Jute twine is thinner and more flexible, making it ideal for lightweight packaging, gardening, and craft projects, while jute rope is thicker and stronger, suited for heavier-duty applications such as construction, boating, and securing loads. Both products are biodegradable and eco-friendly, but their choice depends on the required strength and flexibility for specific tasks. Jute rope provides higher tensile strength, whereas jute twine offers ease of handling and knotting for delicate uses.

Table of Comparison

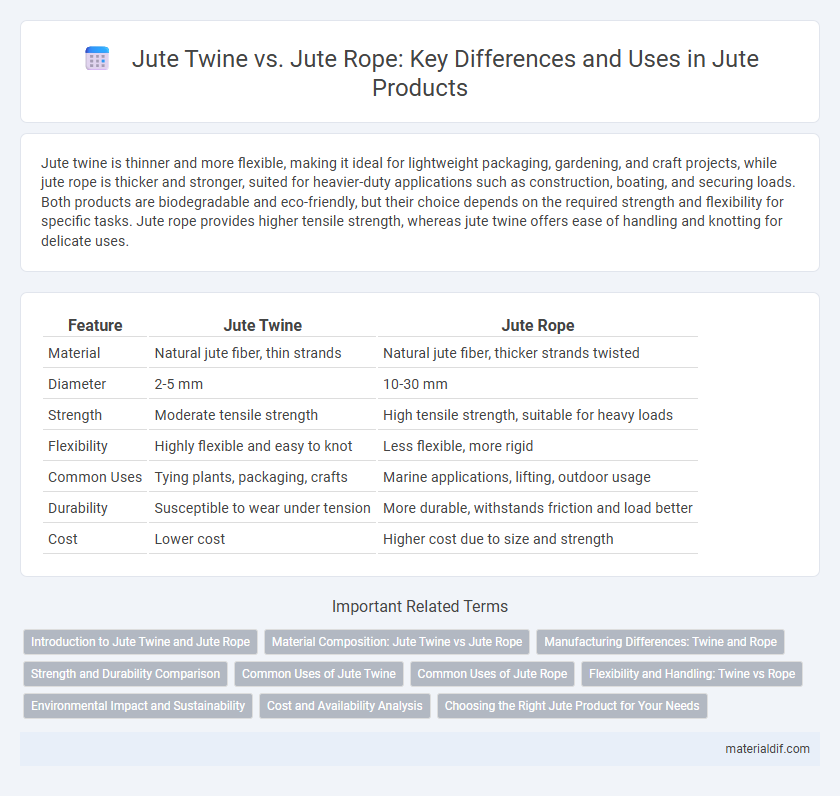

| Feature | Jute Twine | Jute Rope |

|---|---|---|

| Material | Natural jute fiber, thin strands | Natural jute fiber, thicker strands twisted |

| Diameter | 2-5 mm | 10-30 mm |

| Strength | Moderate tensile strength | High tensile strength, suitable for heavy loads |

| Flexibility | Highly flexible and easy to knot | Less flexible, more rigid |

| Common Uses | Tying plants, packaging, crafts | Marine applications, lifting, outdoor usage |

| Durability | Susceptible to wear under tension | More durable, withstands friction and load better |

| Cost | Lower cost | Higher cost due to size and strength |

Introduction to Jute Twine and Jute Rope

Jute twine consists of thin, tightly twisted fibers ideal for lightweight bundling and crafts, offering flexibility and ease of handling. Jute rope, made from thicker, braided or twisted jute strands, provides enhanced strength and durability suited for heavy-duty applications like agriculture and construction. Both varieties leverage jute's natural biodegradability and resistance to moisture, making them eco-friendly alternatives to synthetic fibers.

Material Composition: Jute Twine vs Jute Rope

Jute twine is composed of tightly twisted fibers that create a thinner, more flexible strand ideal for light bundling and crafting, while jute rope features multiple plies of twisted jute fibers, resulting in a thicker, stronger cord designed for heavy-duty applications. Both materials are made from natural jute fiber, known for its durability, biodegradability, and resistance to moisture, but the difference in fiber density and ply structure significantly impacts their tensile strength and usage. The material composition of jute twine emphasizes pliability and ease of knotting, whereas jute rope prioritizes structural integrity and load-bearing capacity.

Manufacturing Differences: Twine and Rope

Jute twine is manufactured by tightly twisting thinner jute fibers into fine strands, resulting in a lightweight and flexible product primarily used for binding and packaging. In contrast, jute rope production involves braiding or twisting multiple thicker strands of jute twine together, creating a stronger and more durable cord ideal for heavy-duty applications like shipping and construction. The differing manufacturing processes affect the tensile strength, thickness, and usage versatility of jute twine versus jute rope.

Strength and Durability Comparison

Jute twine offers moderate tensile strength suitable for light bundling and crafting tasks, while jute rope provides significantly higher strength and durability, making it ideal for heavy-duty applications such as agriculture and construction. The thicker, tightly woven fibers in jute rope enhance resistance to abrasion and weathering compared to the finer, more flexible jute twine. When long-term durability and load-bearing capacity are critical, jute rope outperforms twine due to its robust construction and fiber density.

Common Uses of Jute Twine

Jute twine is commonly used for bundling plants, securing packages, and crafting due to its flexibility and strength. It is preferred in gardening and agricultural settings for tying seedlings and supporting climbing plants without damaging stems. Jute twine's lightweight nature and biodegradability make it ideal for eco-friendly gift wrapping and artisanal projects.

Common Uses of Jute Rope

Jute rope is commonly used in agriculture for tying plants, securing bales of hay, and supporting climbing crops due to its strength and durability. It also finds applications in crafting, shipping, and construction for bundling materials and creating natural fiber nets. Unlike jute twine, which is thinner and suited for lightweight tasks, jute rope handles heavier loads and outdoor exposure effectively.

Flexibility and Handling: Twine vs Rope

Jute twine offers superior flexibility and ease of handling compared to jute rope, making it ideal for delicate bundling, gardening, and crafting tasks. Jute rope, thicker and sturdier, provides greater tensile strength but is less pliable, suited for heavy-duty applications like construction and agriculture. The finer, softer texture of twine enhances knotting and tying efficiency while rope's rigidity supports load-bearing and durability requirements.

Environmental Impact and Sustainability

Jute twine and jute rope both offer environmentally friendly alternatives to synthetic fibers due to their biodegradable and renewable nature. Jute twine, being thinner and lighter, requires less raw material and energy to produce, resulting in a lower carbon footprint compared to thicker jute rope. Both products contribute to sustainable agriculture by supporting natural fiber markets and reducing plastic waste in packaging and agriculture.

Cost and Availability Analysis

Jute twine typically offers a lower cost compared to jute rope due to its thinner gauge and simpler manufacturing process, making it more budget-friendly for light-duty tasks. Availability of jute twine is generally higher in retail markets because it serves diverse applications such as gardening and packaging, whereas jute rope, being thicker and stronger, is primarily stocked in industrial or agricultural supply outlets. Cost efficiency combined with widespread availability makes jute twine preferable for everyday, low-strength needs, while jute rope is chosen for durability despite a higher price point and more limited distribution.

Choosing the Right Jute Product for Your Needs

Selecting between jute twine and jute rope depends on the strength requirements and application type; jute twine offers flexibility and finer strength for light binding, gardening, and crafting tasks. Jute rope provides greater thickness and tensile strength, ideal for heavy-duty uses such as tying, lifting, or outdoor installations. Assess the weight load, durability needs, and environmental exposure to ensure the optimal jute product for your project.

Jute twine vs Jute rope Infographic

materialdif.com

materialdif.com