Jute webbing offers an eco-friendly, biodegradable alternative to synthetic webbing, making it ideal for sustainable pet products. It provides natural durability and breathability, reducing the risk of irritation for pets compared to some synthetic materials. While synthetic webbing tends to be more resistant to water and wear, jute webbing stands out for its environmental benefits and comfort.

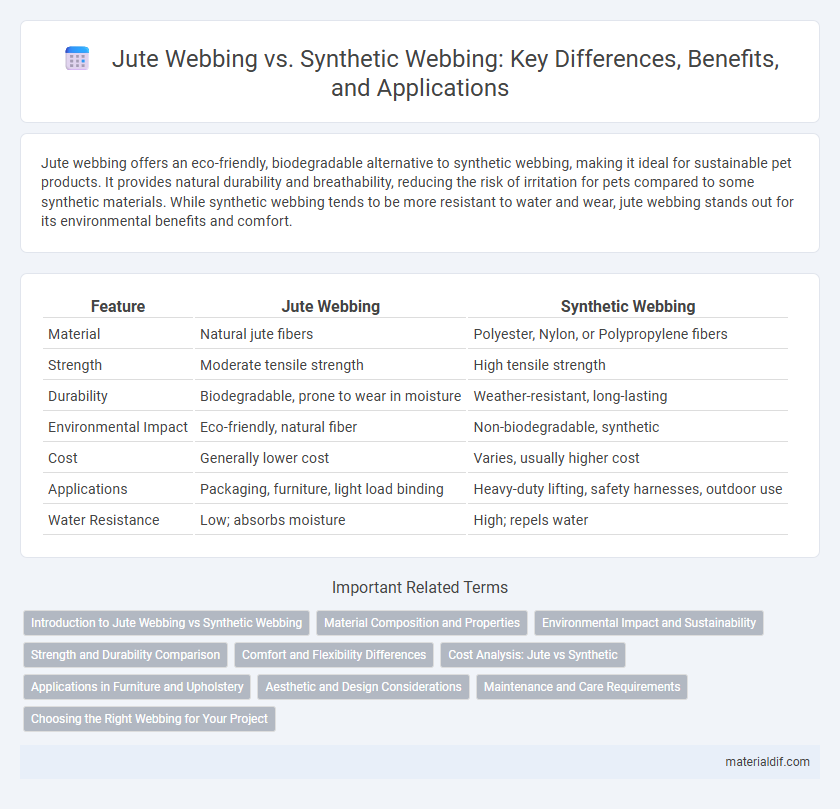

Table of Comparison

| Feature | Jute Webbing | Synthetic Webbing |

|---|---|---|

| Material | Natural jute fibers | Polyester, Nylon, or Polypropylene fibers |

| Strength | Moderate tensile strength | High tensile strength |

| Durability | Biodegradable, prone to wear in moisture | Weather-resistant, long-lasting |

| Environmental Impact | Eco-friendly, natural fiber | Non-biodegradable, synthetic |

| Cost | Generally lower cost | Varies, usually higher cost |

| Applications | Packaging, furniture, light load binding | Heavy-duty lifting, safety harnesses, outdoor use |

| Water Resistance | Low; absorbs moisture | High; repels water |

Introduction to Jute Webbing vs Synthetic Webbing

Jute webbing, derived from natural plant fibers, offers eco-friendly, biodegradable strength ideal for sustainable applications, while synthetic webbing, made from materials like nylon or polyester, provides superior durability, elasticity, and resistance to abrasion and moisture. Jute webbing excels in environments requiring low environmental impact and natural aesthetics, whereas synthetic webbing is preferred in heavy-duty, high-stress conditions demanding greater tensile strength and longevity. Understanding the contrasting properties of jute and synthetic webbings is essential for selecting the appropriate material in packaging, upholstery, and industrial uses.

Material Composition and Properties

Jute webbing is made from natural vegetable fibers derived from the jute plant, offering biodegradability and breathability, while synthetic webbing is produced from petroleum-based polymers such as nylon or polyester, providing superior strength and resistance to moisture and abrasion. The natural composition of jute results in lower tensile strength and susceptibility to mildew, whereas synthetic webbing exhibits enhanced durability, UV resistance, and greater load-bearing capacity. Selecting between jute and synthetic webbing depends on application-specific requirements for environmental impact, strength, and longevity.

Environmental Impact and Sustainability

Jute webbing offers a significantly lower environmental impact compared to synthetic webbing due to its biodegradable nature and renewable sources. Cultivating jute requires minimal pesticides and fertilizers, enhancing soil health and reducing pollution. Synthetic webbing, made from petroleum-based materials, contributes to microplastic pollution and has a higher carbon footprint throughout its lifecycle.

Strength and Durability Comparison

Jute webbing offers moderate tensile strength suitable for light to medium-duty applications, with natural fibers providing decent abrasion resistance but limited resistance to moisture and UV exposure. Synthetic webbing, typically made from materials like nylon or polyester, exhibits superior strength, higher tensile load capacity, and enhanced durability under harsh environmental conditions, including resistance to mildew, UV degradation, and chemical exposure. Choosing synthetic webbing ensures longer-lasting performance for heavy-duty use, while jute webbing remains a biodegradable and eco-friendly option with reasonable strength for less demanding tasks.

Comfort and Flexibility Differences

Jute webbing offers superior breathability and natural softness, enhancing comfort during prolonged use, while synthetic webbing tends to be stiffer and less breathable, potentially causing discomfort. The natural fibers in jute provide greater flexibility, allowing the webbing to conform more easily to irregular shapes, whereas synthetic webbing often maintains a rigid structure that limits adaptability. Comfort and flexibility differences make jute webbing ideal for applications requiring natural cushioning and movement, contrasting with synthetic webbing's durability focus.

Cost Analysis: Jute vs Synthetic

Jute webbing typically offers a lower initial cost due to its natural fibers and simpler manufacturing process compared to synthetic webbing, which relies on petroleum-based materials and advanced production techniques. Over time, synthetic webbing may incur higher upfront expenses but provides greater durability, reducing replacement frequency and maintenance costs. Evaluating cost efficiency requires balancing jute's affordability against synthetic webbing's extended lifespan and resistance to environmental factors.

Applications in Furniture and Upholstery

Jute webbing offers natural breathability and eco-friendly durability, making it ideal for traditional and vintage furniture upholstery, where sustainable material choices are prioritized. Synthetic webbing, typically made from polyester or nylon, provides superior strength and resistance to stretching, well-suited for modern furniture requiring high load support and long-lasting performance. Both materials are valued in upholstery, with jute favored for its biodegradable properties and synthetic webbing preferred for heavy-duty applications.

Aesthetic and Design Considerations

Jute webbing offers a natural, rustic aesthetic with its coarse texture and earthy tones, making it ideal for eco-friendly and vintage-inspired designs. Synthetic webbing provides a smooth, uniform appearance available in a wide range of colors and patterns, allowing for greater versatility in modern and vibrant design applications. Designers often choose jute for organic authenticity, while synthetic webbing suits sleek, contemporary styles requiring durability and color consistency.

Maintenance and Care Requirements

Jute webbing requires less frequent washing and is prone to natural fiber degradation, necessitating careful drying to prevent mold and mildew. Synthetic webbing tolerates regular machine washing, resists moisture-related damage, and is more durable under heavy use. Proper maintenance of jute webbing involves gentle cleaning and avoiding prolonged exposure to water, while synthetic webbing benefits from its resistance to chemicals and UV rays for extended longevity.

Choosing the Right Webbing for Your Project

Jute webbing offers a natural, biodegradable option with strong tensile strength ideal for eco-friendly projects requiring durability and breathability. Synthetic webbing, made from materials like nylon or polyester, provides superior resistance to moisture, UV rays, and abrasion, making it suitable for heavy-duty or outdoor applications. Selecting the right webbing depends on project requirements such as environmental impact, strength, weather resistance, and budget constraints.

Jute Webbing vs Synthetic Webbing Infographic

materialdif.com

materialdif.com