Jute yarn offers a coarse texture and high durability, making it ideal for eco-friendly pet products that require strength and biodegradability. Linen yarn, derived from flax fibers, provides a smoother, softer feel with excellent moisture-wicking properties, enhancing comfort for pets. Choosing between jute and linen yarn depends on balancing toughness with softness to suit specific pet product needs.

Table of Comparison

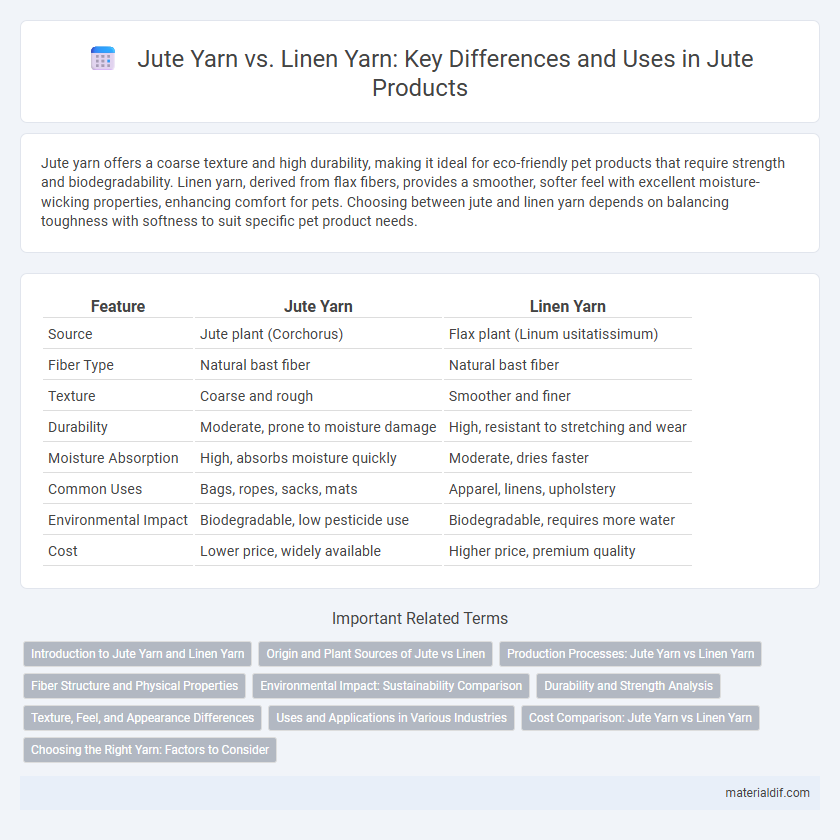

| Feature | Jute Yarn | Linen Yarn |

|---|---|---|

| Source | Jute plant (Corchorus) | Flax plant (Linum usitatissimum) |

| Fiber Type | Natural bast fiber | Natural bast fiber |

| Texture | Coarse and rough | Smoother and finer |

| Durability | Moderate, prone to moisture damage | High, resistant to stretching and wear |

| Moisture Absorption | High, absorbs moisture quickly | Moderate, dries faster |

| Common Uses | Bags, ropes, sacks, mats | Apparel, linens, upholstery |

| Environmental Impact | Biodegradable, low pesticide use | Biodegradable, requires more water |

| Cost | Lower price, widely available | Higher price, premium quality |

Introduction to Jute Yarn and Linen Yarn

Jute yarn is a natural fiber known for its coarse texture, high tensile strength, and affordability, commonly used in making sacks, ropes, and mats. Linen yarn, derived from flax fibers, offers a smoother texture, superior durability, and a luxurious feel ideal for high-quality fabrics and upholstery. Both fibers are biodegradable and sustainable, but jute excels in industrial applications while linen is preferred in fashion and home textiles.

Origin and Plant Sources of Jute vs Linen

Jute yarn originates from the Corchorus plant, primarily cultivated in South Asia, especially Bangladesh and India, where the fiber is harvested from the outer bast of the plant's stem. Linen yarn, on the other hand, is derived from the flax plant, native to the Mediterranean and Western Europe, with fibers extracted from the flax stalk's inner bark. The distinct botanical sources influence the texture, strength, and traditional uses of jute and linen yarn in textile production.

Production Processes: Jute Yarn vs Linen Yarn

Jute yarn is produced through a retting process where jute fibers are soaked in water to separate them from the stalk, followed by mechanical extraction and spinning. Linen yarn originates from flax fibers, extracted using dew retting or water retting, with additional steps like scutching and hackling to refine the fibers before spinning. The production of jute yarn involves quicker retting times and coarser fibers, while linen yarn production requires more intricate processing for finer, smoother fiber quality.

Fiber Structure and Physical Properties

Jute yarn features long, coarse fibers with a high lignin content, resulting in a rough texture and lower tensile strength compared to linen yarn. Linen yarn derives from flax fibers that are smoother, finer, and possess higher cellulose content, providing superior durability and elasticity. The physical properties of jute yarn make it ideal for heavy-duty applications like sacks and ropes, while linen yarn's softness suits apparel and fine textiles.

Environmental Impact: Sustainability Comparison

Jute yarn has a significantly lower environmental impact compared to linen yarn due to its rapid growth cycle and minimal need for pesticides or fertilizers, making it a highly sustainable crop. Unlike linen, which requires intensive water and chemical use during flax cultivation and fiber processing, jute cultivation promotes soil health and reduces carbon footprint. The biodegradability and compostability of jute yarn further enhance its sustainability profile in eco-friendly textile production.

Durability and Strength Analysis

Jute yarn exhibits moderate durability and tensile strength, making it suitable for products like sacks and rugs where flexibility and biodegradability are essential. Linen yarn, derived from flax fibers, offers superior strength and durability with a smoother texture, ideal for high-quality textiles and apparel requiring long-lasting wear. Comparative analysis reveals linen yarn's higher cellulose content and fiber alignment contribute to its enhanced tensile strength, whereas jute's coarser fibers provide less resilience but greater affordability.

Texture, Feel, and Appearance Differences

Jute yarn features a coarse texture with a rough, fibrous feel and a naturally golden-brown hue, lending a rustic and earthy appearance. Linen yarn, derived from flax fibers, provides a smoother, softer touch with a subtle sheen and lighter, creamy-white color that offers a refined and elegant look. The durability of jute contrasts with linen's breathable quality, making each yarn suited for different textile applications based on texture and aesthetic preferences.

Uses and Applications in Various Industries

Jute yarn is widely used in the packaging industry for making sacks, ropes, and mats due to its strength and biodegradability, while linen yarn, derived from flax fibers, is preferred in the textile and fashion industries for producing high-quality garments, upholstery, and home textiles because of its smooth texture and durability. Jute yarn's cost-effectiveness and eco-friendly properties make it ideal for agricultural and construction applications such as erosion control mats and geotextiles, whereas linen yarn is valued in luxury interior design for curtains, tablecloths, and fine fabrics. Both fibers find unique applications that leverage their distinct physical characteristics, with jute dominating heavy-duty industrial uses and linen excelling in premium clothing and artisanal crafts.

Cost Comparison: Jute Yarn vs Linen Yarn

Jute yarn is significantly more cost-effective than linen yarn due to the lower cultivation and processing expenses associated with jute fibers, making it an economical choice for bulk textile production. Linen yarn's production involves labor-intensive harvesting and specialized processing, resulting in higher market prices. The affordability of jute yarn supports its widespread use in packaging, upholstery, and eco-friendly textiles compared to the premium positioning of linen yarn in high-end apparel and home decor.

Choosing the Right Yarn: Factors to Consider

Choosing the right yarn for your project depends on durability, texture, and environmental impact, where jute yarn offers coarseness and high tensile strength ideal for rustic crafts and eco-friendly products. Linen yarn, derived from flax fibers, provides a smoother, finer texture with excellent moisture-wicking properties, making it suitable for lightweight fabrics and apparel. Consider the end-use, fiber characteristics, and sustainability goals to optimize your material choice between jute and linen yarn.

Jute Yarn vs Linen Yarn Infographic

materialdif.com

materialdif.com