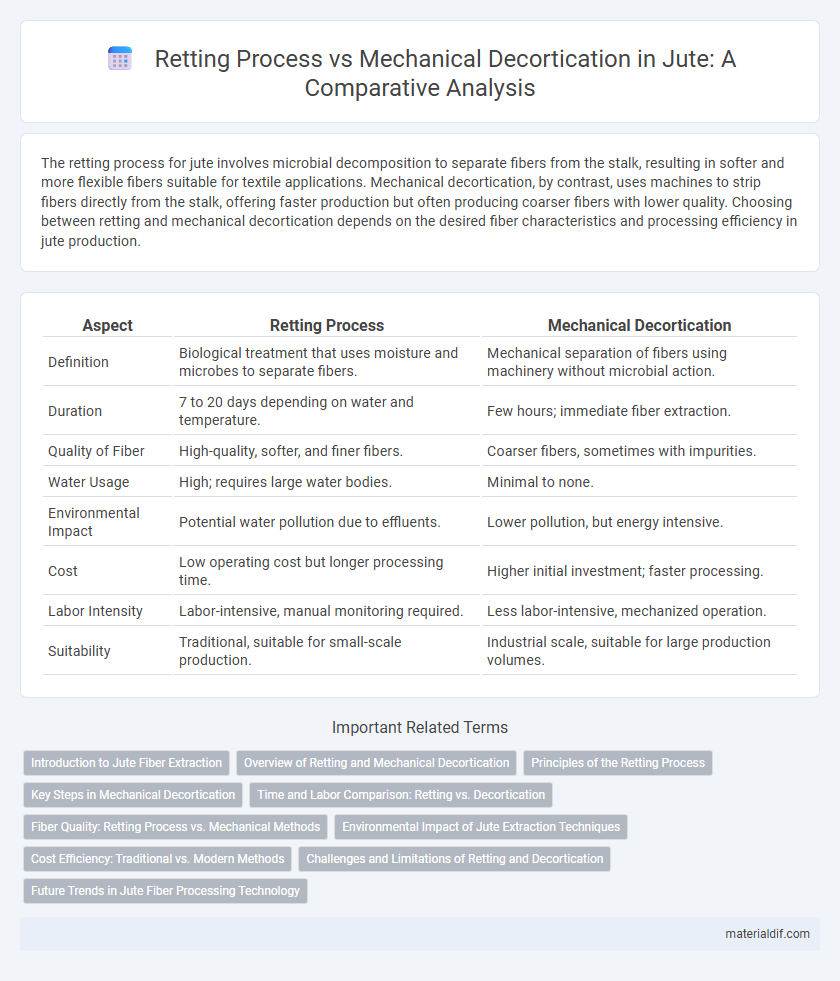

The retting process for jute involves microbial decomposition to separate fibers from the stalk, resulting in softer and more flexible fibers suitable for textile applications. Mechanical decortication, by contrast, uses machines to strip fibers directly from the stalk, offering faster production but often producing coarser fibers with lower quality. Choosing between retting and mechanical decortication depends on the desired fiber characteristics and processing efficiency in jute production.

Table of Comparison

| Aspect | Retting Process | Mechanical Decortication |

|---|---|---|

| Definition | Biological treatment that uses moisture and microbes to separate fibers. | Mechanical separation of fibers using machinery without microbial action. |

| Duration | 7 to 20 days depending on water and temperature. | Few hours; immediate fiber extraction. |

| Quality of Fiber | High-quality, softer, and finer fibers. | Coarser fibers, sometimes with impurities. |

| Water Usage | High; requires large water bodies. | Minimal to none. |

| Environmental Impact | Potential water pollution due to effluents. | Lower pollution, but energy intensive. |

| Cost | Low operating cost but longer processing time. | Higher initial investment; faster processing. |

| Labor Intensity | Labor-intensive, manual monitoring required. | Less labor-intensive, mechanized operation. |

| Suitability | Traditional, suitable for small-scale production. | Industrial scale, suitable for large production volumes. |

Introduction to Jute Fiber Extraction

Jute fiber extraction involves two primary methods: retting and mechanical decortication, each with distinct processes and efficiencies. Retting uses microbial action to separate fibers by breaking down pectins, resulting in high-quality fibers but requiring extended time and water resources. Mechanical decortication applies physical force to strip fibers from stalks rapidly, producing lower-quality fibers but offering faster processing suitable for industrial-scale jute production.

Overview of Retting and Mechanical Decortication

Retting is a traditional biological process involving the microbial breakdown of pectin to separate jute fibers from the stalk, enhancing fiber quality through controlled water immersion. Mechanical decortication uses machinery to crush and scrape the stalk, enabling faster fiber extraction but often resulting in coarser fibers with higher impurities. Understanding the balance between retting's fiber refinement and mechanical decortication's efficiency is crucial for optimizing jute fiber production.

Principles of the Retting Process

The retting process involves natural microbial action to break down the pectin binding fibers in jute stalks, facilitating fiber separation through controlled water submersion or dew exposure. Key principles include maintaining optimal temperature, moisture, and time to enhance enzymatic activity for efficient fiber loosening without damaging fiber strength. This biological decortication contrasts with mechanical methods that physically strip fibers, often resulting in lower fiber quality and higher energy consumption.

Key Steps in Mechanical Decortication

Mechanical decortication involves several key steps including harvesting, drying, and feeding the jute stalks into a decorticator machine that crushes and strips the outer bark from the fiber. The process includes cleaning, separating fibers from the woody core, and grading the fibers based on quality. This method offers faster fiber extraction compared to traditional retting, reducing water use and environmental impact.

Time and Labor Comparison: Retting vs. Decortication

Retting of jute typically requires 20 to 30 days of water submersion, demanding significant manual labor for monitoring and handling fiber extraction. Mechanical decortication, on the other hand, reduces processing time to just a few hours with the use of machines but requires skilled operators and higher initial investment. While retting is labor-intensive and lengthy, decortication offers faster output but depends on mechanized infrastructure.

Fiber Quality: Retting Process vs. Mechanical Methods

The retting process enhances jute fiber quality by naturally separating fibers through microbial action, resulting in stronger, softer, and finer fiber compared to mechanical decortication. Mechanical methods often produce coarser fibers with higher impurities and lower tensile strength due to the physical force applied during extraction. Retting promotes better fiber flexibility and uniformity, making it preferable for high-quality jute products.

Environmental Impact of Jute Extraction Techniques

The retting process for jute extraction involves microbial degradation of the stalks in water, leading to significant water pollution and high biochemical oxygen demand (BOD) in local water bodies. Mechanical decortication, by contrast, is a dry process that reduces water contamination but often results in higher energy consumption and increased dust emissions. Evaluating the environmental impact of these techniques reveals that retting poses greater risks to aquatic ecosystems, while mechanical decortication demands sustainable energy management to minimize its ecological footprint.

Cost Efficiency: Traditional vs. Modern Methods

The retting process for jute extraction, relying on natural microbial action, incurs lower initial costs but demands extended time and labor, impacting overall cost efficiency. Mechanical decortication, a modern alternative, requires higher upfront investment in machinery yet accelerates fiber separation, reducing labor expenses and enhancing throughput. Evaluating cost efficiency balances traditional low-tech affordability against mechanized processing's potential for scalability and time-saving benefits in jute fiber production.

Challenges and Limitations of Retting and Decortication

Retting process faces challenges such as time consumption, dependency on favorable climatic conditions, and potential water pollution due to microbial activity. Mechanical decortication encounters limitations including high energy consumption, fiber damage, and lower fiber quality compared to retting. Both methods struggle with optimizing fiber yield and maintaining environmental sustainability.

Future Trends in Jute Fiber Processing Technology

Emerging trends in jute fiber processing emphasize advancements in enzymatic retting techniques, which significantly reduce water consumption and environmental impact compared to traditional water retting methods. Mechanical decortication is evolving through automation and precision engineering, enhancing fiber quality and extraction efficiency while minimizing fiber damage. Integration of smart sensors and AI-driven process controls is set to revolutionize both retting and decortication, promoting sustainable production and higher value jute fiber applications.

Retting Process vs Mechanical Decortication Infographic

materialdif.com

materialdif.com