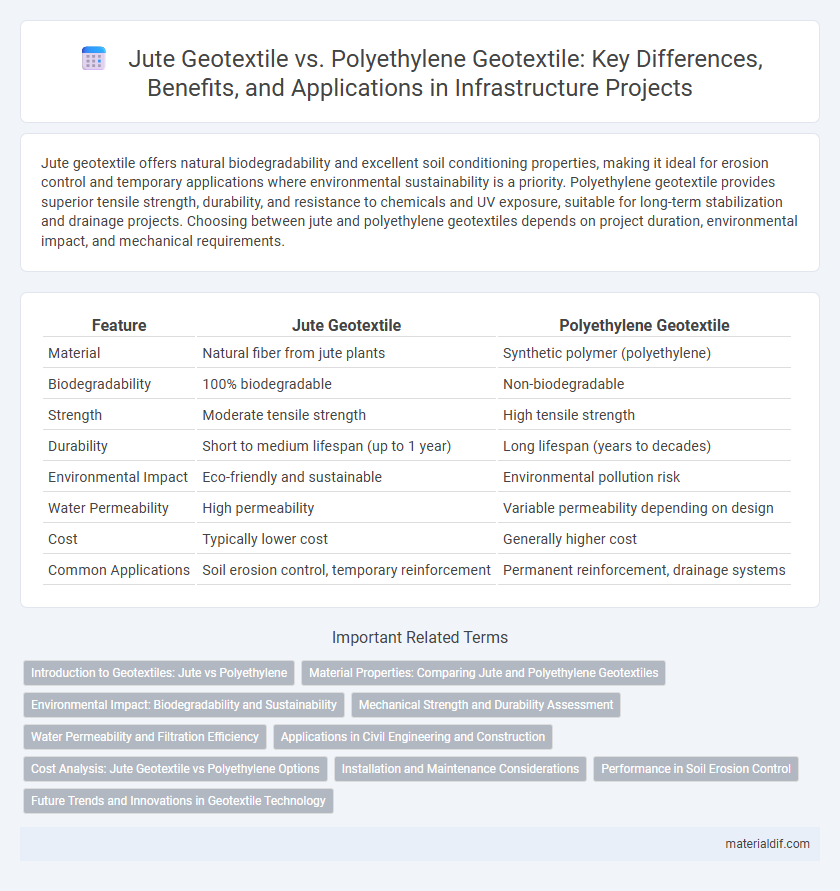

Jute geotextile offers natural biodegradability and excellent soil conditioning properties, making it ideal for erosion control and temporary applications where environmental sustainability is a priority. Polyethylene geotextile provides superior tensile strength, durability, and resistance to chemicals and UV exposure, suitable for long-term stabilization and drainage projects. Choosing between jute and polyethylene geotextiles depends on project duration, environmental impact, and mechanical requirements.

Table of Comparison

| Feature | Jute Geotextile | Polyethylene Geotextile |

|---|---|---|

| Material | Natural fiber from jute plants | Synthetic polymer (polyethylene) |

| Biodegradability | 100% biodegradable | Non-biodegradable |

| Strength | Moderate tensile strength | High tensile strength |

| Durability | Short to medium lifespan (up to 1 year) | Long lifespan (years to decades) |

| Environmental Impact | Eco-friendly and sustainable | Environmental pollution risk |

| Water Permeability | High permeability | Variable permeability depending on design |

| Cost | Typically lower cost | Generally higher cost |

| Common Applications | Soil erosion control, temporary reinforcement | Permanent reinforcement, drainage systems |

Introduction to Geotextiles: Jute vs Polyethylene

Jute geotextiles, derived from natural fibers, offer excellent biodegradability and environmental sustainability compared to synthetic polyethylene geotextiles, which provide higher tensile strength and longer durability. Jute's porous structure allows superior water permeability and soil aeration, making it ideal for erosion control and temporary reinforcement, whereas polyethylene geotextiles are preferred for permanent applications requiring resistance to chemicals and UV exposure. The choice between jute and polyethylene geotextiles depends on project longevity, ecological impact, and mechanical performance requirements.

Material Properties: Comparing Jute and Polyethylene Geotextiles

Jute geotextiles are biodegradable, breathable, and have high moisture retention, making them ideal for erosion control in environmentally sensitive areas. Polyethylene geotextiles offer superior tensile strength, UV resistance, and durability for long-term soil stabilization and drainage applications. Each material's distinct properties determine their suitability, with jute favored for eco-friendly projects and polyethylene for heavy-duty engineering needs.

Environmental Impact: Biodegradability and Sustainability

Jute geotextiles offer superior environmental benefits due to their biodegradability and renewable nature, decomposing naturally without leaving harmful residues. Polyethylene geotextiles, derived from non-renewable fossil fuels, persist in ecosystems long after use, contributing to plastic pollution. The sustainable production and disposal processes of jute significantly reduce carbon footprint compared to synthetic alternatives.

Mechanical Strength and Durability Assessment

Jute geotextiles exhibit moderate mechanical strength with tensile strengths typically ranging between 2-5 kN/m, suitable for temporary erosion control but limited in load-bearing applications. Polyethylene geotextiles demonstrate superior mechanical strength, often exceeding 20 kN/m tensile strength, providing excellent durability and resistance to UV degradation and chemical exposure. Durability assessments show jute's biodegradability limits its lifespan to 1-2 years under environmental exposure, while polyethylene geotextiles maintain structural integrity for several decades, making them ideal for long-term reinforcement and stabilization projects.

Water Permeability and Filtration Efficiency

Jute geotextiles exhibit superior water permeability due to their natural fiber structure, allowing efficient drainage while maintaining soil stability. Polyethylene geotextiles typically have lower permeability but offer higher filtration efficiency by effectively preventing fine particles from passing through. The biodegradable nature of jute also enhances its environmental sustainability compared to synthetic polyethylene alternatives.

Applications in Civil Engineering and Construction

Jute geotextiles offer superior biodegradability and natural filtration, making them ideal for soil erosion control, slope stabilization, and temporary landscaping in civil engineering. Polyethylene geotextiles provide high tensile strength, chemical resistance, and durability, suitable for permanent reinforcement, drainage systems, and separation layers in road construction and earthworks. Both materials are widely used, but jute's eco-friendliness suits environmentally sensitive projects, while polyethylene excels in long-term infrastructure applications.

Cost Analysis: Jute Geotextile vs Polyethylene Options

Jute geotextiles offer a cost-effective solution with lower initial investment costs compared to polyethylene geotextiles, making them ideal for budget-sensitive projects. Polyethylene options, while more expensive upfront, provide longer durability and resistance to UV degradation, potentially reducing long-term replacement costs. Evaluating life-cycle expenses reveals jute as an economical choice for temporary applications, whereas polyethylene suits permanent installations requiring extended performance.

Installation and Maintenance Considerations

Jute geotextile offers natural biodegradability and easier handling during installation due to its flexibility and lightweight structure, making it ideal for erosion control in softer soils. Polyethylene geotextile requires precise cutting and fastening techniques to ensure durability but offers higher resistance to chemicals and UV exposure, reducing maintenance frequency. Maintenance of jute geotextiles involves monitoring for biodegradation and potential replacement, whereas polyethylene geotextiles demand regular inspections for physical damage and cleaning to maintain permeability.

Performance in Soil Erosion Control

Jute geotextiles exhibit superior biodegradability and natural water permeability, promoting soil stabilization and preventing erosion through enhanced root growth support. Polyethylene geotextiles offer higher tensile strength and durability, providing long-term erosion control in harsh environmental conditions. The choice depends on project lifespan requirements and environmental impact considerations, with jute favored for eco-friendly solutions and polyethylene for robust, prolonged protection.

Future Trends and Innovations in Geotextile Technology

Jute geotextiles offer eco-friendly biodegradability and natural water permeability, driving increased adoption in sustainable construction and agricultural applications. Polyethylene geotextiles excel in durability and chemical resistance, with innovations focusing on enhanced UV stabilization and integration of smart sensing technologies for real-time soil monitoring. Future trends emphasize hybrid materials combining natural jute fibers with advanced polymers to optimize strength, longevity, and environmental compatibility in geotextile solutions.

Jute Geotextile vs Polyethylene Geotextile Infographic

materialdif.com

materialdif.com