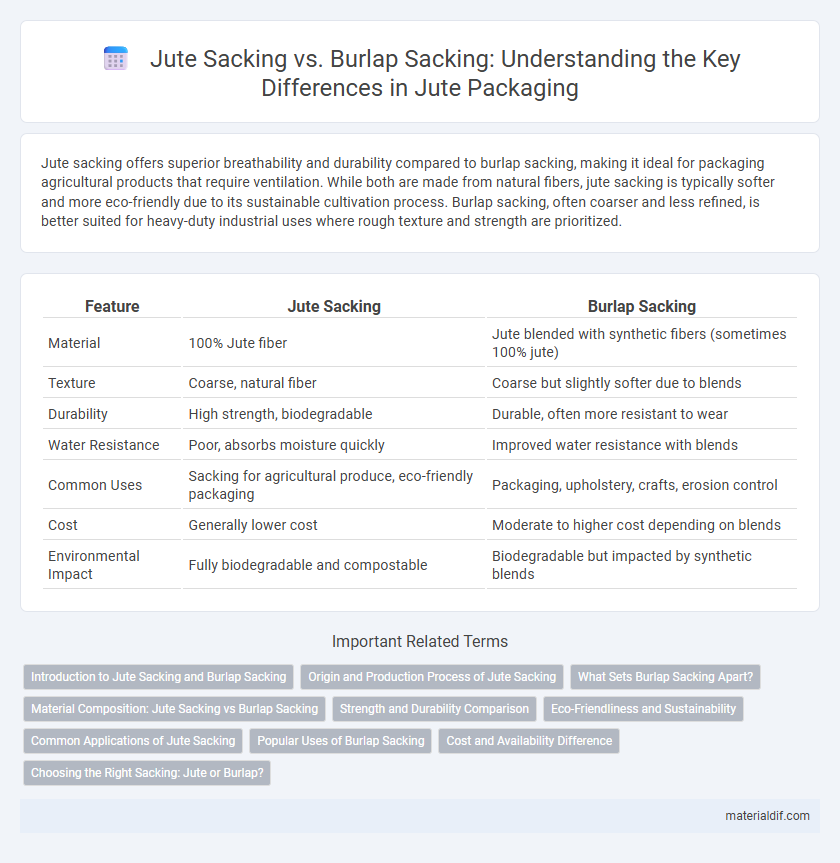

Jute sacking offers superior breathability and durability compared to burlap sacking, making it ideal for packaging agricultural products that require ventilation. While both are made from natural fibers, jute sacking is typically softer and more eco-friendly due to its sustainable cultivation process. Burlap sacking, often coarser and less refined, is better suited for heavy-duty industrial uses where rough texture and strength are prioritized.

Table of Comparison

| Feature | Jute Sacking | Burlap Sacking |

|---|---|---|

| Material | 100% Jute fiber | Jute blended with synthetic fibers (sometimes 100% jute) |

| Texture | Coarse, natural fiber | Coarse but slightly softer due to blends |

| Durability | High strength, biodegradable | Durable, often more resistant to wear |

| Water Resistance | Poor, absorbs moisture quickly | Improved water resistance with blends |

| Common Uses | Sacking for agricultural produce, eco-friendly packaging | Packaging, upholstery, crafts, erosion control |

| Cost | Generally lower cost | Moderate to higher cost depending on blends |

| Environmental Impact | Fully biodegradable and compostable | Biodegradable but impacted by synthetic blends |

Introduction to Jute Sacking and Burlap Sacking

Jute sacking and burlap sacking are both made from natural fibers derived from the jute plant, known for their durability and biodegradability. Jute sacking is typically woven tightly for heavy-duty packaging and agricultural uses, while burlap sacking features a coarser weave suited for decorative purposes and lightweight storage. Both materials serve as eco-friendly alternatives to synthetic sacks, prominently used in industries like farming, shipping, and interior design.

Origin and Production Process of Jute Sacking

Jute sacking is primarily made from natural jute fibers cultivated in regions like India and Bangladesh, where the climate supports rapid growth and high fiber quality. The production process involves retting, stripping, and spinning the jute fibers into strong yarns suitable for weaving durable sacks. Unlike burlap, which can be woven from jute or other fibers such as hemp or synthetic blends, jute sacking specifically utilizes pure jute fibers, ensuring a biodegradable and eco-friendly product.

What Sets Burlap Sacking Apart?

Burlap sacking is distinguished by its coarser weave and lighter weight compared to traditional jute sacking, making it more breathable and flexible for packaging applications. The natural fiber composition of burlap allows for superior moisture-wicking properties and biodegradability, which enhances its sustainability profile. Unlike jute sacking, burlap is often used in decorative and craft projects due to its rustic texture and aesthetic appeal.

Material Composition: Jute Sacking vs Burlap Sacking

Jute sacking is primarily made from natural jute fibers, known for their strength, biodegradability, and moisture resistance, making it ideal for packaging agricultural products. Burlap sacking, often derived from jute but sometimes blended with other fibers like hemp or synthetic reinforcements, typically has a coarser texture and lower tensile strength compared to pure jute sacking. The material composition differences influence durability, breathability, and suitability for various industrial and decorative applications.

Strength and Durability Comparison

Jute sacking typically offers higher strength and durability compared to burlap sacking due to its denser fiber weave and natural resilience. Burlap, often made from loosely woven jute or hemp fibers, tends to be less robust and more prone to tearing under heavy loads. The superior tensile strength of jute sacking makes it ideal for industrial applications requiring long-lasting and heavy-duty packaging solutions.

Eco-Friendliness and Sustainability

Jute sacking offers superior eco-friendliness due to its fully biodegradable and renewable natural fiber composition, which decomposes faster than burlap made from mixed fibers or synthetic blends. Sustainability is enhanced in jute sacking production by its low water and pesticide requirements, making it an environmentally responsible choice compared to burlap alternatives. Choosing jute sacking supports circular economies by reducing plastic waste and promoting sustainable agriculture practices, reinforcing its role as a green packaging option.

Common Applications of Jute Sacking

Jute sacking is widely used in agriculture for packaging crops like potatoes, onions, and coffee beans due to its breathability and biodegradability. Its natural fiber composition allows for excellent moisture control, making it ideal for storing and transporting perishable goods. Burlap sacking, a type of jute fabric, is commonly applied in landscaping, erosion control, and decorative crafts because of its coarse texture and durability.

Popular Uses of Burlap Sacking

Burlap sacking, made from jute fibers, is widely favored for agricultural and gardening uses such as storing potatoes, onions, and other produce due to its breathability and durability. It is also popular in landscaping for erosion control and as a biodegradable weed barrier, making it environmentally sustainable. Furthermore, burlap sacks are commonly used in crafts and upholstery, where their coarse texture adds rustic charm and functional strength.

Cost and Availability Difference

Jute sacking is generally more cost-effective and widely available than burlap sacking, making it a preferred choice for bulk packaging and agricultural uses. Burlap, often made from jute but sometimes from other fibers like hemp, tends to be pricier due to its thicker weave and durability, resulting in less availability in some markets. The cost difference is influenced by variations in weave density and fiber quality, with jute sacking dominating in supply due to its lighter weight and broader industrial demand.

Choosing the Right Sacking: Jute or Burlap?

Jute sacking offers superior strength and durability, making it ideal for heavy-duty agricultural and industrial uses, while burlap sacking, usually made from jute or hemp fibers, provides a lighter, more breathable option suitable for packaging fragile items and decorative purposes. The choice between jute and burlap sacking depends on factors such as load capacity, moisture resistance, and intended application, with jute favored for robustness and burlap preferred for flexibility and aesthetic appeal. Evaluating environmental impact also favors jute, given its renewable properties and biodegradability compared to some burlap blends.

Jute Sacking vs Burlap Sacking Infographic

materialdif.com

materialdif.com