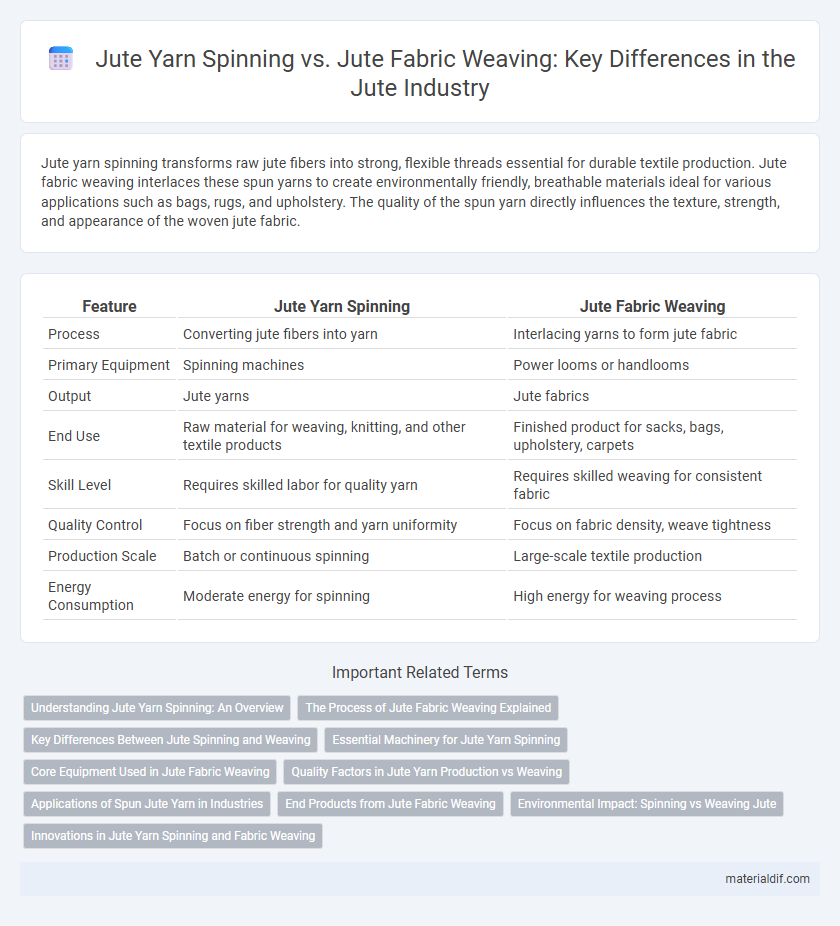

Jute yarn spinning transforms raw jute fibers into strong, flexible threads essential for durable textile production. Jute fabric weaving interlaces these spun yarns to create environmentally friendly, breathable materials ideal for various applications such as bags, rugs, and upholstery. The quality of the spun yarn directly influences the texture, strength, and appearance of the woven jute fabric.

Table of Comparison

| Feature | Jute Yarn Spinning | Jute Fabric Weaving |

|---|---|---|

| Process | Converting jute fibers into yarn | Interlacing yarns to form jute fabric |

| Primary Equipment | Spinning machines | Power looms or handlooms |

| Output | Jute yarns | Jute fabrics |

| End Use | Raw material for weaving, knitting, and other textile products | Finished product for sacks, bags, upholstery, carpets |

| Skill Level | Requires skilled labor for quality yarn | Requires skilled weaving for consistent fabric |

| Quality Control | Focus on fiber strength and yarn uniformity | Focus on fabric density, weave tightness |

| Production Scale | Batch or continuous spinning | Large-scale textile production |

| Energy Consumption | Moderate energy for spinning | High energy for weaving process |

Understanding Jute Yarn Spinning: An Overview

Jute yarn spinning involves the process of converting raw jute fibers into continuous yarns through carding, drawing, and spinning techniques that enhance fiber alignment and strength. This step is crucial for producing high-quality yarns with consistent thickness and durability, which serve as the foundational material for textile manufacturing. Understanding jute yarn spinning provides insight into how fiber properties influence the final fabric's texture, strength, and utility in applications like sacks, rugs, and upholstery.

The Process of Jute Fabric Weaving Explained

Jute fabric weaving involves interlacing warp and weft yarns on a loom to create durable textiles, where the tightly spun jute yarns are arranged longitudinally (warp) and transversely (weft) to form strong, coarse fabric. This process transforms the jute yarn, produced from the spinning stage that aligns and twists fibers, into various woven products like sacks, mats, and upholstery material. The weaving technique enhances fabric strength and texture, essential for jute's industrial and commercial applications.

Key Differences Between Jute Spinning and Weaving

Jute yarn spinning involves the process of converting raw jute fibers into yarn through carding, drawing, and spinning, focusing on fiber alignment and strength to produce consistent thread. Jute fabric weaving, on the other hand, interlaces these spun yarns on a loom to create fabric with specific patterns, density, and texture, emphasizing fabric structure and durability. The key differences lie in spinning transforming fibers into usable yarn, while weaving integrates yarns into finished textile products.

Essential Machinery for Jute Yarn Spinning

Essential machinery for jute yarn spinning includes carding machines, drawing frames, spinning frames, and ring frames, which collectively convert raw jute fibers into strong, uniform yarns. These machines ensure fiber alignment, tension control, and twisting necessary for producing consistent yarn quality. In contrast, jute fabric weaving employs looms to interlace spun yarns into fabric, emphasizing different mechanical processes.

Core Equipment Used in Jute Fabric Weaving

Core equipment used in jute fabric weaving includes power looms, handlooms, and dobby looms, which facilitate the interlacing of jute yarns to create durable fabrics. These weaving machines are equipped with essential parts like warp beams, heddles, shuttles, and reed, enabling precise tension control and uniform fabric texture. Advanced automatic looms enhance production speed and fabric quality, making them integral to modern jute fabric manufacturing processes.

Quality Factors in Jute Yarn Production vs Weaving

Jute yarn spinning quality depends on fiber length, uniformity, and twist tightness, directly influencing tensile strength and durability of the yarn. In contrast, jute fabric weaving quality is determined by loom type, weave density, and thread count, impacting fabric texture, strength, and resistance to wear. Superior yarn quality ensures consistent fabric performance, while advanced weaving techniques optimize breathability and flexibility in the final jute fabric.

Applications of Spun Jute Yarn in Industries

Spun jute yarn is extensively utilized in industries such as upholstery, carpet backing, and geotextiles due to its strength, durability, and eco-friendly properties. This yarn is preferred for producing ropes, bags, sacks, and industrial packaging materials, benefiting from its high tensile strength and biodegradability. In contrast to jute fabric weaving, which focuses on creating finished textiles, jute yarn spinning primarily supports industrial applications that require raw or semi-finished jute products.

End Products from Jute Fabric Weaving

Jute fabric weaving transforms jute yarn into durable textiles prominently used in sacks, bags, carpet backing, and upholstery materials, offering high tensile strength and biodegradability. The woven jute fabrics provide a versatile base for producing eco-friendly products such as curtains, mats, and insulation materials, leveraging the natural breathability and moisture absorption of jute fibers. These end products from jute fabric weaving fulfill market demands in agriculture, packaging, home furnishings, and sustainable fashion sectors.

Environmental Impact: Spinning vs Weaving Jute

Jute yarn spinning primarily consumes less water and energy compared to jute fabric weaving, making it a more eco-friendly process in fiber preparation. In contrast, jute fabric weaving involves higher electricity usage due to the machinery required for interlacing yarns into textiles. Overall, spinning jute yarn contributes to reduced carbon emissions and resource depletion relative to the more energy-intensive weaving stage.

Innovations in Jute Yarn Spinning and Fabric Weaving

Innovations in jute yarn spinning have significantly improved fiber strength and uniformity through advanced ring spinning and open-end spinning technologies, enhancing yarn quality for diverse applications. In jute fabric weaving, developments such as air-jet looms and computerized jacquard machines have increased production efficiency and enabled intricate designs with reduced material waste. These technological advancements collectively contribute to higher durability, better texture, and expanded uses in eco-friendly textiles and composites.

Jute Yarn Spinning vs Jute Fabric Weaving Infographic

materialdif.com

materialdif.com