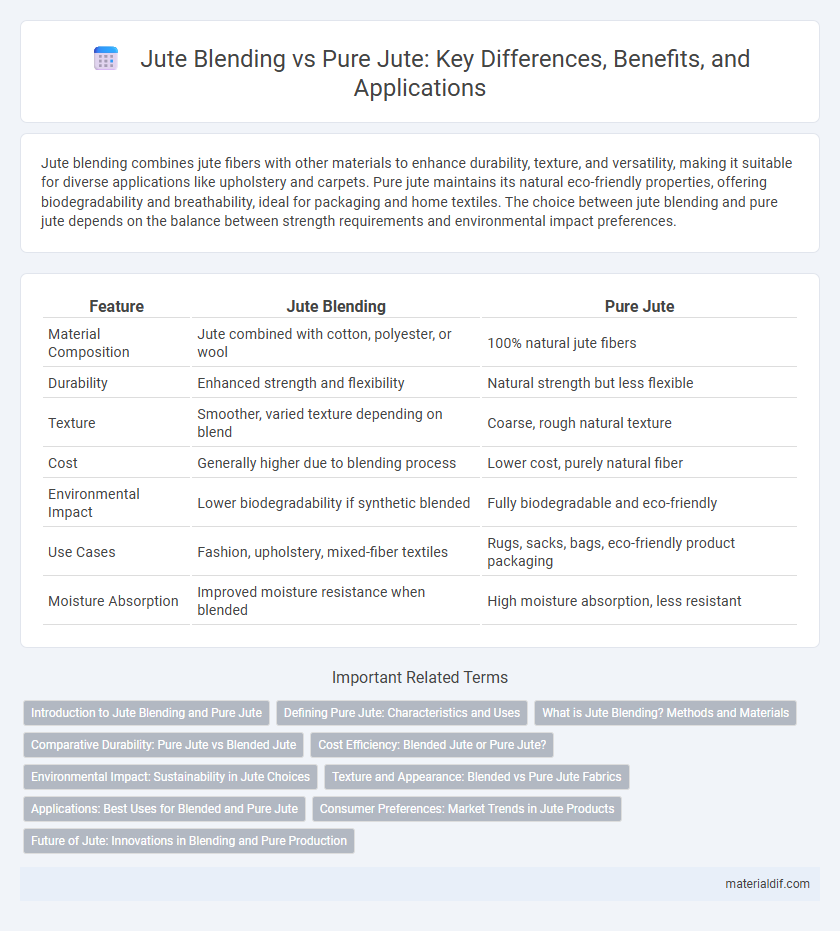

Jute blending combines jute fibers with other materials to enhance durability, texture, and versatility, making it suitable for diverse applications like upholstery and carpets. Pure jute maintains its natural eco-friendly properties, offering biodegradability and breathability, ideal for packaging and home textiles. The choice between jute blending and pure jute depends on the balance between strength requirements and environmental impact preferences.

Table of Comparison

| Feature | Jute Blending | Pure Jute |

|---|---|---|

| Material Composition | Jute combined with cotton, polyester, or wool | 100% natural jute fibers |

| Durability | Enhanced strength and flexibility | Natural strength but less flexible |

| Texture | Smoother, varied texture depending on blend | Coarse, rough natural texture |

| Cost | Generally higher due to blending process | Lower cost, purely natural fiber |

| Environmental Impact | Lower biodegradability if synthetic blended | Fully biodegradable and eco-friendly |

| Use Cases | Fashion, upholstery, mixed-fiber textiles | Rugs, sacks, bags, eco-friendly product packaging |

| Moisture Absorption | Improved moisture resistance when blended | High moisture absorption, less resistant |

Introduction to Jute Blending and Pure Jute

Jute blending combines natural jute fibers with synthetic or other natural fibers to enhance durability, flexibility, and resistance to moisture compared to pure jute, which is 100% natural and biodegradable but more prone to wear and environmental impact. Pure jute is valued for its eco-friendly properties, breathability, and traditional texture, making it ideal for sustainable packaging and textiles, while blended jute fabrics are preferred for applications requiring added strength and longevity. The choice between jute blending and pure jute depends on balancing environmental benefits with functional performance in diverse industrial uses.

Defining Pure Jute: Characteristics and Uses

Pure jute is a natural fiber derived from the Corchorus plant, known for its biodegradable, strong, and breathable characteristics, making it ideal for eco-friendly products. It exhibits a coarse texture, high tensile strength, and excellent moisture absorption, which makes it suitable for manufacturing sacks, rugs, and ropes. Pure jute's durability and affordability contribute to its popularity in traditional packaging and sustainable textile applications.

What is Jute Blending? Methods and Materials

Jute blending involves combining jute fibers with other natural or synthetic fibers to enhance durability, texture, and versatility in textile applications. Common methods include mechanical mixing and carding, where jute is blended with cotton, wool, or polyester to produce fabrics that balance strength and softness. These blends improve resistance to wear and tear, making products suitable for a wider range of uses compared to pure jute.

Comparative Durability: Pure Jute vs Blended Jute

Pure jute exhibits high tensile strength but tends to be less resistant to moisture and abrasion compared to blended jute. Jute blends, often mixed with synthetic fibers like polyester or cotton, enhance durability by improving resistance to wear, tear, and environmental factors. In applications requiring prolonged exposure to rough use or humidity, blended jute outperforms pure jute by maintaining structural integrity and longevity.

Cost Efficiency: Blended Jute or Pure Jute?

Blended jute, combining natural jute fibers with synthetic or cotton materials, offers enhanced durability and cost efficiency compared to pure jute by reducing raw material expenses and improving product lifespan. Pure jute, while eco-friendly and biodegradable, tends to have higher production costs and lower resistance to wear and moisture, leading to increased replacement frequency. For industries focused on budget constraints and product longevity, blended jute provides a more cost-effective solution without compromising essential jute characteristics.

Environmental Impact: Sustainability in Jute Choices

Blending jute with synthetic fibers reduces biodegradability, increasing environmental impact compared to pure jute, which is 100% biodegradable and compostable. Pure jute cultivation requires fewer pesticides and water, promoting sustainable agriculture and reducing soil degradation. Opting for pure jute supports zero-waste practices and lowers carbon footprint, enhancing overall sustainability in textile production.

Texture and Appearance: Blended vs Pure Jute Fabrics

Blended jute fabrics combine jute fibers with materials like cotton or polyester, resulting in a smoother texture and enhanced durability compared to pure jute. Pure jute fabric exhibits a coarse texture with a natural, rustic appearance that highlights its organic fiber structure. The visual appeal of blended jute is often more refined and versatile, making it suitable for diverse applications where softness and aesthetic uniformity are desired.

Applications: Best Uses for Blended and Pure Jute

Jute blending enhances durability, making it ideal for industrial applications such as bags, carpets, and upholstery where strength and resistance are crucial. Pure jute retains its natural softness and biodegradability, preferred for eco-friendly products like shopping bags, ropes, and home decor. Blended jute often incorporates cotton or synthetic fibers, expanding its use in fashion textiles and composite materials requiring improved flexibility and texture.

Consumer Preferences: Market Trends in Jute Products

Consumer preferences in jute products are increasingly leaning towards blended jute fabrics due to their enhanced durability, softness, and cost-effectiveness compared to pure jute. Market trends indicate a rising demand for jute blends combined with cotton, polyester, or other fibers, catering to diverse applications such as fashion, home decor, and packaging. Pure jute remains favored for eco-friendly and traditional uses but faces competition as blended jute delivers improved performance and versatility.

Future of Jute: Innovations in Blending and Pure Production

Innovations in jute blending technologies enhance fabric durability and versatility, addressing market demands for sustainable yet robust materials. Pure jute advancements focus on improving fiber quality and eco-friendly processing methods to maintain natural biodegradability and strength. The future of jute revolves around integrating cutting-edge blending techniques with pure jute optimization to create high-performance, sustainable textiles for diverse applications.

Jute Blending vs Pure Jute Infographic

materialdif.com

materialdif.com