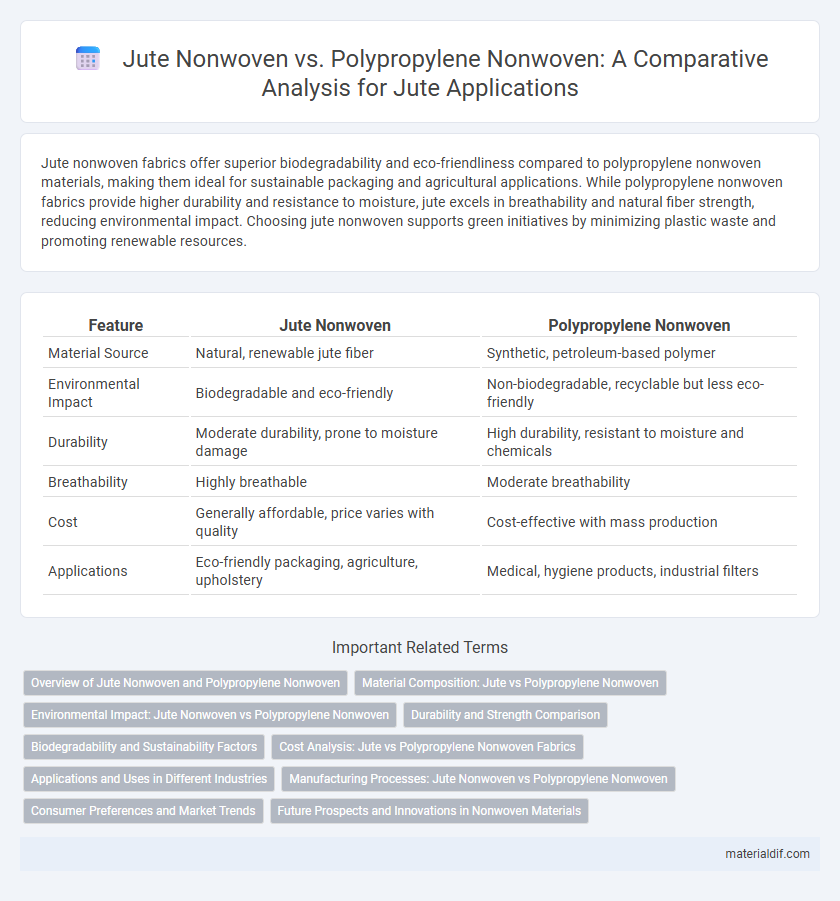

Jute nonwoven fabrics offer superior biodegradability and eco-friendliness compared to polypropylene nonwoven materials, making them ideal for sustainable packaging and agricultural applications. While polypropylene nonwoven fabrics provide higher durability and resistance to moisture, jute excels in breathability and natural fiber strength, reducing environmental impact. Choosing jute nonwoven supports green initiatives by minimizing plastic waste and promoting renewable resources.

Table of Comparison

| Feature | Jute Nonwoven | Polypropylene Nonwoven |

|---|---|---|

| Material Source | Natural, renewable jute fiber | Synthetic, petroleum-based polymer |

| Environmental Impact | Biodegradable and eco-friendly | Non-biodegradable, recyclable but less eco-friendly |

| Durability | Moderate durability, prone to moisture damage | High durability, resistant to moisture and chemicals |

| Breathability | Highly breathable | Moderate breathability |

| Cost | Generally affordable, price varies with quality | Cost-effective with mass production |

| Applications | Eco-friendly packaging, agriculture, upholstery | Medical, hygiene products, industrial filters |

Overview of Jute Nonwoven and Polypropylene Nonwoven

Jute nonwoven fabric is a natural fiber product known for its biodegradability, breathability, and eco-friendly properties, making it ideal for sustainable packaging and agricultural applications. Polypropylene nonwoven fabric, derived from synthetic polymers, offers high durability, moisture resistance, and cost-effectiveness, widely used in medical, hygiene, and filtration products. Both materials provide versatile solutions, with jute emphasizing environmental benefits and polypropylene excelling in performance and affordability.

Material Composition: Jute vs Polypropylene Nonwoven

Jute nonwoven fabric is crafted from natural vegetable fibers derived from the jute plant, offering biodegradable and eco-friendly properties. Polypropylene nonwoven consists of synthetic polymers made from petroleum-based materials, known for durability and moisture resistance but lacking biodegradability. The natural cellulose and lignin content in jute provides breathability and biodegradability, whereas the hydrophobic nature of polypropylene results in water repellency and longer lifespan.

Environmental Impact: Jute Nonwoven vs Polypropylene Nonwoven

Jute nonwoven fabric demonstrates significantly lower environmental impact compared to polypropylene nonwoven due to its biodegradable and renewable nature, reducing plastic pollution and landfill burden. Production of jute nonwoven consumes less energy and emits fewer greenhouse gases, supporting sustainable agriculture and carbon sequestration. In contrast, polypropylene nonwoven relies on petrochemical resources, contributing to microplastic contamination and persistent ecological harm.

Durability and Strength Comparison

Jute nonwoven fabrics exhibit higher tensile strength and enhanced durability compared to polypropylene nonwoven materials due to their natural fiber composition and robust lignin content. Polypropylene nonwoven fabrics, while lightweight and resistant to moisture, tend to have lower tear resistance and degrade faster under UV exposure. The eco-friendly nature of jute fibers also contributes to their superior mechanical performance and long-term stability in industrial and agricultural applications.

Biodegradability and Sustainability Factors

Jute nonwoven fabrics exhibit superior biodegradability compared to polypropylene nonwoven, decomposing naturally within months without releasing toxic residues. As a renewable plant-based fiber, jute contributes significantly to sustainability by reducing reliance on fossil fuels and lowering carbon footprints during production. Polypropylene, a synthetic polymer, poses environmental challenges due to its persistence in ecosystems and reliance on non-renewable resources.

Cost Analysis: Jute vs Polypropylene Nonwoven Fabrics

Jute nonwoven fabrics typically have a lower raw material cost compared to polypropylene nonwoven, making them a cost-effective option for sustainable textile applications. Production expenses for jute involve natural fiber processing, which can be less energy-intensive but may require more labor than the synthetic manufacturing of polypropylene. Despite polypropylene's advantages in durability and water resistance, the overall cost advantage often shifts toward jute nonwoven fabrics due to rising petroleum prices impacting polypropylene.

Applications and Uses in Different Industries

Jute nonwoven fabrics are widely utilized in eco-friendly packaging, agriculture, and geotextiles due to their natural biodegradability and moisture retention properties. Polypropylene nonwoven materials dominate medical, hygiene, and filtration industries because of their durability, chemical resistance, and cost-effectiveness. The choice between jute and polypropylene nonwoven depends on specific industry requirements, emphasizing sustainability in agriculture and packaging versus performance in medical and industrial applications.

Manufacturing Processes: Jute Nonwoven vs Polypropylene Nonwoven

Jute nonwoven fabric is produced through mechanical bonding methods like needle punching or hydroentangling, utilizing natural jute fibers that require retting and decortication prior to web formation. Polypropylene nonwoven fabric manufacturing involves meltblown or spunbond processes, where polymer granules are melted and extruded into continuous filaments that are thermally bonded to form the fabric. The production of jute nonwoven emphasizes eco-friendly, low-energy processing, whereas polypropylene nonwoven manufacturing relies on energy-intensive polymer extrusion and thermal bonding techniques.

Consumer Preferences and Market Trends

Jute nonwoven fabrics are gaining consumer preference due to their biodegradable nature and eco-friendly appeal, contrasting with polypropylene nonwoven's reliance on synthetic polymers. Market trends indicate a rising demand for sustainable materials, positioning jute nonwoven as a preferred choice in eco-conscious packaging and fashion sectors. Consumer awareness about environmental impact drives the shift towards natural fibers, boosting jute's market share in nonwoven applications.

Future Prospects and Innovations in Nonwoven Materials

Jute nonwoven materials exhibit promising future prospects due to their biodegradability, renewability, and superior moisture absorption compared to polypropylene nonwovens, which rely on fossil fuels and pose environmental concerns. Innovations in jute fiber treatment and hybrid composites enhance mechanical strength and durability, positioning jute nonwovens as sustainable alternatives in packaging, agriculture, and geotextiles. Advancements in bio-based adhesives and eco-friendly finishing techniques further accelerate the adoption of jute nonwoven fabrics in green technology sectors.

Jute Nonwoven vs Polypropylene Nonwoven Infographic

materialdif.com

materialdif.com