Jute yarn is a natural, biodegradable fiber known for its breathability, making it ideal for eco-friendly packaging and textiles. Polypropylene yarn, a synthetic material, offers superior strength, moisture resistance, and durability, commonly used in heavy-duty applications like sacks and geotextiles. Choosing between jute and polypropylene yarn depends on environmental impact priorities versus performance requirements.

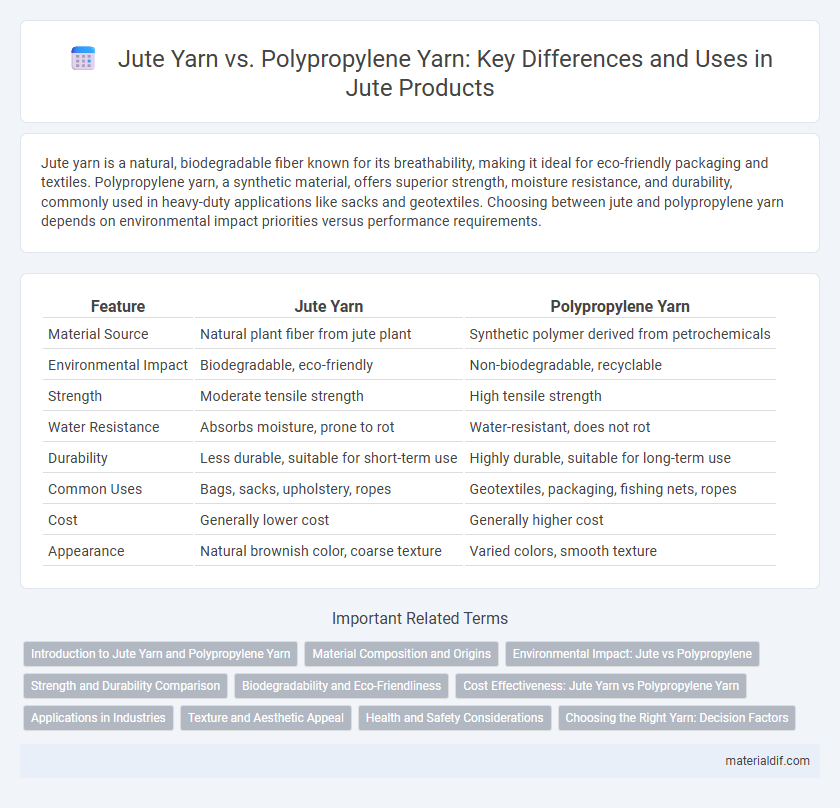

Table of Comparison

| Feature | Jute Yarn | Polypropylene Yarn |

|---|---|---|

| Material Source | Natural plant fiber from jute plant | Synthetic polymer derived from petrochemicals |

| Environmental Impact | Biodegradable, eco-friendly | Non-biodegradable, recyclable |

| Strength | Moderate tensile strength | High tensile strength |

| Water Resistance | Absorbs moisture, prone to rot | Water-resistant, does not rot |

| Durability | Less durable, suitable for short-term use | Highly durable, suitable for long-term use |

| Common Uses | Bags, sacks, upholstery, ropes | Geotextiles, packaging, fishing nets, ropes |

| Cost | Generally lower cost | Generally higher cost |

| Appearance | Natural brownish color, coarse texture | Varied colors, smooth texture |

Introduction to Jute Yarn and Polypropylene Yarn

Jute yarn, a natural fiber derived from the jute plant, is biodegradable, breathable, and widely used in eco-friendly packaging and textiles, offering strong tensile strength and moisture resistance. Polypropylene yarn, a synthetic polymer, is known for its durability, chemical resistance, and lightweight nature, commonly utilized in industrial applications such as geotextiles and rope manufacturing. Both yarns serve distinct purposes, with jute yarn favored for sustainable and biodegradable products while polypropylene yarn excels in high-performance, heavy-duty uses.

Material Composition and Origins

Jute yarn is derived from natural fibers obtained from the stalks of the Corchorus plant, predominantly cultivated in Bangladesh and India, making it biodegradable and eco-friendly. Polypropylene yarn, on the other hand, is a synthetic fiber produced from polymerized propylene derived from petroleum, characterized by its durability and resistance to moisture. The natural cellulose composition of jute contrasts with the petrochemical-based polypropylene, influencing their applications in textiles, packaging, and agriculture.

Environmental Impact: Jute vs Polypropylene

Jute yarn, a natural fiber derived from plants, is biodegradable and sustainable, significantly reducing environmental pollution compared to polypropylene yarn, which is a synthetic polymer made from non-renewable petroleum resources. The decomposition of jute yarn enriches the soil and lowers carbon footprint, while polypropylene yarn contributes to plastic pollution and persistence in ecosystems due to its non-biodegradable nature. Jute's eco-friendly characteristics make it a preferred choice for environmentally conscious textile and packaging industries.

Strength and Durability Comparison

Jute yarn offers moderate tensile strength and excellent biodegradability, making it suitable for eco-friendly applications but less durable under heavy mechanical stress compared to polypropylene yarn. Polypropylene yarn exhibits superior strength, resistance to abrasion, and durability, maintaining performance in harsh environmental conditions and prolonged use. The choice between jute and polypropylene yarn depends on balancing sustainability requirements with the need for high strength and long-lasting materials.

Biodegradability and Eco-Friendliness

Jute yarn is highly biodegradable, breaking down naturally within months, which significantly reduces environmental impact compared to polypropylene yarn that can persist for decades. The eco-friendliness of jute yarn stems from its renewable plant-based origins, requiring less energy and chemicals for production. In contrast, polypropylene yarn is derived from non-renewable petroleum, contributing to plastic pollution and slower decomposition rates.

Cost Effectiveness: Jute Yarn vs Polypropylene Yarn

Jute yarn is more cost-effective than polypropylene yarn due to its natural fiber properties and lower production expenses, making it ideal for eco-friendly and budget-conscious applications. Polypropylene yarn, while slightly more expensive, offers higher durability and resistance to moisture, impacting long-term cost savings in industrial uses. Evaluating total lifecycle costs reveals jute yarn's advantage in sustainable packaging, whereas polypropylene yarn suits heavy-duty requirements despite higher initial investment.

Applications in Industries

Jute yarn is widely used in eco-friendly packaging, agriculture, and textile industries due to its biodegradability and natural fiber properties, making it ideal for sacks, bags, and mats. Polypropylene yarn is preferred in industrial applications requiring high strength and durability, such as in geotextiles, ropes, and carpet backing, due to its resistance to moisture and chemical exposure. Industries aiming for sustainability often choose jute yarn, while those needing long-lasting performance under harsh conditions rely on polypropylene yarn.

Texture and Aesthetic Appeal

Jute yarn offers a coarse, natural texture with a matte finish, providing a rustic and eco-friendly aesthetic ideal for artisanal crafts and sustainable fashion. Polypropylene yarn features a smooth, synthetic texture with a shiny appearance, making it suitable for industrial applications and modern, vibrant designs. The tactile contrast between jute's roughness and polypropylene's slickness significantly influences their visual and sensory appeal in various product designs.

Health and Safety Considerations

Jute yarn is biodegradable, non-toxic, and free from harmful chemicals, making it a safer choice for health and environmentally friendly applications compared to polypropylene yarn, which is synthetic and can release microplastics contributing to pollution and respiratory issues. Jute fibers naturally resist bacterial growth, reducing the risk of skin irritation, whereas polypropylene yarn, being petroleum-based, may cause allergies or sensitivities in some individuals. Using jute yarn promotes safer manufacturing environments by minimizing exposure to synthetic chemicals and improving indoor air quality.

Choosing the Right Yarn: Decision Factors

Choosing between jute yarn and polypropylene yarn depends on factors such as environmental impact, durability, and cost-effectiveness. Jute yarn offers eco-friendly, biodegradable properties suitable for sustainable products, while polypropylene yarn provides higher strength and resistance to moisture, making it ideal for industrial applications. Consider the end-use requirements, including exposure to weather, load-bearing needs, and budget constraints, to select the appropriate yarn type.

Jute Yarn vs Polypropylene Yarn Infographic

materialdif.com

materialdif.com