Jute tape offers eco-friendly durability and a natural texture ideal for sustainable packaging, while polypropylene tape provides stronger adhesive properties and water resistance for heavy-duty applications. Jute tape is biodegradable and compostable, making it a preferred choice for environmentally conscious consumers. Polypropylene tape outperforms jute in terms of stretch and tensile strength, suitable for long-lasting, secure sealing.

Table of Comparison

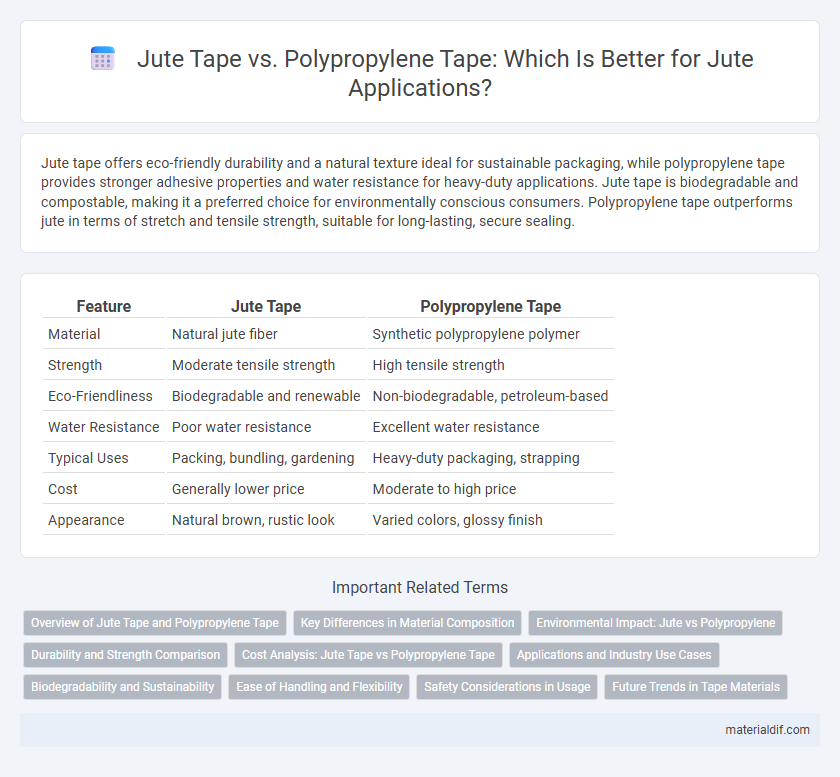

| Feature | Jute Tape | Polypropylene Tape |

|---|---|---|

| Material | Natural jute fiber | Synthetic polypropylene polymer |

| Strength | Moderate tensile strength | High tensile strength |

| Eco-Friendliness | Biodegradable and renewable | Non-biodegradable, petroleum-based |

| Water Resistance | Poor water resistance | Excellent water resistance |

| Typical Uses | Packing, bundling, gardening | Heavy-duty packaging, strapping |

| Cost | Generally lower price | Moderate to high price |

| Appearance | Natural brown, rustic look | Varied colors, glossy finish |

Overview of Jute Tape and Polypropylene Tape

Jute tape is a natural fiber product known for its eco-friendliness, biodegradability, and strong tensile strength, making it ideal for sustainable packaging and crafting applications. Polypropylene tape, a synthetic option, offers superior water resistance, durability, and cost-effectiveness, widely used in industrial packaging and heavy-duty bundling. Both tapes serve distinct purposes, with jute tape favored for environmentally conscious uses and polypropylene tape chosen for robust, moisture-resistant sealing needs.

Key Differences in Material Composition

Jute tape is made from natural fibers derived from the jute plant, offering biodegradability and eco-friendly properties, whereas polypropylene tape consists of synthetic polymers that provide higher tensile strength and water resistance. The natural cellulose structure in jute contributes to its softness and breathability, contrasting with the hydrophobic nature of polypropylene, which enhances durability in moist conditions. These fundamental differences in material composition directly impact their applications, with jute tape favored in sustainable packaging and polypropylene tape used for heavy-duty industrial purposes.

Environmental Impact: Jute vs Polypropylene

Jute tape is biodegradable and compostable, making it an eco-friendly alternative to polypropylene tape, which is derived from non-renewable petroleum and is non-biodegradable. The natural fibers of jute decompose quickly in soil, significantly reducing landfill waste and microplastic pollution compared to polypropylene. Choosing jute tape supports sustainable agriculture and lowers the carbon footprint associated with plastic tape production and disposal.

Durability and Strength Comparison

Jute tape offers natural strength and moderate durability, making it ideal for eco-friendly packaging and bundling applications where biodegradability is prioritized. Polypropylene tape provides superior tensile strength and high resistance to moisture, making it more durable for heavy-duty sealing and long-term storage. The choice between jute tape and polypropylene tape depends on the specific requirements for environmental sustainability versus enhanced durability and strength.

Cost Analysis: Jute Tape vs Polypropylene Tape

Jute tape offers a cost-effective solution due to its natural fibers and biodegradability, often priced lower than synthetic alternatives, making it suitable for eco-conscious businesses aiming to reduce packaging expenses. Polypropylene tape, although generally more expensive upfront, provides superior durability and water resistance, which can lower replacement and damage costs in the long term. Considering the total cost of ownership, jute tape benefits industries prioritizing sustainability and budget, while polypropylene tape favors applications requiring enhanced strength and longevity.

Applications and Industry Use Cases

Jute tape serves eco-friendly packaging, gardening, and craft industries by providing biodegradable, natural fiber reinforcement ideal for sustainable product bundling and horticultural support. Polypropylene tape is widely used in shipping, palletizing, and industrial packaging due to its high tensile strength, resistance to moisture, and cost-effectiveness for securing heavy loads. Manufacturing, logistics, and construction sectors favor polypropylene tape for durability, while agriculture and artisanal markets prefer jute tape for its environmental benefits and compatibility with organic materials.

Biodegradability and Sustainability

Jute tape is a biodegradable and sustainable option made from natural plant fibers, decomposing quickly without harming the environment. Polypropylene tape, composed of synthetic plastic, takes several decades to break down and contributes to long-term pollution. Choosing jute tape supports eco-friendly packaging by reducing plastic waste and promoting renewable materials.

Ease of Handling and Flexibility

Jute tape offers superior flexibility due to its natural fibers, making it easier to bend and wrap around irregular shapes compared to polypropylene tape. The organic composition of jute tape provides a softer texture and better grip, enhancing ease of handling during manual application. Polypropylene tape, while durable and resistant to moisture, tends to be stiffer and less pliable, which can limit maneuverability in detailed packing or bundling tasks.

Safety Considerations in Usage

Jute tape offers superior breathability and eco-friendliness, reducing the risk of heat buildup and chemical exposure during use, which enhances safety in packaging and agricultural applications. Polypropylene tape, while stronger and more resistant to moisture, can pose inhalation hazards from microplastics and may cause skin irritation due to synthetic material composition. Careful handling and proper ventilation are essential when using polypropylene tape to mitigate potential health risks, whereas jute tape's natural fibers provide a safer choice for environments requiring non-toxic and biodegradable materials.

Future Trends in Tape Materials

Jute tape, valued for its biodegradability and natural fiber composition, is gaining traction in sustainable packaging as environmental regulations tighten worldwide. Polypropylene tape remains popular due to its strength and cost-effectiveness but faces scrutiny over plastic waste concerns and recyclability challenges. Emerging trends indicate a shift toward hybrid tapes combining natural fibers like jute with biodegradable polymers to balance durability with eco-friendly performance.

Jute Tape vs Polypropylene Tape Infographic

materialdif.com

materialdif.com