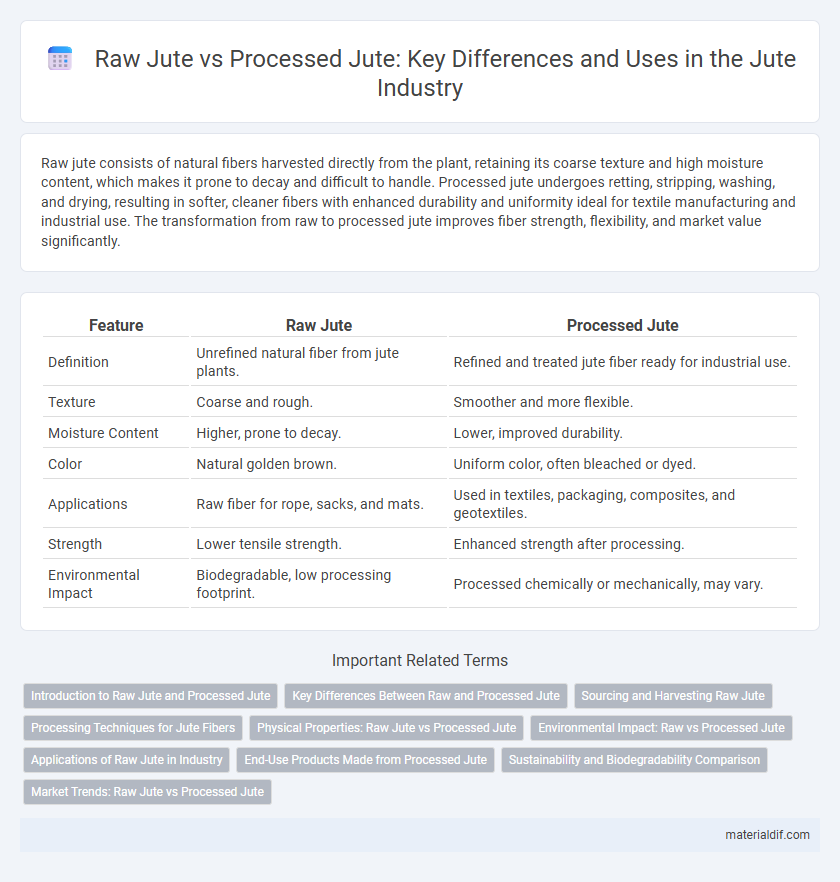

Raw jute consists of natural fibers harvested directly from the plant, retaining its coarse texture and high moisture content, which makes it prone to decay and difficult to handle. Processed jute undergoes retting, stripping, washing, and drying, resulting in softer, cleaner fibers with enhanced durability and uniformity ideal for textile manufacturing and industrial use. The transformation from raw to processed jute improves fiber strength, flexibility, and market value significantly.

Table of Comparison

| Feature | Raw Jute | Processed Jute |

|---|---|---|

| Definition | Unrefined natural fiber from jute plants. | Refined and treated jute fiber ready for industrial use. |

| Texture | Coarse and rough. | Smoother and more flexible. |

| Moisture Content | Higher, prone to decay. | Lower, improved durability. |

| Color | Natural golden brown. | Uniform color, often bleached or dyed. |

| Applications | Raw fiber for rope, sacks, and mats. | Used in textiles, packaging, composites, and geotextiles. |

| Strength | Lower tensile strength. | Enhanced strength after processing. |

| Environmental Impact | Biodegradable, low processing footprint. | Processed chemically or mechanically, may vary. |

Introduction to Raw Jute and Processed Jute

Raw jute is the natural fiber extracted from the stem of jute plants, primarily grown in regions like India and Bangladesh, characterized by its coarse texture and high lignin content. Processed jute undergoes treatments such as retting, washing, and drying to remove impurities, soften the fibers, and enhance durability and usability. The transformation from raw to processed jute significantly improves its application potential in textiles, packaging materials, and eco-friendly products.

Key Differences Between Raw and Processed Jute

Raw jute consists of natural fibers directly harvested from the jute plant, containing impurities like lignin and moisture that affect its texture and quality. Processed jute undergoes retting, cleaning, and bleaching, resulting in finer, softer fibers suitable for textile and packaging industries. The key differences lie in fiber quality, usability, and commercial value, with processed jute offering enhanced durability, uniformity, and aesthetic appeal.

Sourcing and Harvesting Raw Jute

Raw jute is primarily sourced from the stalks of Corchorus plants, cultivated extensively in countries like India, Bangladesh, and China due to their favorable tropical climates. Harvesting involves cutting the plants at the base, followed by retting in water bodies to separate the fibers through microbial action, which is crucial for fiber quality. This raw jute fiber then undergoes processes such as stripping, washing, and drying before it is ready for industrial processing into products like sacks, ropes, and textiles.

Processing Techniques for Jute Fibers

Raw jute fibers undergo retting, stripping, washing, and drying to separate and clean the fibers from the stalks, ensuring optimal quality for further use. Processing techniques such as carding, spinning, and weaving transform raw jute into strong and flexible textiles suitable for bags, rugs, and sacks. Mechanical and chemical treatments enhance fiber durability, softness, and color retention, making processed jute a versatile material in various industrial and eco-friendly applications.

Physical Properties: Raw Jute vs Processed Jute

Raw jute fibers exhibit higher moisture content and greater natural impurities, resulting in coarser texture and lower tensile strength compared to processed jute. Processed jute undergoes cleaning, softening, and sometimes bleaching, which enhances fiber fineness, improves tensile strength, and reduces moisture absorption. The physical properties of processed jute make it more suitable for manufacturing durable textiles and eco-friendly packaging materials.

Environmental Impact: Raw vs Processed Jute

Raw jute is biodegradable and compostable, producing minimal waste and requiring fewer chemical inputs during cultivation, which significantly reduces soil and water pollution. Processed jute undergoes treatments like dyeing and chemical softening that increase water usage and generate effluents containing harmful substances, elevating environmental risks. Comparing both, raw jute presents a lower ecological footprint by maintaining natural fiber properties and conserving resources, while processed jute demands more energy and chemical-intensive processes that contribute to environmental degradation.

Applications of Raw Jute in Industry

Raw jute, characterized by its coarse fibers and natural lignin content, is extensively used in industries such as agriculture for making sacks, bags, and mats that require durability and breathability. Its applications include packaging for commodities like grains, coffee, and tea, as well as erosion control products due to its biodegradability and soil-friendly properties. The natural strength and moisture resistance of raw jute make it ideal for industrial uses where environmental sustainability and cost-efficiency are prioritized.

End-Use Products Made from Processed Jute

Processed jute fibers undergo refinement techniques such as softening, dyeing, and blending to enhance durability and texture, making them ideal for manufacturing eco-friendly bags, home furnishings, and upholstery. End-use products like jute rugs, geo-textiles, and biodegradable packaging leverage the improved strength and flexibility of processed jute, contributing to sustainable industries. This transformation from raw to processed jute amplifies its commercial value and broadens its application across various sectors.

Sustainability and Biodegradability Comparison

Raw jute is a highly sustainable fiber due to its minimal processing requirements and natural biodegradability, decomposing within months without releasing harmful chemicals. Processed jute undergoes various treatments that may involve synthetic chemicals, potentially reducing its biodegradability and increasing environmental impact. Choosing raw jute over processed alternatives supports eco-friendly practices by preserving soil health, minimizing water usage, and ensuring quick natural degradation post-use.

Market Trends: Raw Jute vs Processed Jute

Raw jute dominates traditional markets due to its affordable cost and wide application in packaging and agriculture, but processed jute products, including jute fabric and biocomposites, are rapidly gaining traction driven by increasing demand for sustainable and value-added goods. Market trends indicate a shift towards processed jute exports, especially in Europe and North America, where eco-friendly consumer preferences fuel growth in home textiles and fashion industries. Investment in advanced jute processing technologies is accelerating, enhancing product quality and expanding processed jute market share globally.

Raw jute vs Processed jute Infographic

materialdif.com

materialdif.com