Machine glazed paper features a smooth, glossy surface achieved by passing the paper over a heated, polished cylinder, enhancing its printability and brightness. Machine finished paper undergoes additional drying and calendering processes without glazing, resulting in a more matte and uniform finish ideal for writing and printing. Choosing between machine glazed and machine finished paper depends on the desired sheen and texture for the final application.

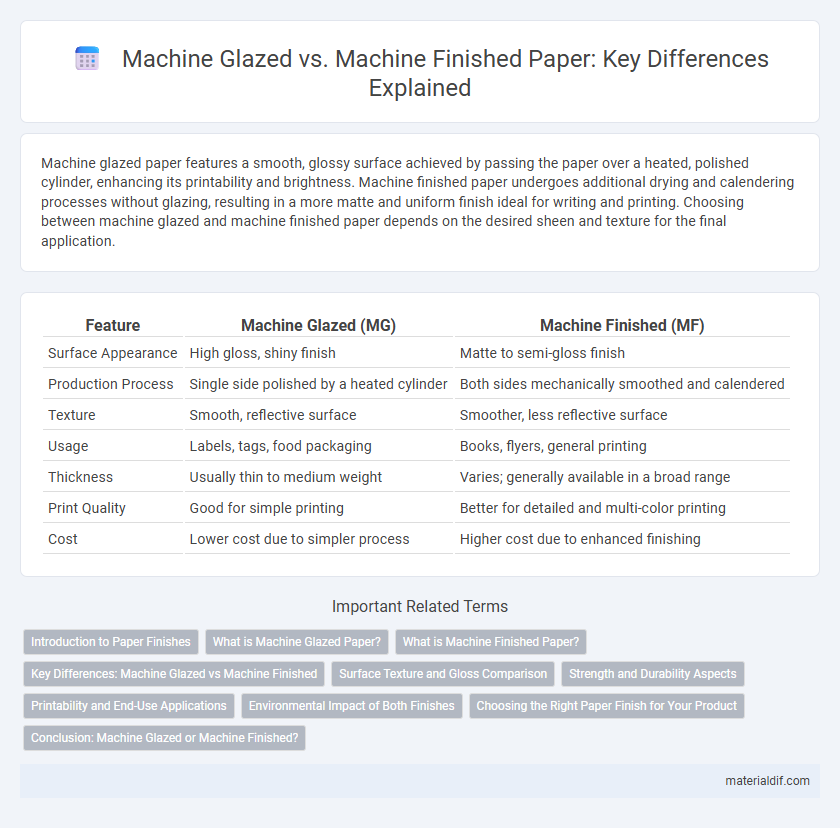

Table of Comparison

| Feature | Machine Glazed (MG) | Machine Finished (MF) |

|---|---|---|

| Surface Appearance | High gloss, shiny finish | Matte to semi-gloss finish |

| Production Process | Single side polished by a heated cylinder | Both sides mechanically smoothed and calendered |

| Texture | Smooth, reflective surface | Smoother, less reflective surface |

| Usage | Labels, tags, food packaging | Books, flyers, general printing |

| Thickness | Usually thin to medium weight | Varies; generally available in a broad range |

| Print Quality | Good for simple printing | Better for detailed and multi-color printing |

| Cost | Lower cost due to simpler process | Higher cost due to enhanced finishing |

Introduction to Paper Finishes

Machine glazed paper features a smooth, glossy surface achieved by pressing the paper against a heated, polished roller during production, enhancing brightness and print clarity. Machine finished paper undergoes additional mechanical treatments, such as calendering, to improve smoothness, density, and durability without significantly altering the paper's natural texture. These finishing processes influence ink absorption, print quality, and tactile feel, making them critical considerations for selecting paper in printing and packaging applications.

What is Machine Glazed Paper?

Machine glazed paper features a smooth, shiny surface created by pressing the paper web against a heated, polished metal roller during production, which imparts a high gloss finish on one side. This process enhances the paper's density, stiffness, and strength, making it ideal for applications such as packaging, labels, and book covers that require durability and a polished appearance. The uncoated backside of machine glazed paper contrasts with its glossy front, providing a balance of aesthetic appeal and practical functionality.

What is Machine Finished Paper?

Machine finished paper refers to paper that undergoes a drying and smoothing process directly on the papermaking machine, resulting in a smooth but slightly textured surface. This method enhances brightness, improves printing properties, and provides moderate stiffness without applying extra coatings or calendering. It contrasts with machine glazed paper, which achieves a glossy, highly reflective finish through a glazed drying cylinder.

Key Differences: Machine Glazed vs Machine Finished

Machine glazed paper features a highly reflective, glossy surface achieved by pressing the paper against a polished roller during the drying process, enhancing brightness and smoothness primarily on one side. Machine finished paper undergoes additional surface treatments such as calendering or coating, resulting in a more uniform finish and improved printability on both sides. The key differences lie in surface texture, gloss level, and suitability for specific printing applications, with machine glazed paper favored for packaging and labels, while machine finished paper is preferred for high-quality printing and writing purposes.

Surface Texture and Gloss Comparison

Machine glazed paper features a smooth, shiny surface achieved by pressing the paper against a heated cylinder, resulting in higher gloss and a reflective finish ideal for packaging and labels. Machine finished paper undergoes calendering through rollers to create a uniform surface texture with moderate gloss, offering better printability and writing quality. Comparing both, machine glazed paper excels in surface gloss and smoothness, while machine finished paper balances surface texture with versatile functional performance.

Strength and Durability Aspects

Machine glazed paper features a shiny, smooth surface achieved by pressing the paper against a heated cylinder, resulting in moderate strength but enhanced gloss and printability. Machine finished paper undergoes additional mechanical treatments such as calendering, improving fiber bonding that significantly increases durability and tensile strength. The choice between machine glazed and machine finished papers should consider the balance between surface smoothness for printing quality and the structural toughness required for end-use applications.

Printability and End-Use Applications

Machine glazed paper features a high-gloss, smooth surface, enhancing printability for monochrome and spot-color printing, making it ideal for labels, tags, and packaging that require sharp, vibrant images. Machine finished paper undergoes additional calendering or coating processes, resulting in a more uniform surface texture suited for high-quality multi-color printing and detailed graphics, perfect for brochures, flyers, and premium packaging applications. The choice between machine glazed and machine finished paper depends on the desired print quality and end-use functionality, with machine glazed emphasizing gloss and opacity, while machine finished prioritizes versatility and finer print detail.

Environmental Impact of Both Finishes

Machine glazed paper produces a shiny, smooth surface by pressing the paper against a polished cylinder, consuming less energy and generating fewer emissions compared to the machine finished process. Machine finished paper involves calendering or coating steps that require more water, chemicals, and higher energy inputs, leading to increased environmental impact through greater resource use and waste production. Life cycle assessments show machine glazed finishes typically result in lower carbon footprints and reduced chemical runoff, making it more eco-friendly for large-scale paper production.

Choosing the Right Paper Finish for Your Product

Machine glazed paper features a high-gloss surface created by pressing the paper against a polished cylinder, offering a smooth, reflective finish ideal for packaging and labels requiring vibrant visuals. Machine finished paper undergoes calendering with multiple rollers, providing varied textures such as smooth, dull, or embossed, better suited for printing materials where tactile feel and opacity are important. Selecting the right paper finish depends on the desired aesthetic and functional qualities, balancing glossiness, print clarity, and application needs to enhance product presentation.

Conclusion: Machine Glazed or Machine Finished?

Machine glazed paper offers a smooth, shiny surface ideal for high-quality printing and packaging, while machine finished paper provides a more versatile, matte finish suitable for writing and general use. The choice depends on the desired aesthetic and functional properties, with machine glazed preferred for visual appeal and machine finished for broader applications. Evaluating print requirements and end-use scenarios helps determine the optimal paper finish.

Machine Glazed vs Machine Finished Infographic

materialdif.com

materialdif.com