Jute geo-textiles offer superior biodegradability and environmental friendliness compared to synthetic geo-textiles, making them ideal for sustainable construction and erosion control projects. Their natural fibers provide excellent soil reinforcement and moisture retention while decomposing naturally over time, reducing long-term ecological impact. Synthetic geo-textiles, though durable and resistant to chemicals and UV radiation, pose challenges related to non-biodegradability and environmental pollution after use.

Table of Comparison

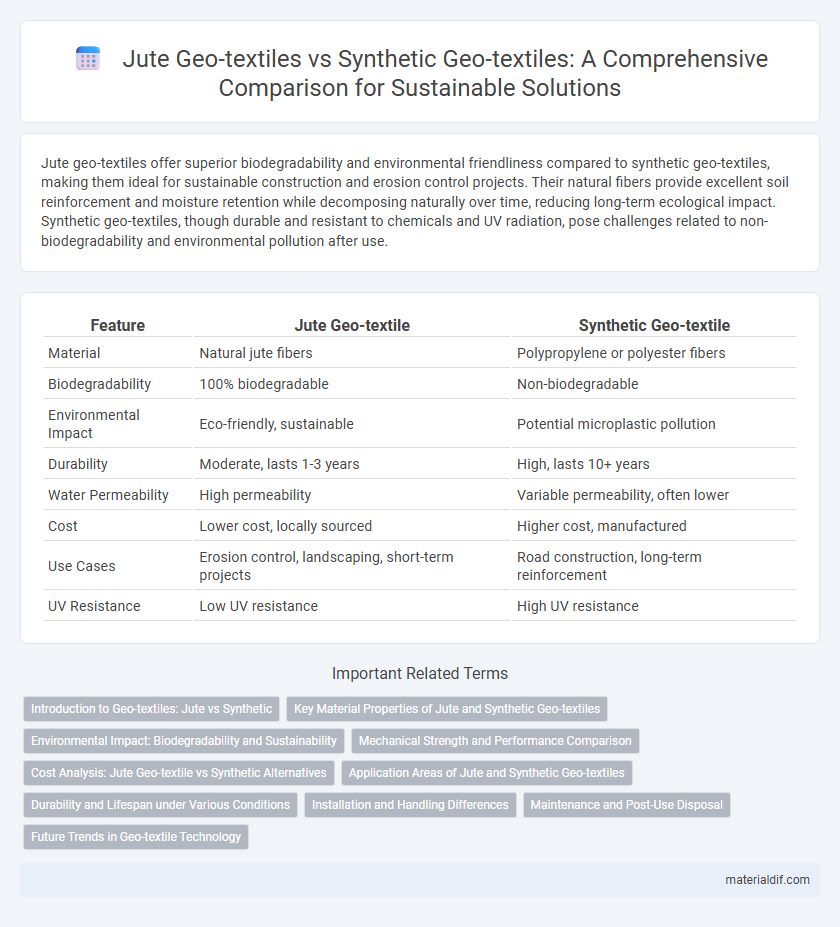

| Feature | Jute Geo-textile | Synthetic Geo-textile |

|---|---|---|

| Material | Natural jute fibers | Polypropylene or polyester fibers |

| Biodegradability | 100% biodegradable | Non-biodegradable |

| Environmental Impact | Eco-friendly, sustainable | Potential microplastic pollution |

| Durability | Moderate, lasts 1-3 years | High, lasts 10+ years |

| Water Permeability | High permeability | Variable permeability, often lower |

| Cost | Lower cost, locally sourced | Higher cost, manufactured |

| Use Cases | Erosion control, landscaping, short-term projects | Road construction, long-term reinforcement |

| UV Resistance | Low UV resistance | High UV resistance |

Introduction to Geo-textiles: Jute vs Synthetic

Jute geo-textiles offer natural biodegradability and excellent moisture retention, making them ideal for erosion control and soil stabilization in environmentally sensitive projects. Synthetic geo-textiles, typically made from polypropylene or polyester, provide higher tensile strength, durability, and resistance to chemicals and UV radiation, making them suitable for long-term infrastructure applications. Choosing between jute and synthetic geo-textiles depends on project requirements, environmental impact considerations, and desired service life.

Key Material Properties of Jute and Synthetic Geo-textiles

Jute geo-textiles exhibit excellent biodegradability, natural fiber strength, and high moisture retention, making them ideal for short-term erosion control and environmental projects. Synthetic geo-textiles, typically made from polypropylene or polyester, offer superior tensile strength, durability, and resistance to UV degradation, suitable for long-term soil stabilization and reinforcement. The choice between jute and synthetic geo-textiles depends on project requirements, balancing eco-friendliness with mechanical performance and lifespan.

Environmental Impact: Biodegradability and Sustainability

Jute geo-textiles offer superior environmental benefits due to their natural biodegradability and renewable nature, decomposing within months and enriching soil quality without leaving harmful residues. Synthetic geo-textiles, primarily made from non-biodegradable polymers like polypropylene, persist in the environment for decades, contributing to plastic pollution and microplastic contamination. The sustainable harvesting of jute fibers reduces reliance on fossil fuels and supports carbon sequestration, making jute geo-textiles a more eco-friendly alternative for erosion control and soil stabilization projects.

Mechanical Strength and Performance Comparison

Jute geo-textiles offer natural biodegradability with moderate mechanical strength, typically exhibiting tensile strength between 15 to 30 kN/m, suitable for temporary erosion control and soil stabilization. Synthetic geo-textiles, commonly made from polypropylene or polyester, provide superior mechanical strength ranging from 40 to 100 kN/m, ensuring enhanced durability, UV resistance, and prolonged performance under heavy load conditions. While synthetic geo-textiles excel in high-stress applications, jute geo-textiles remain cost-effective and environmentally sustainable for projects requiring moderate strength and short-term use.

Cost Analysis: Jute Geo-textile vs Synthetic Alternatives

Jute geo-textiles offer a cost-effective alternative to synthetic geo-textiles, with raw material expenses typically 30-50% lower due to the natural abundance and biodegradability of jute fibers. Synthetic geo-textiles, made from polypropylene or polyester, incur higher manufacturing and disposal costs, impacting long-term economic feasibility. Maintenance expenses for jute geo-textiles are reduced by their eco-friendly decomposition, whereas synthetic counterparts may require additional environmental management costs.

Application Areas of Jute and Synthetic Geo-textiles

Jute geo-textiles are extensively used in erosion control, soil stabilization, and vegetation growth due to their natural biodegradability and eco-friendly properties, making them ideal for agricultural and environmental applications. Synthetic geo-textiles, composed of polypropylene or polyester, are preferred in heavy-duty civil engineering projects such as road construction, drainage systems, and landfill lining because of their high tensile strength and durability. The contrasting application areas highlight jute's suitability for short-term ecological restoration and synthetic geo-textiles' effectiveness in long-term infrastructure support.

Durability and Lifespan under Various Conditions

Jute geo-textiles exhibit moderate durability with a typical lifespan of 1 to 3 years under normal environmental conditions due to their natural biodegradability and vulnerability to UV degradation and moisture. Synthetic geo-textiles, made from polypropylene or polyester, offer superior durability, often lasting 10 to 20 years, resisting UV exposure, chemicals, and microbial attacks more effectively. Selection depends on project longevity requirements and environmental impact considerations, with jute favored for temporary applications and synthetic materials preferred for long-term stability.

Installation and Handling Differences

Jute geo-textiles are biodegradable, lightweight, and easy to handle, requiring minimal specialized equipment for installation compared to synthetic geo-textiles, which often demand precise machinery and skilled labor. The natural fibers of jute conform well to uneven surfaces, facilitating quicker placement and reducing labor costs, while synthetic materials provide higher tensile strength but can be less adaptable during installation. Moisture sensitivity in jute necessitates timely deployment to prevent premature degradation, whereas synthetic geo-textiles offer greater resistance to environmental factors, resulting in longer on-site durability during handling and installation.

Maintenance and Post-Use Disposal

Jute geo-textiles require minimal maintenance due to their natural biodegradability and resistance to microbial attacks, reducing long-term environmental impact. Synthetic geo-textiles often need chemical treatments and specialized upkeep to prevent degradation and contamination over time. Post-use disposal of jute geo-textiles is environmentally friendly, as they decompose naturally without releasing harmful residues, unlike synthetic variants that may persist in landfills and contribute to plastic pollution.

Future Trends in Geo-textile Technology

Jute geo-textiles, derived from natural fibers, offer biodegradability and sustainability advantages over synthetic geo-textiles, which are primarily made from polypropylene or polyester. Emerging trends indicate a growing demand for eco-friendly materials in geo-textile applications, with jute gaining prominence due to its renewable nature and carbon sequestration potential. Innovations in hybrid geo-textiles integrating jute fibers with synthetic polymers are driving future advancements, enhancing durability while maintaining environmental benefits.

Jute Geo-textile vs Synthetic Geo-textile Infographic

materialdif.com

materialdif.com