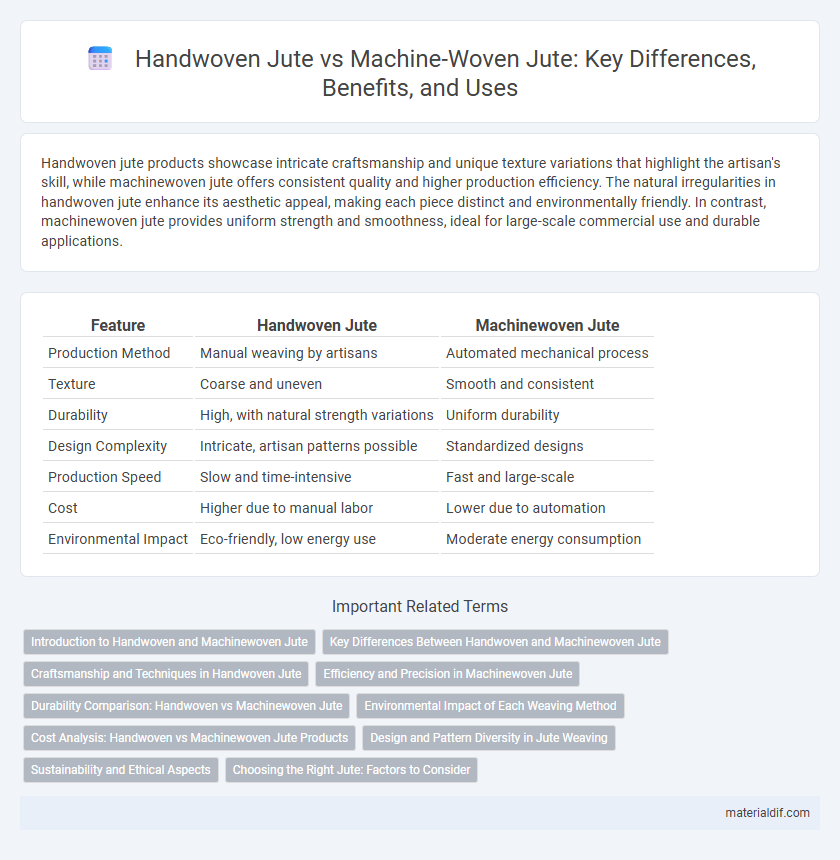

Handwoven jute products showcase intricate craftsmanship and unique texture variations that highlight the artisan's skill, while machinewoven jute offers consistent quality and higher production efficiency. The natural irregularities in handwoven jute enhance its aesthetic appeal, making each piece distinct and environmentally friendly. In contrast, machinewoven jute provides uniform strength and smoothness, ideal for large-scale commercial use and durable applications.

Table of Comparison

| Feature | Handwoven Jute | Machinewoven Jute |

|---|---|---|

| Production Method | Manual weaving by artisans | Automated mechanical process |

| Texture | Coarse and uneven | Smooth and consistent |

| Durability | High, with natural strength variations | Uniform durability |

| Design Complexity | Intricate, artisan patterns possible | Standardized designs |

| Production Speed | Slow and time-intensive | Fast and large-scale |

| Cost | Higher due to manual labor | Lower due to automation |

| Environmental Impact | Eco-friendly, low energy use | Moderate energy consumption |

Introduction to Handwoven and Machinewoven Jute

Handwoven jute is crafted using traditional manual techniques that emphasize intricate patterns and superior texture, resulting in unique and artisanal fabric quality. Machinewoven jute utilizes automated looms for faster production, offering consistent weave strength and uniformity in large-scale manufacturing. Both methods impact the durability, appearance, and price of jute products, with handwoven jute being more labor-intensive and machinewoven jute catering to mass-market demands.

Key Differences Between Handwoven and Machinewoven Jute

Handwoven jute features unique texture variations and irregularities, reflecting skilled craftsmanship and traditional techniques, while machinewoven jute exhibits uniform consistency and precise patterns due to mechanized production. The durability of handwoven jute tends to be higher in artisan products, as the weaving density can be tightly controlled by the weavers, whereas machinewoven jute often allows for faster production and cost efficiency. Environmental impact of handwoven jute is generally lower owing to minimal energy consumption, contrasting with the higher energy use and emissions associated with machine weaving processes.

Craftsmanship and Techniques in Handwoven Jute

Handwoven jute showcases intricate craftsmanship, where artisans employ traditional techniques such as hand spinning and weaving on manual looms, resulting in unique textures and superior durability. Unlike machinewoven jute, which relies on automated processes for uniformity and speed, handwoven jute emphasizes artisanal skill, allowing for subtle variations and complex patterns that reflect cultural heritage. The meticulous attention to thread tension, dye application, and weaving patterns in handwoven jute produces high-quality fabrics prized for their authenticity and aesthetic richness.

Efficiency and Precision in Machinewoven Jute

Machinewoven jute offers superior efficiency and precision compared to handwoven jute, enabling faster production rates and consistent fabric quality. Advanced mechanical looms ensure uniform thread tension and intricate pattern accuracy, which is challenging to achieve manually. This results in machinewoven jute being ideal for large-scale manufacturing and applications requiring standardized dimensions and durability.

Durability Comparison: Handwoven vs Machinewoven Jute

Handwoven jute products typically exhibit higher durability due to the meticulous craftsmanship and tighter fiber integration, enhancing their strength and lifespan. Machinewoven jute, while produced faster and more uniformly, may have lower tensile strength because mechanical processes can create weaker fiber bonds. Studies show handwoven jute maintains structural integrity better under stress, making it preferable for long-lasting applications in home decor and packaging.

Environmental Impact of Each Weaving Method

Handwoven jute typically has a lower environmental impact than machinewoven jute due to its reliance on manual labor, which reduces energy consumption and carbon emissions. The handweaving process produces minimal waste and supports sustainable practices by preserving traditional methods without industrial-scale resource usage. Machinewoven jute, while efficient and cost-effective, generally involves higher electricity consumption and greater greenhouse gas emissions, contributing to a larger carbon footprint in production.

Cost Analysis: Handwoven vs Machinewoven Jute Products

Handwoven jute products typically incur higher labor costs due to the skill-intensive and time-consuming process, resulting in premium pricing compared to machinewoven alternatives. Machinewoven jute products benefit from automated production lines, reducing manufacturing time and overall expenses, making them more cost-effective for large-scale orders. The choice between handwoven and machinewoven jute ultimately hinges on balancing artisanal value and budget constraints in product sourcing.

Design and Pattern Diversity in Jute Weaving

Handwoven jute showcases intricate, unique patterns reflecting traditional craftsmanship and cultural heritage, often featuring variations that machinewoven jute cannot replicate. Machinewoven jute offers consistent, uniform designs with greater efficiency but lacks the artisanal diversity found in handwoven textiles. The choice between handwoven and machinewoven jute significantly impacts the design complexity and aesthetic appeal of jute products.

Sustainability and Ethical Aspects

Handwoven jute employs traditional artisan techniques that reduce energy consumption and support local economies, promoting sustainable and ethical production. Machinewoven jute offers higher efficiency but often relies on industrial processes that increase carbon emissions and diminish the social impact on artisan communities. Choosing handwoven jute aligns with eco-friendly values and fair trade principles, fostering environmental stewardship and improving livelihoods for rural artisans.

Choosing the Right Jute: Factors to Consider

Handwoven jute offers unique texture and durability due to traditional craftsmanship, making it ideal for artisanal products and eco-friendly interiors. Machinewoven jute provides consistent quality, uniform patterns, and cost-effective production suitable for large-scale manufacturing and commercial use. Consider factors such as desired texture, production volume, budget constraints, and aesthetic preferences when choosing between handwoven and machinewoven jute.

Handwoven Jute vs Machinewoven Jute Infographic

materialdif.com

materialdif.com