclable |

| Production Energy | Lower energy demand | High energy consumption |

| Cost | Generally higher due to new technology | Lower, established manufacturing |

| Texture & Print Quality | Smoother surface, vibrant print | Traditional texture, natural feel |

Composition and Raw Materials

Stone paper is made primarily from calcium carbonate, which accounts for about 80% of its composition, combined with a small amount of non-toxic resin as a binder, eliminating the need for wood pulp. In contrast, traditional paper relies heavily on cellulose fibers extracted from wood pulp, sourced from trees, requiring extensive water and chemical treatments during processing. The mineral base of stone paper results in a more water-resistant and tear-proof product, while traditional wood pulp paper remains more biodegradable but demands significant natural resource consumption.

Manufacturing Process Comparison

Stone paper manufacturing utilizes calcium carbonate bonded with non-toxic resin through a dry pressing process, eliminating the need for water, bleaching, and acidic chemicals typical in traditional wood pulp paper production. Traditional paper relies heavily on pulping wood fibers using water-intensive mechanical or chemical processes, followed by bleaching with chlorine or chlorine compounds that contribute to environmental pollution. The stone paper process significantly reduces energy consumption and chemical waste in comparison to the laborious and resource-heavy methods involved in wood pulp paper manufacturing.

Environmental Impact Assessment

Stone paper, made primarily from calcium carbonate, significantly reduces the need for water and eliminates the use of harmful chemicals found in traditional wood pulp paper production. Unlike conventional paper, stone paper is fully recyclable, generates less carbon dioxide during manufacturing, and does not require deforestation, thereby preserving biodiversity and reducing habitat loss. Its non-toxic composition and biodegradability contribute to a lower environmental footprint compared to wood pulp paper, which involves extensive pulping processes and large-scale deforestation.

Durability and Performance

Stone paper, made from calcium carbonate bonded with non-toxic resin, exhibits superior durability compared to traditional wood pulp paper, resisting water, tear, and stretching more effectively. Its performance in various environmental conditions enhances longevity, making it ideal for packaging, printing, and outdoor applications where moisture and wear are concerns. Unlike wood pulp paper, stone paper's synthetic composition eliminates the need for coatings or lamination, improving its strength and resilience without added chemicals.

Printability and Writing Experience

Stone paper offers superior printability with its smooth, non-porous surface that prevents ink bleed and ensures vibrant color reproduction, making it ideal for high-quality prints and detailed graphics. Traditional wood pulp paper, while more porous, provides a textured surface that enhances the tactile writing experience with most ink types, though it may cause slight feathering or smudging. Both materials cater to different needs: stone paper excels in sharp, clean printing, whereas wood pulp paper remains preferred for traditional pen-and-pencil use.

Water and Tear Resistance

Stone paper exhibits superior water resistance compared to traditional wood pulp paper, as it is made from calcium carbonate bonded with non-toxic resin, preventing water absorption and warping. Tear resistance is also enhanced in stone paper due to its composite structure, making it more durable and less prone to ripping under stress. These properties make stone paper an ideal choice for applications requiring longevity and resilience in humid or physically demanding environments.

Biodegradability and Recycling Options

Stone paper, made primarily from calcium carbonate bonded with non-toxic resin, offers limited biodegradability compared to traditional wood pulp paper, which decomposes naturally due to its cellulose content. Recycling options for stone paper are less established, often requiring specialized facilities to separate the resin, whereas wood pulp paper benefits from widespread recycling infrastructure and processes. Environmental impact assessments highlight wood pulp paper's greater compatibility with existing biodegradation and recycling systems, despite stone paper's resistance to water and tearing.

Cost Analysis and Market Availability

Stone paper offers a competitive cost advantage over traditional wood pulp paper due to lower raw material expenses and reduced energy consumption during production, making it economically appealing for eco-conscious consumers. Market availability of stone paper is expanding steadily as manufacturers increase capacity and retailers respond to rising demand for sustainable alternatives. Traditional wood pulp paper remains more widely available, supported by established supply chains and lower initial costs, but rising environmental regulations are driving a gradual shift toward stone paper products.

Applications and Use Cases

Stone paper excels in waterproof packaging, eco-friendly stationery, and durable labels due to its tear-resistant and moisture-proof properties. Traditional wood pulp paper remains dominant for printing, publishing, and archival documents because of its texture and ability to absorb inks effectively. Industries targeting sustainability favor stone paper as a plastic alternative, while conventional paper is preferred for office and educational materials.

Future Trends in Paper Technology

Stone paper, made from calcium carbonate bonded with non-toxic resin, offers significant environmental advantages over traditional wood pulp paper by reducing deforestation and water consumption. Future trends in paper technology emphasize increased adoption of sustainable materials like stone paper, enhanced recyclability, and innovations in biodegradable coatings to improve durability without harming ecosystems. Advances in sensor-integrated and smart paper technologies also point toward multifunctional applications, merging sustainability with digital interactivity.

Stone Paper vs Traditional Wood Pulp Paper Infographic

materialdif.com

materialdif.com