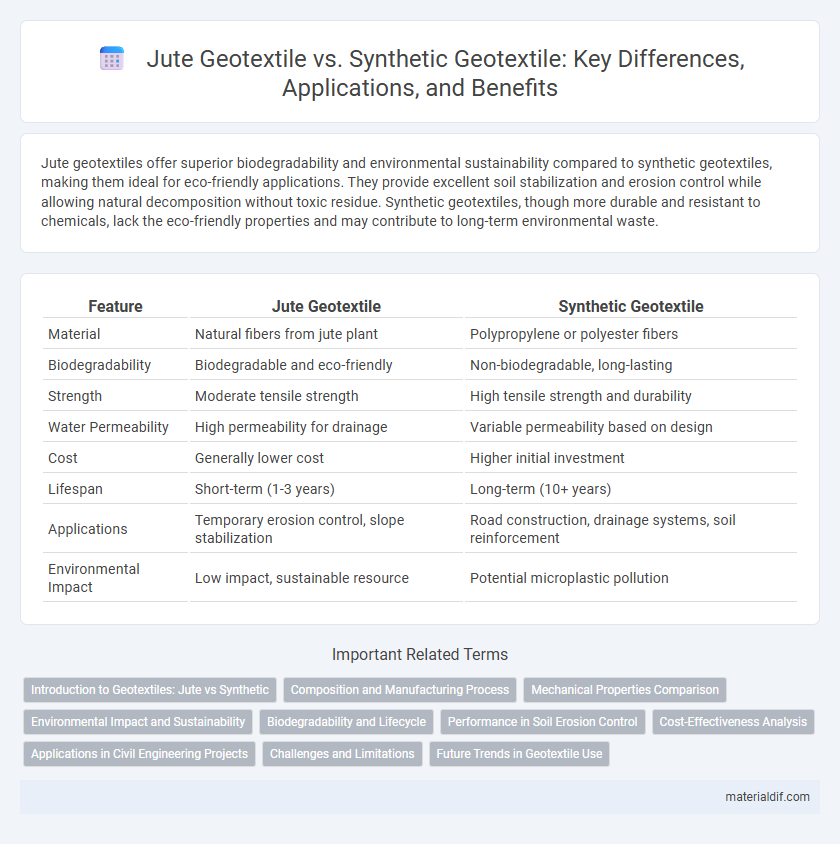

Jute geotextiles offer superior biodegradability and environmental sustainability compared to synthetic geotextiles, making them ideal for eco-friendly applications. They provide excellent soil stabilization and erosion control while allowing natural decomposition without toxic residue. Synthetic geotextiles, though more durable and resistant to chemicals, lack the eco-friendly properties and may contribute to long-term environmental waste.

Table of Comparison

| Feature | Jute Geotextile | Synthetic Geotextile |

|---|---|---|

| Material | Natural fibers from jute plant | Polypropylene or polyester fibers |

| Biodegradability | Biodegradable and eco-friendly | Non-biodegradable, long-lasting |

| Strength | Moderate tensile strength | High tensile strength and durability |

| Water Permeability | High permeability for drainage | Variable permeability based on design |

| Cost | Generally lower cost | Higher initial investment |

| Lifespan | Short-term (1-3 years) | Long-term (10+ years) |

| Applications | Temporary erosion control, slope stabilization | Road construction, drainage systems, soil reinforcement |

| Environmental Impact | Low impact, sustainable resource | Potential microplastic pollution |

Introduction to Geotextiles: Jute vs Synthetic

Jute geotextiles are biodegradable, naturally derived fabrics offering excellent soil stabilization and erosion control, making them ideal for environmentally sensitive projects. Synthetic geotextiles, typically made from polypropylene or polyester, provide higher tensile strength, durability, and resistance to chemicals and UV exposure for long-term infrastructure applications. Selection between jute and synthetic geotextiles depends on project requirements such as environmental impact, durability, and cost-effectiveness.

Composition and Manufacturing Process

Jute geotextiles are made from natural plant fibers derived from the jute plant, featuring biodegradable, eco-friendly properties, while synthetic geotextiles are manufactured from polypropylene or polyester polymers, ensuring higher chemical resistance and durability. The manufacturing process of jute geotextiles involves harvesting, retting, and spinning jute fibers into yarns, followed by weaving or non-woven felting techniques. In contrast, synthetic geotextiles are produced through extrusion, melting, and weaving or knitting polypropylene or polyester fibers into diverse fabric structures tailored for specific engineering applications.

Mechanical Properties Comparison

Jute geotextiles exhibit high tensile strength and moderate elongation, making them suitable for natural erosion control and soil reinforcement in lighter load applications. Synthetic geotextiles, typically made from polypropylene or polyester, offer superior mechanical properties such as significantly higher tensile strength, elongation, and abrasion resistance, enabling them to withstand heavy loads and prolonged exposure to harsh environments. The choice between jute and synthetic geotextiles depends heavily on project requirements for durability, load-bearing capacity, and environmental impact.

Environmental Impact and Sustainability

Jute geotextiles provide a biodegradable and eco-friendly alternative to synthetic geotextiles, significantly reducing soil pollution and microplastic accumulation. The natural fibers in jute decompose within months, enriching the soil without harmful residues, while synthetic options contribute to long-term environmental degradation. Sustainable land and water management prioritize jute geotextiles due to their renewable source and minimal carbon footprint compared to petroleum-based synthetic fabrics.

Biodegradability and Lifecycle

Jute geotextiles offer superior biodegradability, breaking down naturally within 6 to 12 months, which minimizes environmental impact and supports soil health compared to synthetic geotextiles that can persist for decades. The lifecycle of jute geotextiles aligns with temporary erosion control and short-term soil stabilization projects, whereas synthetic geotextiles provide long-term durability but contribute to microplastic pollution. Selecting jute geotextiles enhances sustainability in applications requiring ecological balance without compromising on biodegradability.

Performance in Soil Erosion Control

Jute geotextiles exhibit superior biodegradability and natural moisture retention, promoting vegetation growth that enhances soil stabilization in erosion control applications. Synthetic geotextiles, typically made from polypropylene or polyester, offer higher tensile strength and durability under harsh environmental conditions but may impede natural soil processes due to their non-biodegradable nature. The choice between jute and synthetic geotextiles depends on project duration, environmental impact priorities, and specific soil erosion control requirements.

Cost-Effectiveness Analysis

Jute geotextiles offer a cost-effective alternative to synthetic geotextiles due to their natural biodegradability and lower production expenses, reducing long-term environmental impact and disposal costs. Synthetic geotextiles, while often more durable and resistant to chemicals and UV degradation, typically involve higher initial costs and potential environmental concerns related to microplastic pollution. Evaluating project lifespan, maintenance expenses, and ecological benefits positions jute geotextiles as a sustainable and economically advantageous option in many civil engineering applications.

Applications in Civil Engineering Projects

Jute geotextile offers excellent biodegradable properties and natural water permeability, making it ideal for erosion control and slope stabilization in civil engineering projects. Synthetic geotextiles provide superior tensile strength, durability, and resistance to chemical degradation, which suit long-term applications such as road construction and soil reinforcement. Both materials are widely used, but jute is preferred for environmentally sensitive sites, while synthetic options dominate heavy infrastructure and drainage systems.

Challenges and Limitations

Jute geotextiles face challenges such as lower tensile strength and faster biodegradation compared to synthetic geotextiles, limiting their use in long-term applications. Synthetic geotextiles, while durable and strong, suffer from environmental issues due to non-biodegradability and potential microplastic pollution. Both materials have specific limitations: jute's susceptibility to microbial attack and synthetic textiles' ecological impact require careful selection based on project duration and environmental considerations.

Future Trends in Geotextile Use

Jute geotextiles are gaining traction due to their biodegradability and eco-friendly properties, aligning with the global movement toward sustainable construction materials. Synthetic geotextiles, while offering superior durability and tensile strength, face increased scrutiny over environmental impact and disposal challenges, driving innovation toward bio-based synthetic blends. Future trends indicate a hybrid approach combining natural fibers like jute with advanced synthetic polymers to optimize performance and sustainability in geotechnical applications.

Jute Geotextile vs Synthetic Geotextile Infographic

materialdif.com

materialdif.com