Jute roving offers a coarse texture and natural golden hue, making it ideal for rustic textiles and upholstery, while flax roving provides a finer, smoother fiber with superior strength suitable for high-quality linen fabrics. Flax roving's enhanced durability supports uses in technical textiles and composites, contrasting with jute's affordability and biodegradability favored in eco-friendly packaging and mats. Both fibers are plant-based and sustainable, but their differing physical properties determine their specific industrial applications.

Table of Comparison

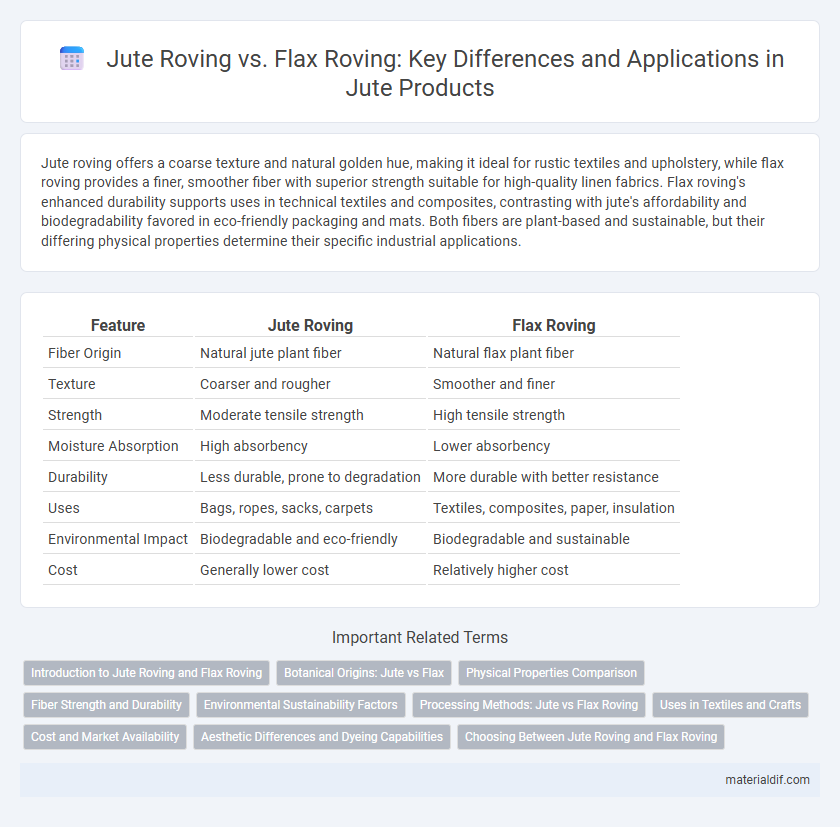

| Feature | Jute Roving | Flax Roving |

|---|---|---|

| Fiber Origin | Natural jute plant fiber | Natural flax plant fiber |

| Texture | Coarser and rougher | Smoother and finer |

| Strength | Moderate tensile strength | High tensile strength |

| Moisture Absorption | High absorbency | Lower absorbency |

| Durability | Less durable, prone to degradation | More durable with better resistance |

| Uses | Bags, ropes, sacks, carpets | Textiles, composites, paper, insulation |

| Environmental Impact | Biodegradable and eco-friendly | Biodegradable and sustainable |

| Cost | Generally lower cost | Relatively higher cost |

Introduction to Jute Roving and Flax Roving

Jute roving is a coarse, natural fiber bundle derived from the jute plant, primarily used in textiles, ropes, and composites due to its high tensile strength and biodegradability. Flax roving, extracted from the flax plant, offers finer fibers with excellent durability and moisture-wicking properties, commonly used in linen production and reinforced materials. Both jute and flax rovings serve as sustainable alternatives in eco-friendly manufacturing, distinguished by their fiber texture and strength characteristics.

Botanical Origins: Jute vs Flax

Jute roving is derived from the Corchorus plant species, primarily Corchorus olitorius and Corchorus capsularis, which thrive in tropical regions like India and Bangladesh. Flax roving comes from the Linum usitatissimum plant, a temperate climate fiber crop extensively cultivated in Europe and parts of North America. The botanical differences influence fiber properties, with jute fibers being coarser and lignin-rich, while flax fibers are finer and cellulose-dominant, affecting their respective industrial applications.

Physical Properties Comparison

Jute roving exhibits a coarser texture and higher tensile strength compared to flax roving, making it suitable for heavy-duty applications. Flax roving is finer and more flexible, offering superior softness and durability for textiles requiring smooth finishes. Both fibers differ in moisture absorbency, with flax roving possessing greater hygroscopic properties than jute roving, influencing their suitability in various industrial uses.

Fiber Strength and Durability

Jute roving exhibits moderate fiber strength with tensile properties suitable for lightweight and flexible applications, while flax roving offers superior fiber strength and durability due to its longer and more lignified fibers. Flax fibers provide enhanced resistance to wear and environmental factors, making flax roving ideal for high-stress textile products, whereas jute roving is preferred for eco-friendly, cost-effective uses with moderate durability requirements. The inherent mechanical properties of flax ensure greater longevity and robustness compared to jute in industrial and composite material contexts.

Environmental Sustainability Factors

Jute roving exhibits superior environmental sustainability compared to flax roving due to its rapid growth rate and low requirements for pesticides and fertilizers. The biodegradability and carbon sequestration potential of jute fibers contribute to reduced ecological footprints in textile production. Moreover, jute cultivation enhances soil fertility and supports biodiversity, making it a more eco-friendly option than flax in sustainable fiber industries.

Processing Methods: Jute vs Flax Roving

Jute roving undergoes a retting process followed by cleaning and combing to align fibers for spinning, emphasizing moisture retention and durability. Flax roving is produced through dew retting, scutching, and hackling, which refine fibers to achieve smoother and finer strands ideal for linen production. The difference in processing methods results in jute's coarser texture, suited for burlap and sacks, whereas flax's finer fibers cater to high-quality textiles.

Uses in Textiles and Crafts

Jute roving is primarily used in coarse textiles, sacks, and carpets due to its strong, coarse fibers that provide durability and resistance to wear. Flax roving, prized for its smooth, fine fibers, is favored in high-quality linen fabrics, fine garments, and delicate crafts requiring softness and luster. Both fibers serve distinct roles in textile production, with jute suited for heavy-duty applications and flax preferred for fine, lightweight materials.

Cost and Market Availability

Jute roving is generally more cost-effective than flax roving due to the abundant cultivation of jute in South Asia, driving widespread market availability and lower prices. Flax roving, derived from flax plants primarily grown in Europe and North America, tends to be pricier, reflecting limited production regions and higher processing expenses. The global market for jute roving is expansive and more accessible, making it a preferred choice in budget-sensitive applications.

Aesthetic Differences and Dyeing Capabilities

Jute roving exhibits a naturally coarse texture with a warm, golden-brown hue, creating a rustic aesthetic ideal for earthy and traditional textile designs, while flax roving offers a smoother, finer fiber with a light beige color, lending itself to more refined and delicate fabric appearances. In terms of dyeing capabilities, flax roving absorbs dyes uniformly and holds vibrant colors well due to its smooth surface, resulting in bright, consistent hues; conversely, jute roving's coarse texture and natural pigmentation cause a more subdued dye uptake, producing muted tones and a unique, variegated color effect. These inherent differences make jute roving preferable for organic, textured projects and flax roving suitable for precision-colored, polished textile applications.

Choosing Between Jute Roving and Flax Roving

Choosing between jute roving and flax roving largely depends on the desired fiber strength and application. Jute roving offers coarser, more affordable fibers ideal for packaging and coarse textiles, while flax roving provides finer, stronger fibers suited for high-quality linen and composite materials. Evaluating factors such as tensile strength, fiber fineness, and environmental impact ensures optimal selection for industrial or craft uses.

Jute Roving vs Flax Roving Infographic

materialdif.com

materialdif.com