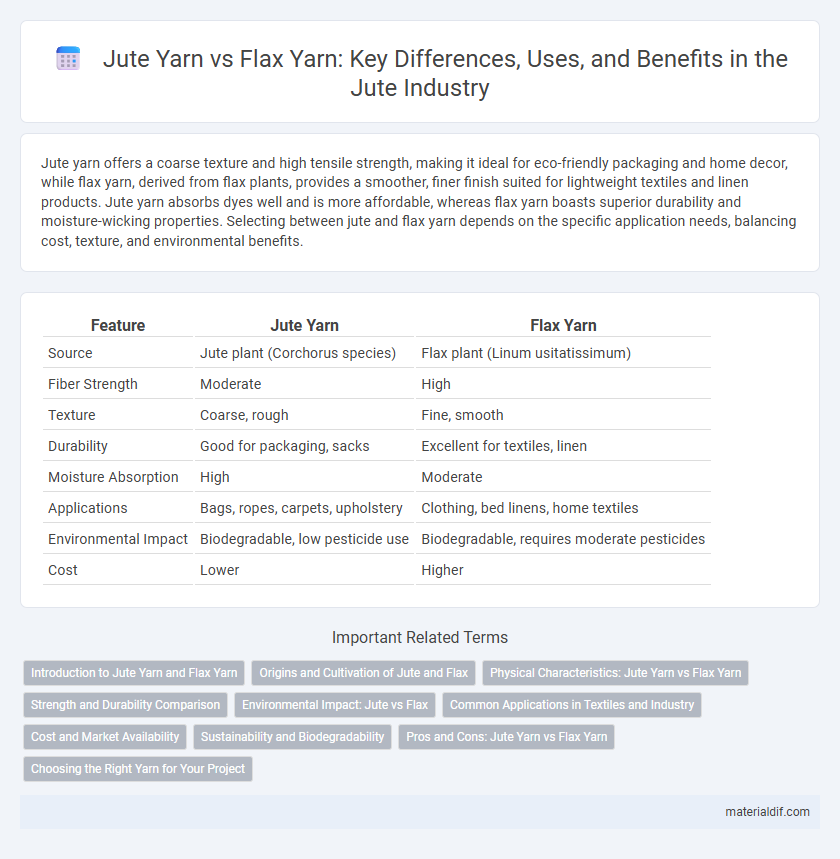

Jute yarn offers a coarse texture and high tensile strength, making it ideal for eco-friendly packaging and home decor, while flax yarn, derived from flax plants, provides a smoother, finer finish suited for lightweight textiles and linen products. Jute yarn absorbs dyes well and is more affordable, whereas flax yarn boasts superior durability and moisture-wicking properties. Selecting between jute and flax yarn depends on the specific application needs, balancing cost, texture, and environmental benefits.

Table of Comparison

| Feature | Jute Yarn | Flax Yarn |

|---|---|---|

| Source | Jute plant (Corchorus species) | Flax plant (Linum usitatissimum) |

| Fiber Strength | Moderate | High |

| Texture | Coarse, rough | Fine, smooth |

| Durability | Good for packaging, sacks | Excellent for textiles, linen |

| Moisture Absorption | High | Moderate |

| Applications | Bags, ropes, carpets, upholstery | Clothing, bed linens, home textiles |

| Environmental Impact | Biodegradable, low pesticide use | Biodegradable, requires moderate pesticides |

| Cost | Lower | Higher |

Introduction to Jute Yarn and Flax Yarn

Jute yarn is a natural fiber extracted from the bark of the jute plant, known for its coarse texture, durability, and biodegradability, making it ideal for sacks, rugs, and upholstery. Flax yarn, derived from the flax plant, features finer, stronger fibers with a smooth texture, commonly used in linen textiles and high-quality fabrics. Both yarns serve distinct industrial and textile applications due to their unique fiber properties and environmental benefits.

Origins and Cultivation of Jute and Flax

Jute yarn is derived from the stem fibers of the Corchorus plant, predominantly cultivated in the warm, humid regions of India and Bangladesh, where rich alluvial soil and monsoon climate favor its growth. Flax yarn originates from the flax plant, primarily grown in temperate climates such as Western Europe and Canada, requiring well-drained, fertile soil and cooler temperatures for optimal fiber quality. The distinct environmental conditions and soil preferences of jute and flax cultivation significantly influence the texture and strength of their respective yarns.

Physical Characteristics: Jute Yarn vs Flax Yarn

Jute yarn exhibits a coarser texture with lower tensile strength, making it less smooth and more prone to abrasion compared to flax yarn. Flax yarn is finer, stronger, and has a lustrous appearance due to its long, smooth fibers that enhance durability. Both fibers are biodegradable and environmentally friendly, but flax yarn's superior strength and softness make it ideal for textiles requiring finer quality and resilience.

Strength and Durability Comparison

Jute yarn exhibits moderate strength and durability, making it suitable for applications like sacks and mats where flexibility is essential but extreme tensile strength is not critical. Flax yarn, derived from flax fibers, is significantly stronger and more durable, often used in textiles requiring higher resistance to wear and tear. The higher cellulose content and tightly packed fibers of flax result in better tensile strength and longevity compared to jute yarn.

Environmental Impact: Jute vs Flax

Jute yarn has a lower environmental impact than flax yarn due to its rapid growth cycle, requiring less water and fewer pesticides during cultivation. Flax, used to produce linen, demands more intensive agricultural inputs including significant irrigation and chemical treatments, which can contribute to soil degradation and water pollution. Both fibers are biodegradable and renewable, but jute's minimal resource requirements and carbon sequestration potential make it a more sustainable choice for eco-friendly textiles.

Common Applications in Textiles and Industry

Jute yarn is widely used for making sacks, ropes, carpets, and upholstery due to its durability and coarse texture, making it ideal for heavy-duty industrial applications. Flax yarn, derived from flax fibers, finds common applications in high-quality linen textiles, fashion garments, and home furnishings because of its smoothness and strength. Both fibers serve distinct roles in textiles, with jute favored for rougher, sustainable products, while flax caters to finer, breathable materials in clothing and interior design.

Cost and Market Availability

Jute yarn generally offers a lower cost compared to flax yarn, making it a preferred choice for budget-sensitive applications. The market availability of jute yarn is higher due to its widespread cultivation in countries like India and Bangladesh, ensuring steady supply. Flax yarn, derived from flax plants primarily grown in Europe and North America, tends to be more expensive and less readily available in global markets.

Sustainability and Biodegradability

Jute yarn is highly sustainable, derived from the Corchorus plant which requires minimal pesticides and water, making it an eco-friendly alternative to synthetic fibers. Flax yarn, sourced from the flax plant, is also biodegradable and sustainable, but it generally demands more intensive agricultural inputs and water usage compared to jute. Both fibers offer excellent biodegradability, decomposing naturally within months, yet jute's lower environmental footprint during cultivation positions it as a more sustainable choice in textile production.

Pros and Cons: Jute Yarn vs Flax Yarn

Jute yarn offers affordability and durability, making it ideal for packaging and agricultural uses, but it tends to be coarse and less flexible compared to flax yarn. Flax yarn, derived from flax fibers, provides superior strength, softness, and moisture-wicking properties, suitable for high-quality textiles and clothing, yet it comes at a higher cost and requires more intensive processing. While jute excels in eco-friendliness and biodegradability, flax yarn offers enhanced comfort and longevity, influencing the choice based on specific application needs.

Choosing the Right Yarn for Your Project

Jute yarn offers durability and a coarse texture ideal for rustic crafts, upholstery, and eco-friendly products, while flax yarn provides a smoother, stronger fiber favored for fine textiles and garments. When choosing between jute and flax yarn, consider the desired fabric strength, texture, and end-use requirements, as flax yarn excels in softness and moisture absorption, whereas jute yarn supports heavier, more rugged applications. Selecting the appropriate yarn depends on balancing these fiber characteristics with your project's functional and aesthetic goals.

Jute Yarn vs Flax Yarn Infographic

materialdif.com

materialdif.com