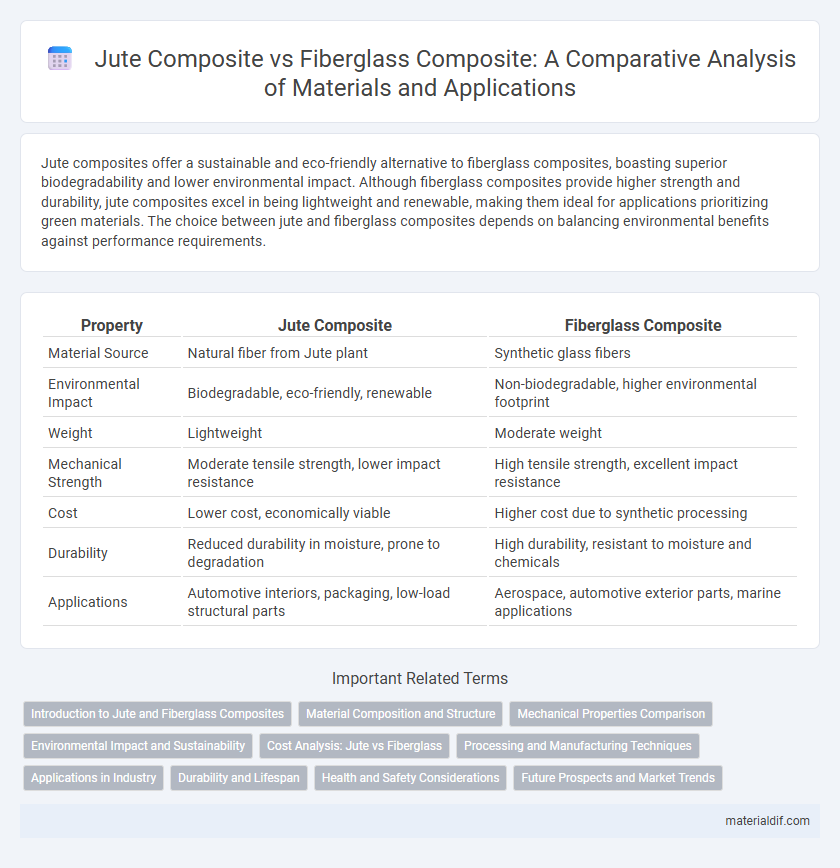

Jute composites offer a sustainable and eco-friendly alternative to fiberglass composites, boasting superior biodegradability and lower environmental impact. Although fiberglass composites provide higher strength and durability, jute composites excel in being lightweight and renewable, making them ideal for applications prioritizing green materials. The choice between jute and fiberglass composites depends on balancing environmental benefits against performance requirements.

Table of Comparison

| Property | Jute Composite | Fiberglass Composite |

|---|---|---|

| Material Source | Natural fiber from Jute plant | Synthetic glass fibers |

| Environmental Impact | Biodegradable, eco-friendly, renewable | Non-biodegradable, higher environmental footprint |

| Weight | Lightweight | Moderate weight |

| Mechanical Strength | Moderate tensile strength, lower impact resistance | High tensile strength, excellent impact resistance |

| Cost | Lower cost, economically viable | Higher cost due to synthetic processing |

| Durability | Reduced durability in moisture, prone to degradation | High durability, resistant to moisture and chemicals |

| Applications | Automotive interiors, packaging, low-load structural parts | Aerospace, automotive exterior parts, marine applications |

Introduction to Jute and Fiberglass Composites

Jute composites are made from natural jute fibers combined with a polymer matrix, offering eco-friendly and biodegradable alternatives to traditional materials. Fiberglass composites consist of glass fibers embedded in a resin matrix, known for their high strength, durability, and resistance to corrosion. While jute composites provide lightweight and sustainable solutions, fiberglass composites excel in applications requiring superior mechanical properties and long-term performance.

Material Composition and Structure

Jute composite consists of natural jute fibers embedded in a biodegradable polymer matrix, offering a lightweight and eco-friendly alternative to fiberglass composites, which are made of glass fibers reinforced with a thermoset or thermoplastic resin. The cellulose-rich jute fibers provide excellent tensile strength and flexibility, while fiberglass composites deliver superior mechanical strength and resistance to heat and chemicals due to their inorganic glass fiber structure. Material composition in jute composites results in better biodegradability and lower environmental impact, whereas fiberglass composites excel in durability and structural integrity for heavy-duty applications.

Mechanical Properties Comparison

Jute composites exhibit lower tensile strength and impact resistance compared to fiberglass composites, but offer superior biodegradability and lighter weight. Fiberglass composites provide higher flexural and shear strength, making them more suitable for high-load structural applications. Jute composites' mechanical properties vary with fiber treatment and resin type, offering a sustainable alternative with moderate durability.

Environmental Impact and Sustainability

Jute composite materials offer significantly lower environmental impact compared to fiberglass composites, primarily due to their biodegradability and renewable sourcing from jute plants. The production of jute composites consumes less energy and generates fewer carbon emissions, making them a sustainable alternative in reducing ecological footprints. Unlike fiberglass, jute composites decompose naturally without releasing harmful microplastics, contributing to reduced long-term environmental pollution.

Cost Analysis: Jute vs Fiberglass

Jute composites offer a significantly lower material cost compared to fiberglass composites, making them an economical choice for sustainable product manufacturing. The processing and labor expenses for jute composites are also reduced due to simpler fabrication techniques and lower energy requirements. Despite a modest compromise in mechanical strength, the cost-efficiency of jute composites makes them ideal for applications prioritizing affordability and environmental benefits over performance.

Processing and Manufacturing Techniques

Jute composites are typically processed using eco-friendly methods such as hand lay-up, compression molding, and resin transfer molding, which require lower energy and enable better biodegradability compared to fiberglass composites. Fiberglass composite manufacturing relies heavily on energy-intensive processes like filament winding, spray-up, and pultrusion, often involving synthetic resins that extend environmental impact. The natural fiber structure of jute allows for easier treatment and compatibility with bio-based resins, enhancing sustainability and reducing overall production costs relative to fiberglass composites.

Applications in Industry

Jute composites offer sustainable advantages in automotive interiors, packaging, and construction panels due to their biodegradability and lightweight nature. Fiberglass composites dominate in aerospace, marine, and high-performance sports equipment industries because of their superior strength, durability, and resistance to moisture. Industrial applications increasingly prefer jute composites for eco-friendly alternatives, while fiberglass remains essential for durability-demanding uses.

Durability and Lifespan

Jute composites offer moderate durability with biodegradability but exhibit lower resistance to moisture and UV degradation compared to fiberglass composites, which provide superior strength and long-lasting performance in harsh environments. Fiberglass composites maintain structural integrity for 20-30 years under outdoor conditions, while jute composites typically last around 5-10 years depending on treatment and application. Moisture absorption and susceptibility to biological decay limit the lifespan of jute composites, making fiberglass the preferred choice for high-stress, long-term use.

Health and Safety Considerations

Jute composite materials offer significant health and safety advantages over fiberglass composites, as jute fibers are natural, biodegradable, and non-toxic, reducing the risk of respiratory irritation and skin sensitization during handling and processing. Unlike fiberglass, which can release fine glass dust and cause allergic reactions or lung issues, jute composites pose minimal airborne particulate hazards, enhancing workplace safety. Furthermore, jute composites contribute to a healthier indoor environment by avoiding the off-gassing of harmful volatile organic compounds (VOCs) commonly associated with synthetic composites.

Future Prospects and Market Trends

Jute composite materials are gaining traction due to their sustainable attributes, biodegradability, and cost-effectiveness, appealing to eco-conscious markets that prioritize renewable resources. Fiberglass composites continue to dominate high-performance applications because of their superior strength and durability, but rising environmental regulations are encouraging industry shifts towards natural fiber alternatives like jute. Future market trends indicate a growing preference for hybrid composites combining jute and fiberglass to balance mechanical properties with ecological benefits in automotive and construction sectors.

Jute Composite vs Fiberglass Composite Infographic

materialdif.com

materialdif.com