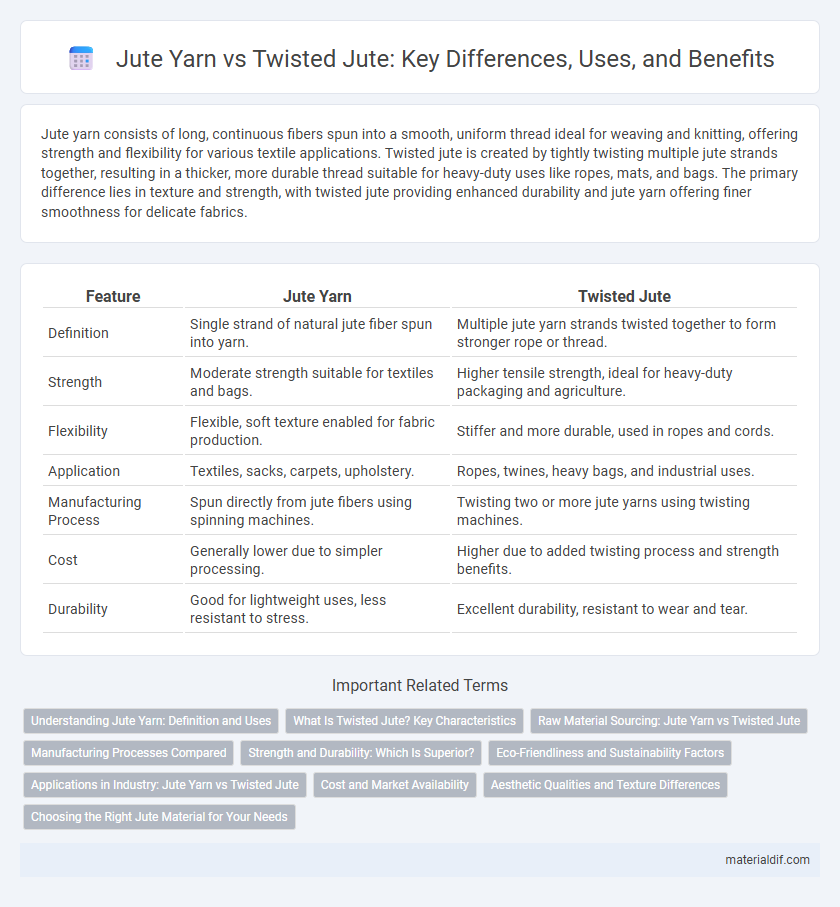

Jute yarn consists of long, continuous fibers spun into a smooth, uniform thread ideal for weaving and knitting, offering strength and flexibility for various textile applications. Twisted jute is created by tightly twisting multiple jute strands together, resulting in a thicker, more durable thread suitable for heavy-duty uses like ropes, mats, and bags. The primary difference lies in texture and strength, with twisted jute providing enhanced durability and jute yarn offering finer smoothness for delicate fabrics.

Table of Comparison

| Feature | Jute Yarn | Twisted Jute |

|---|---|---|

| Definition | Single strand of natural jute fiber spun into yarn. | Multiple jute yarn strands twisted together to form stronger rope or thread. |

| Strength | Moderate strength suitable for textiles and bags. | Higher tensile strength, ideal for heavy-duty packaging and agriculture. |

| Flexibility | Flexible, soft texture enabled for fabric production. | Stiffer and more durable, used in ropes and cords. |

| Application | Textiles, sacks, carpets, upholstery. | Ropes, twines, heavy bags, and industrial uses. |

| Manufacturing Process | Spun directly from jute fibers using spinning machines. | Twisting two or more jute yarns using twisting machines. |

| Cost | Generally lower due to simpler processing. | Higher due to added twisting process and strength benefits. |

| Durability | Good for lightweight uses, less resistant to stress. | Excellent durability, resistant to wear and tear. |

Understanding Jute Yarn: Definition and Uses

Jute yarn, derived from natural jute fibers, is a soft, strong, and versatile thread commonly used in textiles, bags, and crafting due to its durability and eco-friendly properties. Twisted jute involves intertwining multiple jute yarn strands to enhance strength and create a firmer texture, making it ideal for ropes, mats, and heavy-duty packaging. Understanding the differences in structure and strength between jute yarn and twisted jute is crucial for selecting the appropriate material in various industrial and artisanal applications.

What Is Twisted Jute? Key Characteristics

Twisted jute is yarn that has been spun by twisting multiple jute fibers together, enhancing its strength and durability compared to regular jute yarn. Key characteristics include increased tensile strength, improved resistance to wear and tear, and a rougher texture, making it suitable for ropes, mats, and heavy-duty packaging materials. This twist also provides better structural integrity, ensuring longer-lasting performance in industrial and agricultural applications.

Raw Material Sourcing: Jute Yarn vs Twisted Jute

Jute yarn is primarily made from raw jute fibers that undergo a spinning process to create continuous strands, while twisted jute involves twisting multiple jute yarns together to enhance strength and texture. Raw material sourcing for both begins with long, high-quality jute stalks harvested mainly in regions such as Bangladesh, India, and China, where optimal climate conditions support fiber quality. The choice between jute yarn and twisted jute depends on the grade and processing of raw jute, impacting durability and application in textiles and packaging industries.

Manufacturing Processes Compared

Jute yarn is produced by spinning raw jute fibers into continuous threads using traditional spinning machines, emphasizing fiber alignment and uniformity. Twisted jute involves an additional step where multiple jute yarns are tightly twisted together to enhance strength and durability, often using specialized twisting machines for consistent tension. The primary manufacturing difference lies in the twisting process, which imparts greater tensile strength and flexibility to twisted jute compared to standard jute yarn.

Strength and Durability: Which Is Superior?

Jute yarn, made from raw jute fibers, offers natural strength and moderate durability suitable for lightweight applications, while twisted jute enhances tensile strength and durability due to its tightly spun fibers, making it more resistant to wear and tear. The twisting process aligns fibers closely, reducing fiber breakage and increasing overall longevity compared to regular jute yarn. Therefore, twisted jute is superior in strength and durability, ideal for heavy-duty products like ropes and sacks.

Eco-Friendliness and Sustainability Factors

Jute yarn and twisted jute both offer eco-friendly and sustainable solutions due to their biodegradable nature and low environmental impact during production. Jute yarn, being a natural fiber spun without chemical treatments, maintains higher biodegradability and minimal carbon footprint compared to synthetic alternatives. Twisted jute enhances durability and strength for industrial uses while still preserving jute's inherent sustainability advantages, making both suitable for green manufacturing and eco-conscious markets.

Applications in Industry: Jute Yarn vs Twisted Jute

Jute yarn is extensively used in textile industries for making coarse fabrics, sacks, and bags due to its high tensile strength and natural absorbency. Twisted jute, with its enhanced durability and flexibility, is preferred in rope-making, upholstery, and carpet manufacturing where resistance to wear and tear is critical. Both variants contribute significantly to eco-friendly packaging and agricultural products, supporting sustainable industrial practices.

Cost and Market Availability

Jute yarn is generally more affordable than twisted jute due to simpler manufacturing processes and widespread production, making it highly accessible in global markets. Twisted jute, with enhanced strength and durability, commands a higher price and is available primarily through specialized suppliers targeting industrial and artisanal applications. Market availability of jute yarn supports bulk demand in textiles and packaging, whereas twisted jute caters to niche segments requiring reinforced fiber solutions.

Aesthetic Qualities and Texture Differences

Jute yarn features a smooth, uniform texture that enhances the natural sheen and earthy tones, ideal for refined, aesthetic applications in textiles and decor. Twisted jute, created by intertwining multiple jute strands, offers a rougher, more textured surface that adds rustic charm and durability to crafts and upholstery. The contrast in texture between smooth jute yarn and rugged twisted jute significantly influences their visual appeal and tactile experience in various uses.

Choosing the Right Jute Material for Your Needs

Jute yarn offers a smooth, consistent texture ideal for fine weaving and delicate crafts, while twisted jute provides enhanced strength and durability suited for heavy-duty applications like ropes and sacks. Selecting the right jute material depends on the intended use--choose jute yarn for lightweight, decorative projects and twisted jute for robust, load-bearing tasks. Understanding these differences ensures optimal performance and longevity in your jute-based products.

Jute Yarn vs Twisted Jute Infographic

materialdif.com

materialdif.com