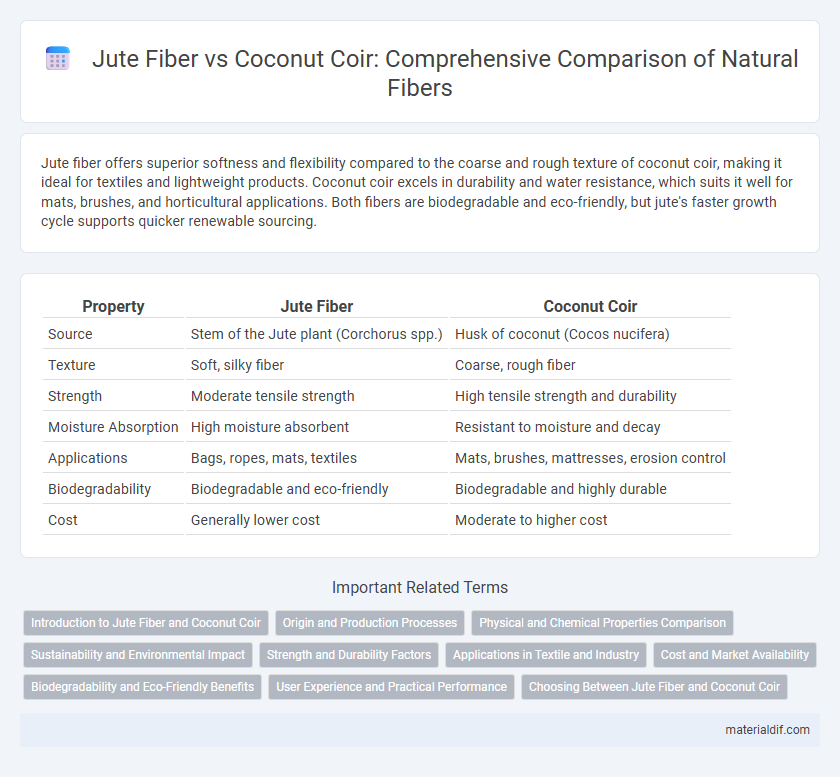

Jute fiber offers superior softness and flexibility compared to the coarse and rough texture of coconut coir, making it ideal for textiles and lightweight products. Coconut coir excels in durability and water resistance, which suits it well for mats, brushes, and horticultural applications. Both fibers are biodegradable and eco-friendly, but jute's faster growth cycle supports quicker renewable sourcing.

Table of Comparison

| Property | Jute Fiber | Coconut Coir |

|---|---|---|

| Source | Stem of the Jute plant (Corchorus spp.) | Husk of coconut (Cocos nucifera) |

| Texture | Soft, silky fiber | Coarse, rough fiber |

| Strength | Moderate tensile strength | High tensile strength and durability |

| Moisture Absorption | High moisture absorbent | Resistant to moisture and decay |

| Applications | Bags, ropes, mats, textiles | Mats, brushes, mattresses, erosion control |

| Biodegradability | Biodegradable and eco-friendly | Biodegradable and highly durable |

| Cost | Generally lower cost | Moderate to higher cost |

Introduction to Jute Fiber and Coconut Coir

Jute fiber, derived from the stems of the Corchorus plant, is known for its strong, biodegradable, and sustainable qualities, making it ideal for textiles, sacks, and eco-friendly packaging. Coconut coir, extracted from the husk of coconuts, excels in water retention, durability, and resistance to saltwater, commonly used in mats, brushes, and horticulture. Both natural fibers contribute significantly to sustainable materials, with jute offering enhanced tensile strength and coconut coir providing superior cushioning and moisture control.

Origin and Production Processes

Jute fiber originates primarily from the Corchorus plant species grown in the Ganges Delta region of India and Bangladesh, where it undergoes retting, a water-based microbial process that separates the fiber from the stalk. Coconut coir is extracted from the outer husk of mature coconuts harvested mainly in tropical countries like India, Sri Lanka, and the Philippines, involving retting or mechanical decortication to separate the coarse fibers. The production of jute fiber relies heavily on traditional retting ponds, whereas coir production incorporates both water retting and more mechanized processes to enhance fiber extraction efficiency.

Physical and Chemical Properties Comparison

Jute fiber exhibits higher tensile strength and moisture absorption compared to coconut coir, making it more suitable for textiles and ropes. Chemically, jute contains approximately 61-71% cellulose and 12-14% lignin, while coconut coir has lower cellulose (32-43%) but higher lignin content (40-45%), contributing to its coarse texture and enhanced resistance to microbial degradation. The difference in density, with jute around 1.3 g/cm3 and coir approximately 1.2 g/cm3, affects their applications in composite materials where lightweight and durability are critical factors.

Sustainability and Environmental Impact

Jute fiber is highly sustainable due to its fast growth cycle and minimal need for chemical fertilizers or pesticides, making it an eco-friendly alternative in natural fiber production. In contrast, coconut coir, while also biodegradable and renewable, requires significant water and energy for processing, which can increase its environmental footprint. Jute's ability to improve soil health through crop rotation and carbon sequestration further enhances its positive environmental impact compared to coconut coir.

Strength and Durability Factors

Jute fiber offers moderate tensile strength suitable for lightweight applications, while coconut coir exhibits superior durability and resistance to moisture and abrasion, making it ideal for heavy-duty uses. The lignin content in coir fibers enhances its rigidity and longevity compared to the softer, more flexible jute fibers. In terms of strength and durability, coconut coir outperforms jute, providing enhanced resilience in outdoor and high-wear environments.

Applications in Textile and Industry

Jute fiber excels in textile applications due to its softness, breathability, and biodegradability, making it ideal for producing sacks, bags, carpets, and upholstery. Coconut coir, with its coarse texture and high durability, is preferred for industrial uses such as mats, brushes, mattress stuffing, and erosion control materials. The choice between jute and coir depends on the required flexibility, strength, and moisture resistance for specific industrial or textile products.

Cost and Market Availability

Jute fiber is generally more cost-effective than coconut coir due to its widespread cultivation in countries like India and Bangladesh, leading to abundant market availability and lower production costs. Coconut coir, sourced mainly from coconut-producing regions such as the Philippines and India, tends to have higher costs due to more intensive processing requirements and seasonal supply fluctuations. The global trade volume for jute consistently surpasses that of coconut coir, making jute a preferred choice for budget-sensitive industries relying on natural fibers.

Biodegradability and Eco-Friendly Benefits

Jute fiber exhibits superior biodegradability compared to coconut coir, decomposing naturally within a few months and enriching soil nutrients without releasing harmful residues. Both fibers are renewable resources, but jute's lower lignin content enhances its eco-friendly profile by reducing processing energy and chemical use. This makes jute a preferred choice for sustainable textiles, packaging, and agricultural applications where environmental impact is a critical concern.

User Experience and Practical Performance

Jute fiber offers a softer texture and greater flexibility, making it more comfortable for products like rugs and upholstery, while coconut coir is coarser, providing superior durability and moisture resistance ideal for doormats and garden use. Users often prefer jute for indoor applications due to its breathability and biodegradability, whereas coir excels in outdoor conditions with its resilience against mold and rot. Practical performance varies as jute fibers degrade faster in damp environments, whereas coconut coir maintains structural integrity longer under heavy exposure.

Choosing Between Jute Fiber and Coconut Coir

Jute fiber offers a softer texture and higher tensile strength, making it ideal for textiles and upholstery, whereas coconut coir provides superior durability and water resistance suited for mats and brushes. Selecting between jute and coconut coir depends on the application requirements, with jute favored for eco-friendly fabric products and coir for heavy-duty, moisture-prone environments. Both fibers are biodegradable and renewable, but their distinct physical properties guide optimal material choice.

Jute Fiber vs Coconut Coir Infographic

materialdif.com

materialdif.com