Jute webbing offers natural biodegradability and a rustic appearance, making it ideal for eco-friendly packaging and upholstery projects. Polypropylene webbing provides superior strength, water resistance, and durability, suited for heavy-duty applications like cargo straps and outdoor gear. Choosing between them depends on the need for sustainability versus performance in moisture and load-bearing conditions.

Table of Comparison

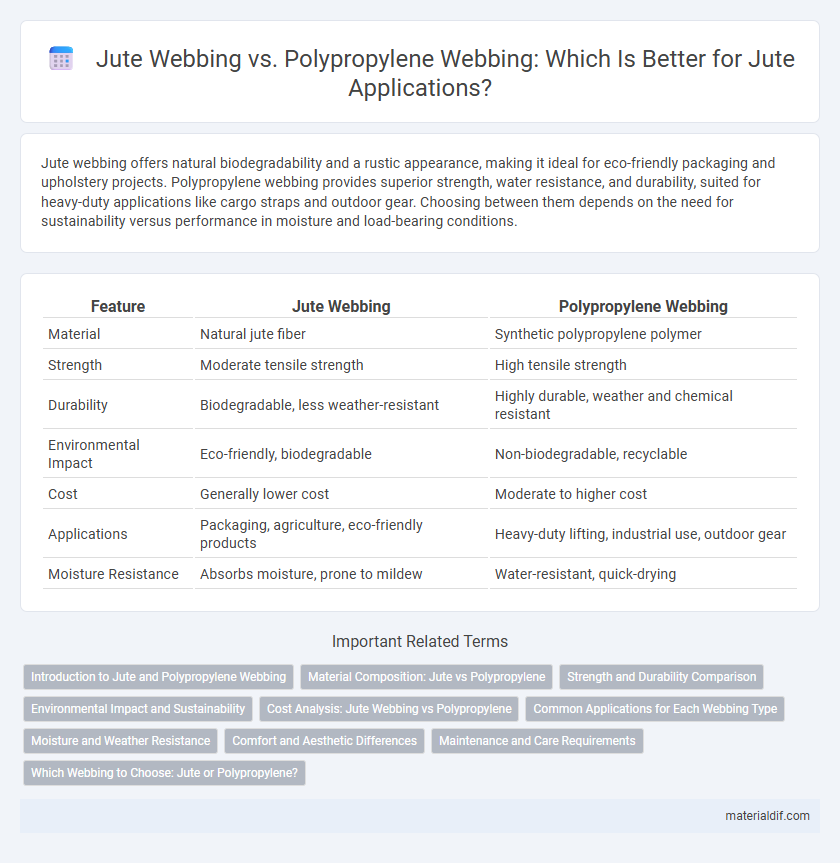

| Feature | Jute Webbing | Polypropylene Webbing |

|---|---|---|

| Material | Natural jute fiber | Synthetic polypropylene polymer |

| Strength | Moderate tensile strength | High tensile strength |

| Durability | Biodegradable, less weather-resistant | Highly durable, weather and chemical resistant |

| Environmental Impact | Eco-friendly, biodegradable | Non-biodegradable, recyclable |

| Cost | Generally lower cost | Moderate to higher cost |

| Applications | Packaging, agriculture, eco-friendly products | Heavy-duty lifting, industrial use, outdoor gear |

| Moisture Resistance | Absorbs moisture, prone to mildew | Water-resistant, quick-drying |

Introduction to Jute and Polypropylene Webbing

Jute webbing, derived from natural fibers of the jute plant, is biodegradable, eco-friendly, and known for its strength, durability, and coarse texture ideal for craft and upholstery uses. Polypropylene webbing, a synthetic polymer made from polypropylene resin, offers lightweight, water-resistant, and high tensile strength properties commonly used in outdoor gear, straps, and safety harnesses. Both webbings serve distinct purposes with jute emphasizing sustainability and natural aesthetics, while polypropylene provides enhanced durability and resistance to environmental elements.

Material Composition: Jute vs Polypropylene

Jute webbing is made from natural plant fibers derived from the jute plant's bast, offering biodegradability and eco-friendliness. Polypropylene webbing consists of synthetic thermoplastic polymer fibers known for their high tensile strength, resistance to moisture, and durability. The natural cellulose content in jute contrasts with the petrochemical-based polypropylene, influencing their environmental impact and performance characteristics.

Strength and Durability Comparison

Jute webbing offers natural strength with moderate durability, making it suitable for eco-friendly packaging and lightweight load-bearing applications, but it tends to degrade faster under prolonged moisture exposure. Polypropylene webbing provides superior tensile strength and exceptional resistance to abrasion, chemicals, and UV damage, resulting in greater durability for heavy-duty industrial use and outdoor environments. The choice between jute and polypropylene webbing depends on specific strength requirements and environmental conditions, with polypropylene generally outperforming jute in long-term durability.

Environmental Impact and Sustainability

Jute webbing is biodegradable and compostable, making it an eco-friendly choice with minimal environmental impact compared to polypropylene webbing, which is derived from non-renewable petroleum and contributes to plastic pollution. Jute cultivation supports sustainable agriculture by improving soil quality and requiring fewer pesticides, while polypropylene production involves energy-intensive processes and generates long-lasting waste. Choosing jute webbing promotes renewable resource use and reduces carbon footprint, aligning with sustainable manufacturing practices and environmental conservation goals.

Cost Analysis: Jute Webbing vs Polypropylene

Jute webbing offers a cost-effective alternative to polypropylene webbing due to its natural fiber composition and lower raw material expenses, making it ideal for eco-friendly applications. Polypropylene webbing generally incurs higher costs linked to synthetic production and chemical treatments, although it delivers superior durability and resistance to environmental factors. Evaluating long-term value, jute webbing reduces expenses in biodegradable disposability, while polypropylene incurs additional costs related to environmental impact and recycling challenges.

Common Applications for Each Webbing Type

Jute webbing is commonly used in eco-friendly products such as upholstery, bag handles, and gardening support due to its natural biodegradability and tensile strength. Polypropylene webbing finds widespread application in outdoor gear, luggage straps, and safety harnesses because of its water resistance, durability, and lightweight properties. Both types serve distinct purposes, with jute preferred for sustainable, natural material needs, and polypropylene favored where synthetic resilience is essential.

Moisture and Weather Resistance

Jute webbing is biodegradable and offers moderate moisture absorption but tends to degrade faster when exposed to prolonged wet conditions, limiting its durability in humid or rainy environments. In contrast, polypropylene webbing exhibits superior moisture resistance due to its synthetic nature, maintaining strength and integrity in wet and variable weather conditions without absorbing water. Polypropylene's resistance to mold, mildew, and UV rays makes it ideal for outdoor applications where consistent exposure to moisture and weather elements occurs.

Comfort and Aesthetic Differences

Jute webbing offers superior comfort due to its natural fiber composition, providing breathability and a softer texture that reduces skin irritation compared to polypropylene webbing. The aesthetic appeal of jute is characterized by its rustic, organic look with earthy tones and slight texture variations, making it ideal for eco-friendly and vintage-inspired designs. Polypropylene webbing, on the other hand, features a smooth, synthetic finish available in vibrant colors, but lacks the tactile warmth and natural charm inherent to jute.

Maintenance and Care Requirements

Jute webbing requires gentle cleaning with mild soaps and air drying to maintain its natural fibers and prevent mold growth. Polypropylene webbing is more resistant to moisture and mildew, allowing easy cleaning with water and detergents without damaging the material. Regular inspection of both webbings ensures durability, but polypropylene generally demands less maintenance due to its synthetic properties.

Which Webbing to Choose: Jute or Polypropylene?

Jute webbing offers natural biodegradability, breathability, and a rustic aesthetic, making it ideal for eco-friendly applications and artisanal crafts, whereas polypropylene webbing excels in durability, water resistance, and tensile strength, suitable for heavy-duty uses like outdoor gear and industrial straps. Choosing jute webbing supports sustainable practices and provides a softer texture, while polypropylene webbing prioritizes longevity and performance in harsh environments. For environmentally conscious projects, jute is preferable; for high-load or moisture-prone conditions, polypropylene is the better choice.

Jute Webbing vs Polypropylene Webbing Infographic

materialdif.com

materialdif.com