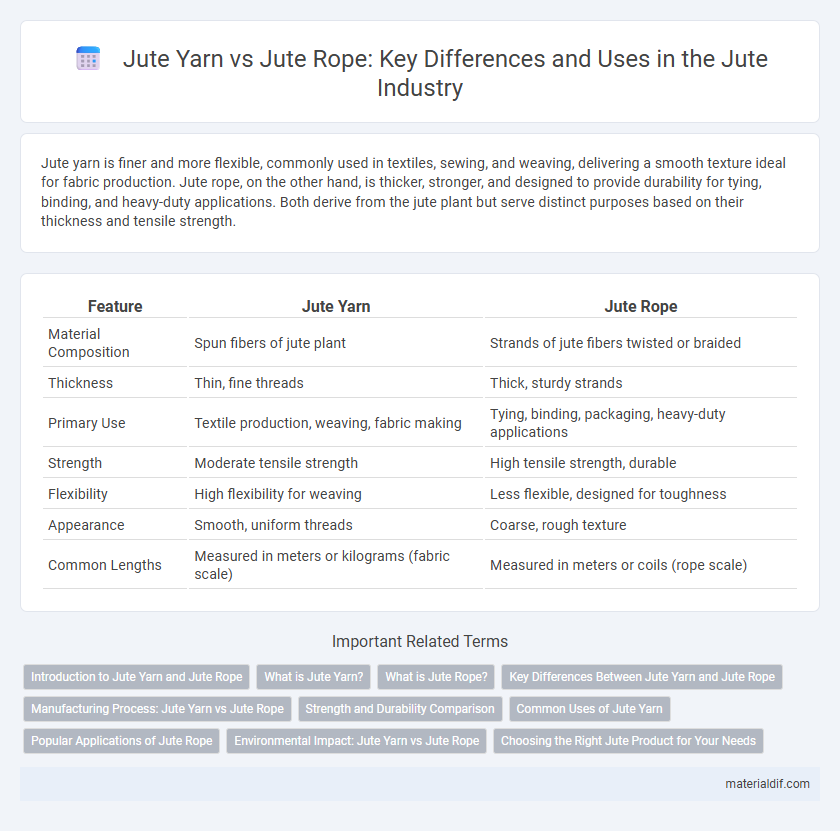

Jute yarn is finer and more flexible, commonly used in textiles, sewing, and weaving, delivering a smooth texture ideal for fabric production. Jute rope, on the other hand, is thicker, stronger, and designed to provide durability for tying, binding, and heavy-duty applications. Both derive from the jute plant but serve distinct purposes based on their thickness and tensile strength.

Table of Comparison

| Feature | Jute Yarn | Jute Rope |

|---|---|---|

| Material Composition | Spun fibers of jute plant | Strands of jute fibers twisted or braided |

| Thickness | Thin, fine threads | Thick, sturdy strands |

| Primary Use | Textile production, weaving, fabric making | Tying, binding, packaging, heavy-duty applications |

| Strength | Moderate tensile strength | High tensile strength, durable |

| Flexibility | High flexibility for weaving | Less flexible, designed for toughness |

| Appearance | Smooth, uniform threads | Coarse, rough texture |

| Common Lengths | Measured in meters or kilograms (fabric scale) | Measured in meters or coils (rope scale) |

Introduction to Jute Yarn and Jute Rope

Jute yarn is a fine, spun fiber derived from the jute plant, commonly used in textiles, bags, and upholstery due to its softness and flexibility. Jute rope, on the other hand, is a thicker, twisted product made from multiple jute fibers, designed for strength and durability in applications like tying, packaging, and agriculture. Both products capitalize on jute's natural biodegradability, sustainability, and resistance to moisture, making them popular eco-friendly materials.

What is Jute Yarn?

Jute yarn is a natural fiber thread spun from the jute plant, commonly used for weaving and knitting various textile products. It features a finer texture compared to jute rope, making it ideal for creating fabrics, sacks, and carpets. High tensile strength and eco-friendly properties differentiate jute yarn as a sustainable material in the textile industry.

What is Jute Rope?

Jute rope is a strong, natural fiber rope made from the twisted strands of jute yarn, widely used for its durability and eco-friendliness in packaging, agriculture, and marine applications. Unlike jute yarn, which is finer and primarily used for textile production, jute rope features thicker, tightly twisted fibers designed to withstand heavy loads and resist wear. Its biodegradability and tensile strength make jute rope an ideal sustainable alternative to synthetic ropes in various industries.

Key Differences Between Jute Yarn and Jute Rope

Jute yarn consists of fine, spun fibers primarily used for weaving textiles, while jute rope is made by twisting multiple jute yarns together to form a strong, durable cord. The key differences lie in their applications--jute yarn is preferred in fabric and sacking industries due to its softness, whereas jute rope is favored for agricultural, marine, and packaging uses for its tensile strength. Additionally, jute rope typically has a coarser texture and greater thickness compared to the finer, more flexible nature of jute yarn.

Manufacturing Process: Jute Yarn vs Jute Rope

Jute yarn is produced by spinning natural jute fibers into fine threads, involving processes like fiber softening, carding, and spinning to achieve a smooth texture suitable for textiles. Jute rope, on the other hand, is manufactured by twisting multiple jute fibers or strands together using specialized rope-making machines, resulting in a thicker, stronger product designed for heavy-duty applications. The key difference lies in the yarn's fine, uniform quality for fabric production, while rope manufacturing emphasizes tensile strength and durability through fiber bundling and twisting techniques.

Strength and Durability Comparison

Jute rope exhibits higher tensile strength and superior durability compared to jute yarn, making it ideal for heavy-duty applications like binding and lifting. Jute yarn, while strong, is finer and better suited for textile production where flexibility and softness are priorities. The natural fibers in both retain good abrasion resistance, but rope construction enhances jute's overall robustness under stress.

Common Uses of Jute Yarn

Jute yarn is primarily used in the textile industry for making hessian cloth, sacks, carpets, and upholstery due to its softness and flexibility compared to jute rope. It is favored for producing eco-friendly bags, mats, and woven fabrics, serving as a sustainable alternative in packaging and home decor. Unlike jute rope, which is stronger and coarser for heavy-duty binding and tying, jute yarn enables finer craftsmanship in textile products.

Popular Applications of Jute Rope

Jute rope is widely used in agriculture for tying crops and securing plants due to its strength and biodegradability. It is also popular in packaging industries for bundling and wrapping heavy items safely. Additionally, jute rope is favored in crafts and home decor for its rustic appearance and natural texture.

Environmental Impact: Jute Yarn vs Jute Rope

Jute yarn and jute rope both derive from the natural jute fiber, renowned for its biodegradability and low environmental footprint compared to synthetic alternatives. Jute yarn, typically used in finer textile applications, requires less energy-intensive processing, resulting in lower carbon emissions and reduced water consumption relative to the thicker, more robust jute rope manufacturing. The environmental impact of jute rope is higher mainly due to extra resources consumed in twisting and treating processes that enhance durability, but both products contribute minimally to plastic pollution and promote sustainable agriculture practices.

Choosing the Right Jute Product for Your Needs

Jute yarn offers flexibility and smooth texture ideal for textile applications such as weaving and knitting, while jute rope provides superior strength and durability suited for heavy-duty tasks like bundling and construction. Selecting the right jute product depends on the specific use case, with yarn best for fine crafts and rope optimized for load-bearing requirements. Understanding the tensile strength, thickness, and finish of each can ensure optimal performance and longevity in your project.

Jute Yarn vs Jute Rope Infographic

materialdif.com

materialdif.com