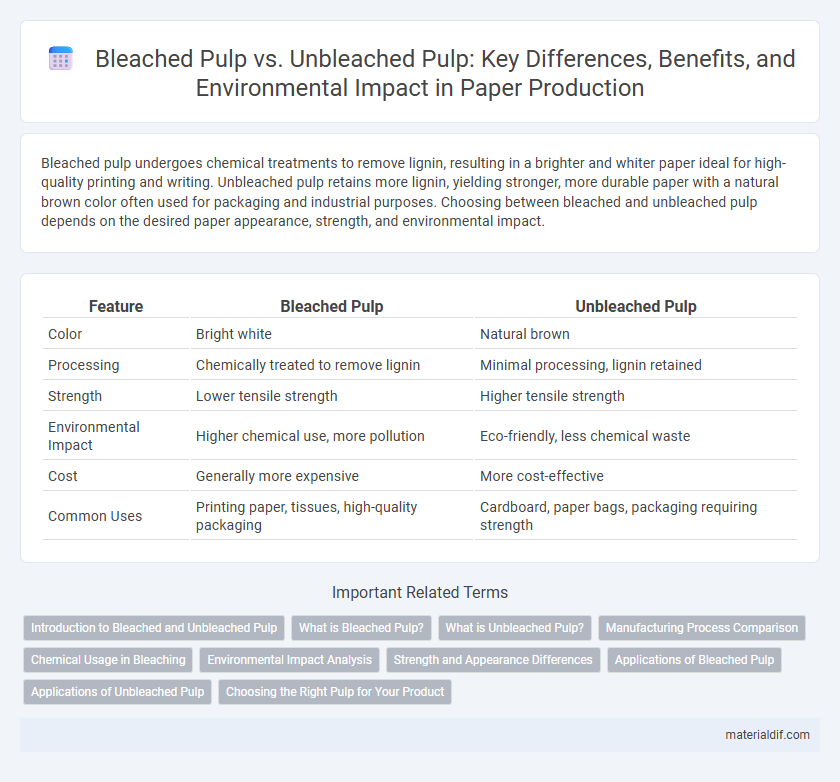

Bleached pulp undergoes chemical treatments to remove lignin, resulting in a brighter and whiter paper ideal for high-quality printing and writing. Unbleached pulp retains more lignin, yielding stronger, more durable paper with a natural brown color often used for packaging and industrial purposes. Choosing between bleached and unbleached pulp depends on the desired paper appearance, strength, and environmental impact.

Table of Comparison

| Feature | Bleached Pulp | Unbleached Pulp |

|---|---|---|

| Color | Bright white | Natural brown |

| Processing | Chemically treated to remove lignin | Minimal processing, lignin retained |

| Strength | Lower tensile strength | Higher tensile strength |

| Environmental Impact | Higher chemical use, more pollution | Eco-friendly, less chemical waste |

| Cost | Generally more expensive | More cost-effective |

| Common Uses | Printing paper, tissues, high-quality packaging | Cardboard, paper bags, packaging requiring strength |

Introduction to Bleached and Unbleached Pulp

Bleached pulp undergoes a chemical whitening process to remove lignin, resulting in brighter, more uniform paper ideal for printing and writing applications. Unbleached pulp retains its natural brown color and higher lignin content, providing greater strength and durability for packaging and industrial uses. The choice between bleached and unbleached pulp depends on the desired paper quality, environmental impact, and end-use requirements.

What is Bleached Pulp?

Bleached pulp is wood pulp that undergoes a chemical or mechanical process to remove lignin, resulting in a brighter, whiter appearance. This treatment enhances the pulp's purity and improves its suitability for high-quality paper products such as printing and writing papers. The bleaching process typically involves chlorine-based or oxygen-based compounds to achieve the desired whiteness.

What is Unbleached Pulp?

Unbleached pulp is a type of paper pulp that retains its natural brown color because it has not undergone the bleaching process to remove lignin and impurities. This pulp provides higher strength and durability compared to bleached pulp, making it ideal for packaging materials and industrial applications. Its production results in lower chemical usage and reduced environmental impact, appealing to eco-conscious manufacturers.

Manufacturing Process Comparison

Bleached pulp undergoes chemical treatments such as chlorine dioxide or hydrogen peroxide to remove lignin and impurities, resulting in a whiter and more refined product. Unbleached pulp retains its natural brown color as it skips the bleaching stage, preserving more lignin and requiring fewer chemicals during manufacturing. The bleaching process increases production costs and environmental impact compared to the simpler mechanical and chemical steps used in unbleached pulp manufacturing.

Chemical Usage in Bleaching

Bleached pulp undergoes extensive chemical treatment involving chlorine, chlorine dioxide, oxygen, hydrogen peroxide, and ozone to remove lignin and achieve high whiteness and brightness. Unbleached pulp retains most of its natural lignin with minimal chemical processing, resulting in a darker color but reduced chemical consumption. The bleaching process in bleached pulp significantly increases the environmental impact due to chemical waste and energy usage compared to unbleached pulp.

Environmental Impact Analysis

Bleached pulp undergoes chemical treatments involving chlorine or chlorine compounds, leading to the release of harmful dioxins and pollutants into water bodies, significantly impacting aquatic ecosystems. Unbleached pulp minimizes chemical use, resulting in lower water pollution and reduced ecological toxicity during production. Life cycle assessments reveal unbleached pulp offers a smaller carbon footprint and less environmental strain compared to bleached alternatives.

Strength and Appearance Differences

Bleached pulp offers a brighter, whiter appearance ideal for high-quality printing and packaging, while unbleached pulp retains its natural brown color with a coarser texture. In terms of strength, unbleached pulp generally exhibits higher tear and tensile strength due to the presence of lignin and fewer chemical treatments. Bleached pulp undergoes chemical processing that can weaken fiber structure but improves smoothness and uniformity, enhancing print clarity and visual appeal.

Applications of Bleached Pulp

Bleached pulp offers superior brightness and purity, making it ideal for high-quality printing papers, tissues, and specialty papers requiring a clean, white appearance. Its chemical treatment removes lignin, enhancing paper strength and durability for applications such as book publishing and premium packaging. Industries prioritize bleached pulp in products where aesthetic appeal and print clarity are critical.

Applications of Unbleached Pulp

Unbleached pulp is widely used in packaging materials, such as corrugated board and paper bags, due to its higher strength and natural brown color, which provides an eco-friendly appearance. Its durability and resistance to moisture make it ideal for industrial sacks, wrapping papers, and paperboard for food packaging. The absence of bleaching chemicals also aligns with sustainable practices, appealing to environmentally conscious manufacturers and consumers.

Choosing the Right Pulp for Your Product

Choosing the right pulp for your paper product depends on factors such as desired whiteness, strength, and environmental impact. Bleached pulp offers a bright, clean appearance ideal for high-quality printing and packaging, while unbleached pulp provides greater durability and a natural, rustic look suited for eco-friendly and industrial applications. Evaluating product requirements and sustainability goals ensures selecting the most suitable pulp enhances performance and brand appeal.

Bleached Pulp vs Unbleached Pulp Infographic

materialdif.com

materialdif.com