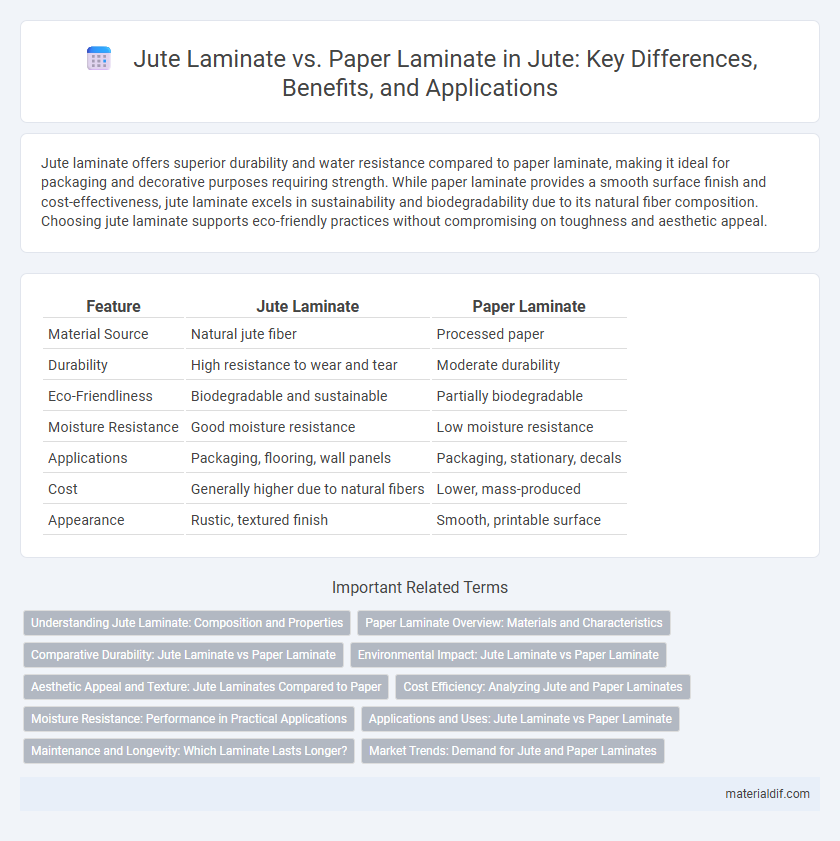

Jute laminate offers superior durability and water resistance compared to paper laminate, making it ideal for packaging and decorative purposes requiring strength. While paper laminate provides a smooth surface finish and cost-effectiveness, jute laminate excels in sustainability and biodegradability due to its natural fiber composition. Choosing jute laminate supports eco-friendly practices without compromising on toughness and aesthetic appeal.

Table of Comparison

| Feature | Jute Laminate | Paper Laminate |

|---|---|---|

| Material Source | Natural jute fiber | Processed paper |

| Durability | High resistance to wear and tear | Moderate durability |

| Eco-Friendliness | Biodegradable and sustainable | Partially biodegradable |

| Moisture Resistance | Good moisture resistance | Low moisture resistance |

| Applications | Packaging, flooring, wall panels | Packaging, stationary, decals |

| Cost | Generally higher due to natural fibers | Lower, mass-produced |

| Appearance | Rustic, textured finish | Smooth, printable surface |

Understanding Jute Laminate: Composition and Properties

Jute laminate consists of natural jute fibers combined with resin, creating a durable, eco-friendly composite known for its high tensile strength and biodegradability. Unlike paper laminate, jute laminate offers superior moisture resistance and enhanced structural integrity while maintaining lightweight characteristics. Its thermal insulation and acoustic properties make jute laminate ideal for sustainable packaging and interior design applications.

Paper Laminate Overview: Materials and Characteristics

Paper laminate consists of cellulose-based fibers derived from wood pulp, offering a smooth and printable surface ideal for packaging and labeling applications. Its lightweight nature and resistance to moisture make it a cost-effective solution for short to medium-term durability requirements. Compared to jute laminate, paper laminate provides enhanced aesthetics but lacks the natural strength and eco-friendliness associated with jute fibers.

Comparative Durability: Jute Laminate vs Paper Laminate

Jute laminate exhibits superior durability compared to paper laminate due to its natural fiber strength and resistance to tearing and moisture. While paper laminate is prone to wear and water damage, jute laminate offers enhanced longevity in high-traffic or humid environments. This makes jute laminate a more sustainable and resilient option for packaging and interior applications.

Environmental Impact: Jute Laminate vs Paper Laminate

Jute laminate exhibits significantly lower environmental impact than paper laminate due to its natural biodegradability and renewable sourcing from jute plants, which require minimal pesticides and water. Unlike paper laminate, which often involves chemically intensive processing and deforestation, jute laminate reduces carbon emissions and soil degradation. This sustainable advantage positions jute laminate as a superior choice for eco-conscious packaging and product manufacturing.

Aesthetic Appeal and Texture: Jute Laminates Compared to Paper

Jute laminates offer a natural, earthy aesthetic with a coarse texture that enhances rustic and organic design themes, contrasting sharply with the smooth, uniform surface of paper laminates. The woven fiber pattern in jute provides tactile depth and visual interest, making it ideal for applications seeking an authentic, handcrafted appearance. Paper laminates, while versatile and clean-looking, lack the textured richness and environmental appeal inherent to jute laminates.

Cost Efficiency: Analyzing Jute and Paper Laminates

Jute laminate offers superior cost efficiency compared to paper laminate due to its renewable fiber source and lower raw material expenses, reducing overall production costs. The durability and resistance to moisture of jute laminates extend product lifespan, minimizing replacement frequency and maintenance costs. In contrast, paper laminates often incur higher costs from synthetic coatings and shorter durability, impacting long-term investment value.

Moisture Resistance: Performance in Practical Applications

Jute laminate demonstrates superior moisture resistance compared to paper laminate, making it a preferred choice in environments prone to humidity and wet conditions. Its natural fibers combined with protective coatings prevent water absorption and maintain structural integrity over time. This enhanced durability ensures better performance in packaging, construction, and textile applications where moisture exposure is a critical factor.

Applications and Uses: Jute Laminate vs Paper Laminate

Jute laminate excels in eco-friendly packaging and sustainable construction materials due to its high tensile strength and natural biodegradability. Paper laminate is widely used in food packaging, printing industries, and decorative surfaces, offering flexibility and print clarity but lower durability compared to jute laminate. Industries focusing on environmental impact prefer jute laminate for reusable bags and insulation, while paper laminate caters to mass-market applications requiring cost efficiency and lightweight properties.

Maintenance and Longevity: Which Laminate Lasts Longer?

Jute laminate offers superior durability and requires less maintenance compared to paper laminate, thanks to its natural fibers' resistance to wear and tear. Paper laminate tends to degrade faster when exposed to moisture and frequent use, necessitating more frequent replacement or repairs. Choosing jute laminate ensures extended longevity and reduced upkeep, making it a cost-effective option for high-traffic or moisture-prone environments.

Market Trends: Demand for Jute and Paper Laminates

Rising environmental concerns drive increasing demand for jute laminate as a sustainable alternative to traditional paper laminate, which faces challenges due to limited biodegradability. Market trends indicate a surge in jute laminate adoption across packaging and automotive sectors, fueled by its strength, eco-friendliness, and cost-effectiveness. Meanwhile, paper laminate demand remains steady but grows slower, constrained by evolving regulatory standards favoring biodegradable and renewable materials.

Jute Laminate vs Paper Laminate Infographic

materialdif.com

materialdif.com