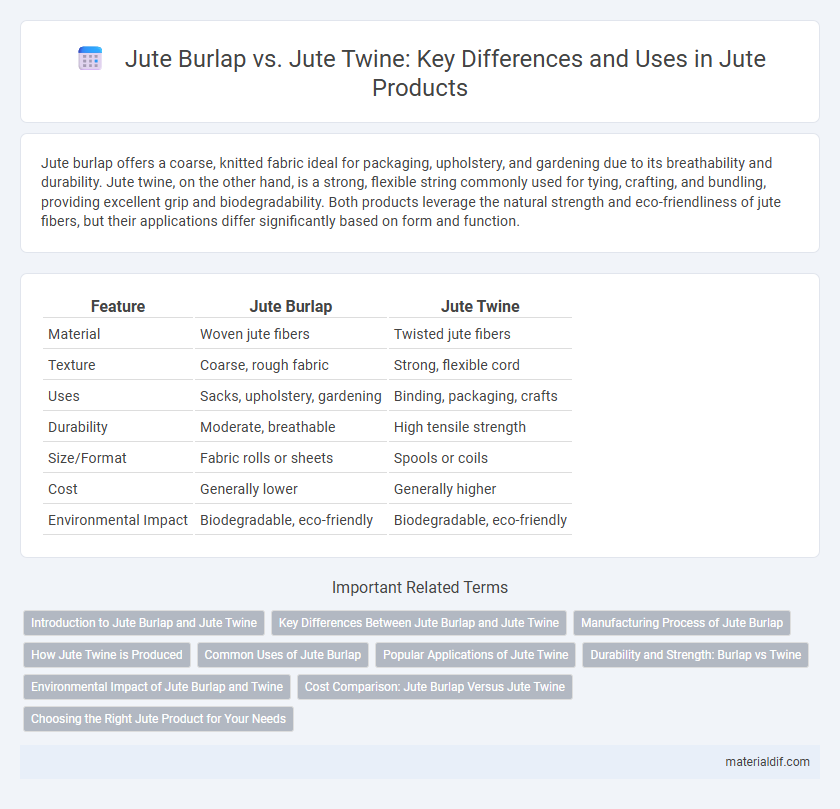

Jute burlap offers a coarse, knitted fabric ideal for packaging, upholstery, and gardening due to its breathability and durability. Jute twine, on the other hand, is a strong, flexible string commonly used for tying, crafting, and bundling, providing excellent grip and biodegradability. Both products leverage the natural strength and eco-friendliness of jute fibers, but their applications differ significantly based on form and function.

Table of Comparison

| Feature | Jute Burlap | Jute Twine |

|---|---|---|

| Material | Woven jute fibers | Twisted jute fibers |

| Texture | Coarse, rough fabric | Strong, flexible cord |

| Uses | Sacks, upholstery, gardening | Binding, packaging, crafts |

| Durability | Moderate, breathable | High tensile strength |

| Size/Format | Fabric rolls or sheets | Spools or coils |

| Cost | Generally lower | Generally higher |

| Environmental Impact | Biodegradable, eco-friendly | Biodegradable, eco-friendly |

Introduction to Jute Burlap and Jute Twine

Jute burlap is a coarse woven fabric made from natural jute fibers, widely used for packaging, agriculture, and home decor due to its durability and breathability. Jute twine, on the other hand, consists of thin, strong strands twisted together from jute fibers, commonly utilized for tying, crafting, and gardening applications. Both products are biodegradable, eco-friendly, and valued for their sustainable properties in various industrial and domestic contexts.

Key Differences Between Jute Burlap and Jute Twine

Jute burlap is a coarse woven fabric primarily used for sacks, upholstery, and gardening, providing strong breathability and durability. Jute twine consists of thin, twisted fibers mainly utilized for binding, packaging, and crafts, offering flexibility and tensile strength. The key differences lie in their form, application, and texture--burlap is a fabric suitable for covering and wrapping, while twine is a cord suited for tying and securing.

Manufacturing Process of Jute Burlap

Jute burlap is produced through a weaving process where spun jute fibers are interlaced to form a coarse fabric known for its durability and breathability. The manufacturing involves carding and spinning raw jute into yarn, which is then woven on looms to create the burlap cloth. In contrast, jute twine is made by twisting strands of jute fiber into strong, thin cords used primarily for binding and packaging.

How Jute Twine is Produced

Jute twine is produced through a detailed process starting with the harvesting of jute fibers from the Corchorus plant, followed by retting, stripping, and combing to extract strong, long fibers. These fibers are then spun into yarn using specialized spinning machines that twist them tightly to enhance strength and durability. The resulting twine is prized for its natural biodegradability and flexibility, making it ideal for binding, packaging, and agricultural applications.

Common Uses of Jute Burlap

Jute burlap is commonly used in agriculture for soil erosion control, landscaping, and plant protection due to its breathable and biodegradable properties. It serves as a versatile material for upholstery, crafts, and packaging, offering durability and eco-friendliness. Unlike jute twine, which is primarily used for tying and binding, jute burlap provides a larger surface area suitable for wrapping and covering applications.

Popular Applications of Jute Twine

Jute twine is widely used in agriculture for bundling crops, securing plants, and supporting climbing vegetables due to its strength and biodegradability. It's also popular in crafts and DIY projects, including macrame, gift wrapping, and home decor, offering an eco-friendly alternative to synthetic strings. Additionally, jute twine serves in packaging and gardening, ensuring sustainable practices in everyday applications.

Durability and Strength: Burlap vs Twine

Jute burlap offers greater durability and tensile strength due to its densely woven fabric structure, making it ideal for heavy-duty applications like sacks and upholstery. In contrast, jute twine, which consists of twisted fibers, provides flexibility and moderate strength suitable for bundling, gardening, and crafting tasks. While both are biodegradable and eco-friendly, burlap's robust weave ensures superior resistance to wear and tear compared to the thinner, more pliable twine.

Environmental Impact of Jute Burlap and Twine

Jute burlap and jute twine both offer eco-friendly benefits, as they are biodegradable and derived from renewable natural fibers. Jute burlap, often used in packaging and upholstery, has a lower environmental impact due to its minimal processing and longer lifespan compared to synthetic alternatives. Jute twine provides sustainable binding and gardening solutions, reducing plastic use and enhancing soil health through natural decomposition.

Cost Comparison: Jute Burlap Versus Jute Twine

Jute burlap typically costs more per yard than jute twine due to its heavier, woven fabric structure suited for packaging and upholstery. Jute twine, being a thinner, flexible cord, is generally less expensive and widely used for gardening, crafts, and tying purposes. The price difference reflects their distinct production processes and end-use applications, with burlap offering durability that justifies its higher cost.

Choosing the Right Jute Product for Your Needs

Jute burlap offers a coarse, breathable fabric ideal for gardening, upholstery, and packaging, providing robust moisture retention and biodegradability. Jute twine, made from twisted natural fibers, suits binding, crafting, and gardening tasks requiring strength and flexibility without bulk. Selecting the right jute product depends on the application: choose burlap for coverage and protection, and twine for tying or detailed work.

Jute Burlap vs Jute Twine Infographic

materialdif.com

materialdif.com