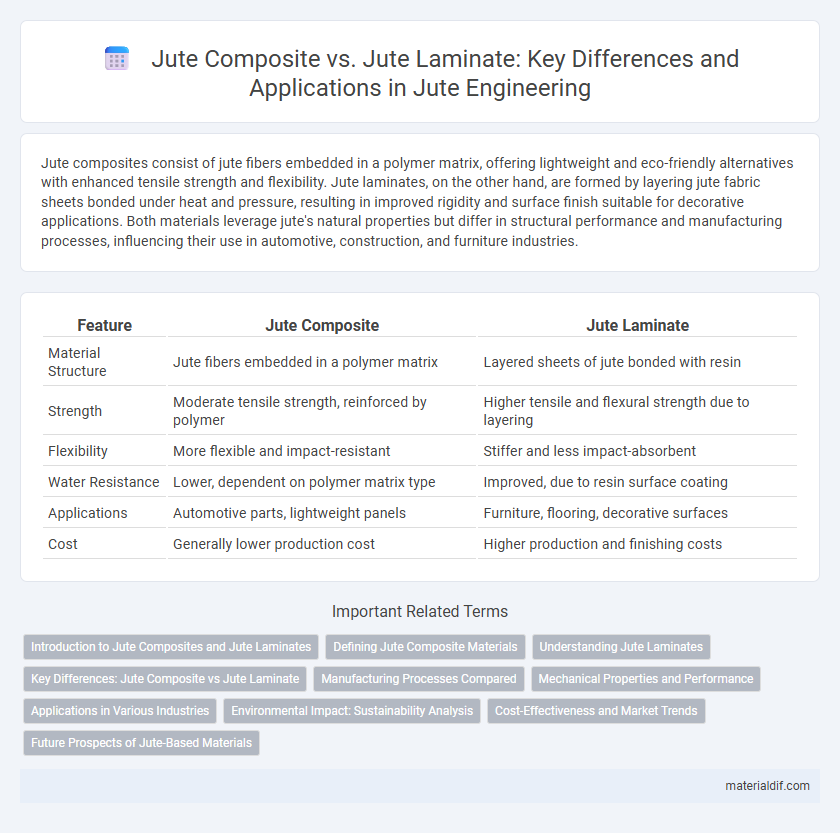

Jute composites consist of jute fibers embedded in a polymer matrix, offering lightweight and eco-friendly alternatives with enhanced tensile strength and flexibility. Jute laminates, on the other hand, are formed by layering jute fabric sheets bonded under heat and pressure, resulting in improved rigidity and surface finish suitable for decorative applications. Both materials leverage jute's natural properties but differ in structural performance and manufacturing processes, influencing their use in automotive, construction, and furniture industries.

Table of Comparison

| Feature | Jute Composite | Jute Laminate |

|---|---|---|

| Material Structure | Jute fibers embedded in a polymer matrix | Layered sheets of jute bonded with resin |

| Strength | Moderate tensile strength, reinforced by polymer | Higher tensile and flexural strength due to layering |

| Flexibility | More flexible and impact-resistant | Stiffer and less impact-absorbent |

| Water Resistance | Lower, dependent on polymer matrix type | Improved, due to resin surface coating |

| Applications | Automotive parts, lightweight panels | Furniture, flooring, decorative surfaces |

| Cost | Generally lower production cost | Higher production and finishing costs |

Introduction to Jute Composites and Jute Laminates

Jute composites consist of natural jute fibers embedded within a polymer matrix, offering enhanced mechanical strength and biodegradability for sustainable applications. Jute laminates are produced by layering multiple jute fiber sheets with resin, creating a rigid, lightweight material suitable for automotive and construction industries. Both materials leverage jute's renewable nature but differ in manufacturing processes and structural properties.

Defining Jute Composite Materials

Jute composite materials consist of natural jute fibers embedded within a polymer matrix, creating a lightweight and eco-friendly alternative to traditional composites. Jute laminates, on the other hand, are formed by stacking multiple layers of jute fabric bonded with resins to enhance mechanical strength and durability. Both materials optimize the use of renewable jute fiber, but jute composites emphasize fiber-matrix integration, while jute laminates focus on layered structural reinforcement.

Understanding Jute Laminates

Jute laminates consist of multiple layers of jute fabric bonded with resin, providing enhanced strength and durability compared to standard jute composites that typically incorporate jute fibers within a single resin matrix. The lamination process improves the mechanical properties, moisture resistance, and impact performance, making jute laminates suitable for automotive, construction, and furniture applications. Understanding jute laminates involves recognizing their superior structural integrity, surface finish, and environmental benefits due to the natural biodegradability of jute fibers combined with advanced manufacturing techniques.

Key Differences: Jute Composite vs Jute Laminate

Jute composite consists of natural jute fibers embedded in a resin matrix, providing lightweight strength and flexibility suitable for automotive and construction applications. Jute laminate is created by layering and bonding jute fabric sheets with resin under heat and pressure, resulting in a rigid, durable material ideal for panels and furniture. Key differences lie in their manufacturing process, structural rigidity, and typical use cases--composites offer more flexibility, while laminates deliver enhanced stiffness and surface finish.

Manufacturing Processes Compared

Jute composites are manufactured by embedding jute fibers into a polymer matrix using processes such as compression molding or resin transfer molding, which ensures uniform fiber distribution and mechanical interlocking. In contrast, jute laminates involve layering woven jute fabrics with adhesives followed by hot pressing, emphasizing controlled thickness and surface finish. The composite process offers enhanced strength due to the resin impregnation, while laminates provide better dimensional stability and surface aesthetics.

Mechanical Properties and Performance

Jute composites exhibit enhanced mechanical properties such as high tensile strength and flexibility, making them suitable for lightweight structural applications. Jute laminates, due to their layered fabrication, often demonstrate superior stiffness, impact resistance, and dimensional stability compared to standard jute composites. Performance variations between these materials influence their selection in industries like automotive and construction, where durability and mechanical efficiency are critical.

Applications in Various Industries

Jute composites are widely used in automotive and construction industries for lightweight panels and insulation due to their high strength-to-weight ratio and eco-friendliness. Jute laminates, offering enhanced durability and moisture resistance, find applications in furniture manufacturing and interior decor where aesthetic appeal and structural integrity are essential. Both materials contribute to sustainable product solutions, reducing reliance on synthetic alternatives across diverse industrial sectors.

Environmental Impact: Sustainability Analysis

Jute composite materials incorporate natural fibers with biodegradable resins, significantly reducing carbon footprints and promoting eco-friendly waste management compared to synthetic composites. Jute laminates, produced by layering jute fibers with thermoset or thermoplastic matrices, offer enhanced durability but may involve higher energy consumption and less recyclability due to the bonding processes used. Life cycle assessments reveal jute composites excel in sustainability by minimizing environmental impact through renewability and lower emissions, whereas jute laminates balance strength with moderate environmental trade-offs.

Cost-Effectiveness and Market Trends

Jute composites offer a cost-effective solution by utilizing natural fibers bonded with resins, reducing raw material expenses compared to synthetic alternatives. Jute laminates, while slightly more expensive due to added processing and layering techniques, provide enhanced durability and structural integrity, appealing to automotive and construction markets targeting sustainability. Market trends show a growing preference for jute composites in eco-friendly packaging, whereas laminates gain traction in high-performance applications demanding strength and aesthetic finesse.

Future Prospects of Jute-Based Materials

Jute composite materials demonstrate significant potential for sustainable construction and automotive industries due to their lightweight, biodegradability, and cost-effectiveness, which align with global environmental goals. Jute laminate offers enhanced mechanical properties and moisture resistance, making it suitable for high-performance applications and expanding its market reach. Continued innovation in jute-based materials is expected to drive growth in eco-friendly product development and foster wider adoption across various industrial sectors.

Jute composite vs Jute laminate Infographic

materialdif.com

materialdif.com