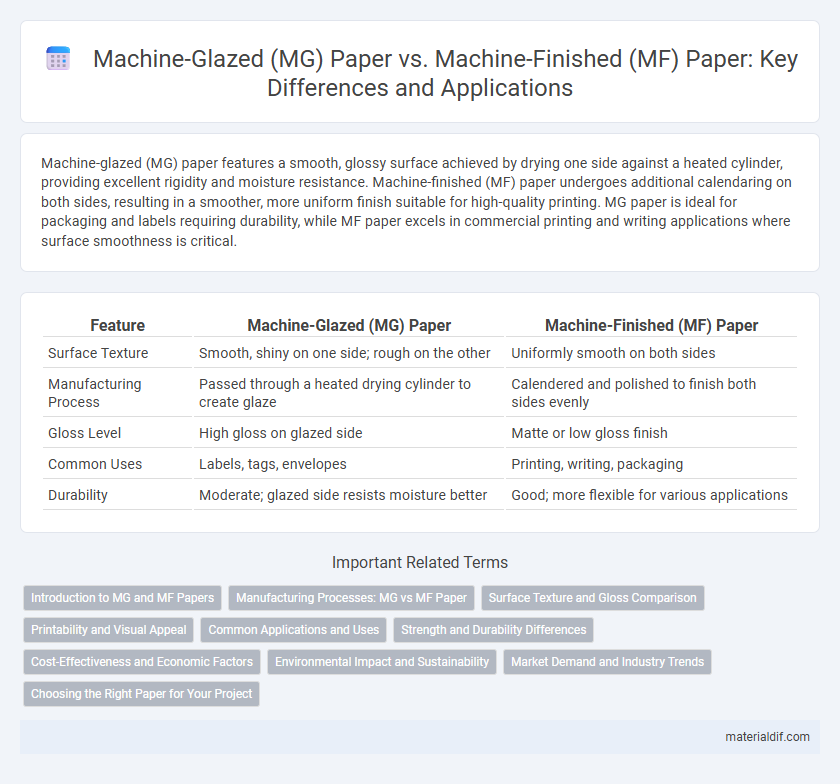

Machine-glazed (MG) paper features a smooth, glossy surface achieved by drying one side against a heated cylinder, providing excellent rigidity and moisture resistance. Machine-finished (MF) paper undergoes additional calendaring on both sides, resulting in a smoother, more uniform finish suitable for high-quality printing. MG paper is ideal for packaging and labels requiring durability, while MF paper excels in commercial printing and writing applications where surface smoothness is critical.

Table of Comparison

| Feature | Machine-Glazed (MG) Paper | Machine-Finished (MF) Paper |

|---|---|---|

| Surface Texture | Smooth, shiny on one side; rough on the other | Uniformly smooth on both sides |

| Manufacturing Process | Passed through a heated drying cylinder to create glaze | Calendered and polished to finish both sides evenly |

| Gloss Level | High gloss on glazed side | Matte or low gloss finish |

| Common Uses | Labels, tags, envelopes | Printing, writing, packaging |

| Durability | Moderate; glazed side resists moisture better | Good; more flexible for various applications |

Introduction to MG and MF Papers

Machine-glazed (MG) paper features a high-gloss, smooth finish on one side achieved through contact with a heated cylinder during production, enhancing print quality and moisture resistance. Machine-finished (MF) paper offers a matte or semi-matte surface on both sides, created by calendering with softer pressure, resulting in improved opacity and bulk. MG paper is commonly used for labels and packaging, while MF paper suits applications requiring better printability and a more tactile feel.

Manufacturing Processes: MG vs MF Paper

Machine-glazed (MG) paper is produced by drying the paper web against a highly polished, heated cylinder, resulting in one side with a glossy, smooth surface and the opposite side rougher. Machine-finished (MF) paper undergoes additional processing through calendar stacks after drying, which smooths both sides to create a uniform finish suitable for writing and printing. The key manufacturing difference lies in the drying stage for MG paper versus the post-drying finishing for MF paper, impacting surface texture and reflectivity.

Surface Texture and Gloss Comparison

Machine-glazed (MG) paper features a smooth, glossy surface due to the high-speed polishing against a heated cylinder, resulting in a distinct high-gloss finish ideal for premium printing. Machine-finished (MF) paper undergoes calendering processes that produce a softer, less reflective surface with moderate gloss, favored for applications requiring consistent ink absorption. The difference in surface texture and gloss between MG and MF papers profoundly impacts print quality, with MG paper offering sharper image definition and MF paper providing superior ink holdout.

Printability and Visual Appeal

Machine-glazed (MG) paper features a smooth, shiny finish on one side created by drying the paper against a polished cylinder, enhancing print sharpness and color vibrancy primarily on the glazed surface. In contrast, Machine-finished (MF) paper offers a uniform texture on both sides, providing consistent print quality with moderate gloss that supports versatile applications. MG paper excels in high-contrast, high-detail printing where visual appeal is crucial, while MF paper is preferred for balanced printability and tactile smoothness across the entire sheet.

Common Applications and Uses

Machine-glazed (MG) paper, characterized by its glossy, smooth finish on one side and rough texture on the other, is commonly used in packaging, labels, and book covers where durability and water resistance are essential. Machine-finished (MF) paper features a more uniform surface on both sides, making it suitable for printing, writing, and general office use due to its balanced finish and moderate brightness. Industries choose MG paper for applications requiring strength and moisture barrier properties, while MF paper is preferred for everyday documents, brochures, and flyers.

Strength and Durability Differences

Machine-glazed (MG) paper exhibits a smoother, denser surface on one side due to the glazing process, which significantly enhances its strength and resistance to moisture compared to machine-finished (MF) paper. MG paper's higher tensile strength and improved tear resistance make it ideal for packaging applications requiring durability and protection. In contrast, MF paper offers a more uniform surface on both sides but generally lacks the reinforced strength properties present in MG paper, resulting in lower durability under mechanical stress.

Cost-Effectiveness and Economic Factors

Machine-glazed (MG) paper generally offers higher gloss and stiffness due to the finishing process, making it suitable for packaging applications where durability and appearance are critical, while often being more cost-effective than premium coated papers. Machine-finished (MF) paper provides a smoother and more uniform surface for printing, which may involve higher production costs but enhances print quality for commercial use. Evaluating the total cost-effectiveness involves balancing MG paper's lower manufacturing expenses and durability against MF paper's superior printability and finish quality, impacting budget decisions in bulk procurement and specific end-use requirements.

Environmental Impact and Sustainability

Machine-glazed (MG) paper offers greater environmental benefits due to its single-sided glazing process, which consumes less energy and reduces chemical usage compared to machine-finished (MF) paper that undergoes double-sided finishing. MG paper typically requires fewer water resources and produces less wastewater, enhancing its sustainability profile in industrial applications. Choosing MG paper supports lower carbon emissions and contributes to sustainable forestry practices by optimizing resource efficiency throughout production.

Market Demand and Industry Trends

Machine-glazed (MG) paper exhibits growing market demand due to its distinct high-gloss finish and superior water resistance, making it ideal for packaging and label applications. Machine-finished (MF) paper remains widely used in printing and writing sectors because of its smoother surface and versatility. Industry trends show a shift towards eco-friendly coatings and sustainable sourcing for both MG and MF papers, driven by increasing environmental regulations and consumer preferences.

Choosing the Right Paper for Your Project

Machine-glazed (MG) paper features a high-gloss finish on one side, ideal for packaging and labels requiring sharp image clarity and moisture resistance. Machine-finished (MF) paper has a uniform matte surface on both sides, offering better printability for text-heavy documents and general office use. Selecting MG or MF paper depends on your project's need for visual impact and durability versus ease of writing and double-sided printing quality.

Machine-glazed (MG) paper vs Machine-finished (MF) paper Infographic

materialdif.com

materialdif.com