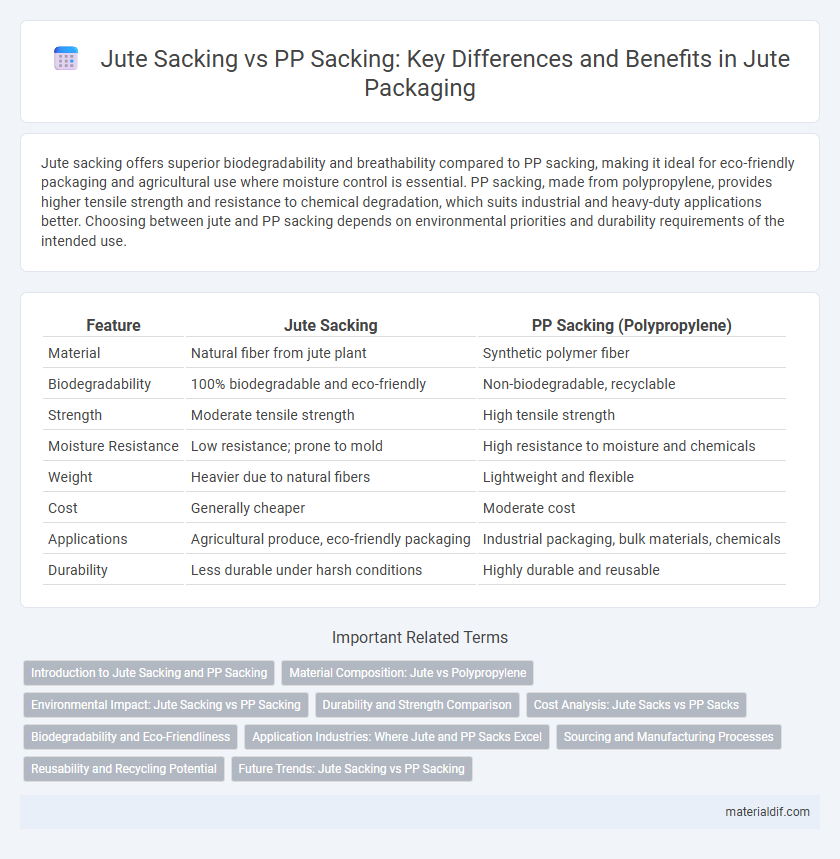

Jute sacking offers superior biodegradability and breathability compared to PP sacking, making it ideal for eco-friendly packaging and agricultural use where moisture control is essential. PP sacking, made from polypropylene, provides higher tensile strength and resistance to chemical degradation, which suits industrial and heavy-duty applications better. Choosing between jute and PP sacking depends on environmental priorities and durability requirements of the intended use.

Table of Comparison

| Feature | Jute Sacking | PP Sacking (Polypropylene) |

|---|---|---|

| Material | Natural fiber from jute plant | Synthetic polymer fiber |

| Biodegradability | 100% biodegradable and eco-friendly | Non-biodegradable, recyclable |

| Strength | Moderate tensile strength | High tensile strength |

| Moisture Resistance | Low resistance; prone to mold | High resistance to moisture and chemicals |

| Weight | Heavier due to natural fibers | Lightweight and flexible |

| Cost | Generally cheaper | Moderate cost |

| Applications | Agricultural produce, eco-friendly packaging | Industrial packaging, bulk materials, chemicals |

| Durability | Less durable under harsh conditions | Highly durable and reusable |

Introduction to Jute Sacking and PP Sacking

Jute sacking, made from natural fibers derived from the jute plant, is biodegradable, breathable, and environmentally friendly, commonly used for packaging agricultural products like potatoes and coffee beans. PP (polypropylene) sacking, crafted from synthetic polymer fibers, offers superior strength, water resistance, and durability, making it ideal for heavy-duty industrial applications. Both types serve as essential packaging solutions, with jute sacking favored for sustainability and PP sacking preferred for long-lasting performance.

Material Composition: Jute vs Polypropylene

Jute sacking is made from natural fibers derived from the jute plant, offering biodegradability and excellent breathability ideal for agricultural products. Polypropylene (PP) sacking consists of synthetic polymers, providing high tensile strength, moisture resistance, and durability suited for heavy-duty packaging. The natural composition of jute reduces environmental impact, while PP sacks deliver superior resistance to wear and chemical exposure.

Environmental Impact: Jute Sacking vs PP Sacking

Jute sacking is biodegradable and compostable, significantly reducing environmental pollution compared to polypropylene (PP) sacking, which is non-biodegradable and contributes to long-term plastic waste accumulation. The production of jute requires less energy and emits fewer greenhouse gases than PP manufacturing, supporting lower carbon footprints. Furthermore, jute sacks promote soil health when decomposed, whereas PP sacks often persist in ecosystems, harming wildlife and contaminating soil and water sources.

Durability and Strength Comparison

Jute sacking offers natural fiber strength with high tensile resilience but tends to degrade faster under prolonged moisture exposure compared to polypropylene (PP) sacking, which boasts superior water resistance and increased durability. PP sacking demonstrates enhanced tear resistance and longevity, making it ideal for heavy-duty applications, whereas jute sacking excels in biodegradability and breathability, important for agricultural produce storage. The strength-to-weight ratio of PP sacking typically surpasses that of jute, resulting in greater efficiency for transport and repeated usage scenarios.

Cost Analysis: Jute Sacks vs PP Sacks

Jute sacks typically cost more upfront due to natural fiber production and processing expenses, but offer superior biodegradability and eco-friendliness compared to polypropylene (PP) sacks. PP sacks are generally cheaper and more durable, providing better resistance to moisture and chemicals, which reduces replacement frequency in industrial use. Considering long-term environmental impact and disposal costs, jute sacks may present greater value despite higher initial investment.

Biodegradability and Eco-Friendliness

Jute sacking is highly biodegradable and decomposes naturally within a few months, making it an eco-friendly alternative to polypropylene (PP) sacking, which can take hundreds of years to break down. The natural fibers in jute reduce plastic pollution and lower carbon footprints due to sustainable cultivation and processing methods. In contrast, PP sacking, derived from petroleum, contributes to microplastic contamination and reliance on non-renewable resources.

Application Industries: Where Jute and PP Sacks Excel

Jute sacking excels in agriculture, horticulture, and food industries due to its natural breathability and biodegradability, making it ideal for storing potatoes, onions, and coffee beans. PP (polypropylene) sacking is preferred in construction, chemical, and industrial sectors for its strength, durability, and resistance to moisture and chemicals, suitable for cement, fertilizers, and sand. Both materials serve distinct markets where their unique properties meet specific packaging and transportation requirements.

Sourcing and Manufacturing Processes

Jute sacking is derived from the natural fibers of the jute plant, primarily sourced from countries like India and Bangladesh, involving traditional retting and spinning processes that emphasize eco-friendly and biodegradable characteristics. In contrast, polypropylene (PP) sacking is manufactured from synthetic polymers through petrochemical extraction and polymerization, resulting in a more uniform and water-resistant material but with higher environmental impact. The sourcing of jute depends heavily on agricultural conditions and manual labor, whereas PP sacks rely on advanced industrial production with petrochemical inputs.

Reusability and Recycling Potential

Jute sacking offers superior reusability due to its natural fiber strength and breathability, allowing multiple uses before deterioration. PP (polypropylene) sacking, while durable, has limited reusability as synthetic fibers degrade faster under sunlight and wear. In terms of recycling potential, jute is biodegradable and compostable, making it environmentally friendly, whereas PP sacking requires industrial recycling processes and can contribute to plastic pollution if not properly managed.

Future Trends: Jute Sacking vs PP Sacking

Future trends indicate a growing preference for jute sacking due to its biodegradability and eco-friendly properties, aligning with global sustainability goals. Polypropylene (PP) sacking, while cheaper and more durable, faces increasing scrutiny over environmental impact and recycling challenges. Innovations in Jute sacking, including enhanced durability and treatment techniques, are anticipated to expand its market share as environmental regulations tighten worldwide.

Jute Sacking vs PP Sacking Infographic

materialdif.com

materialdif.com