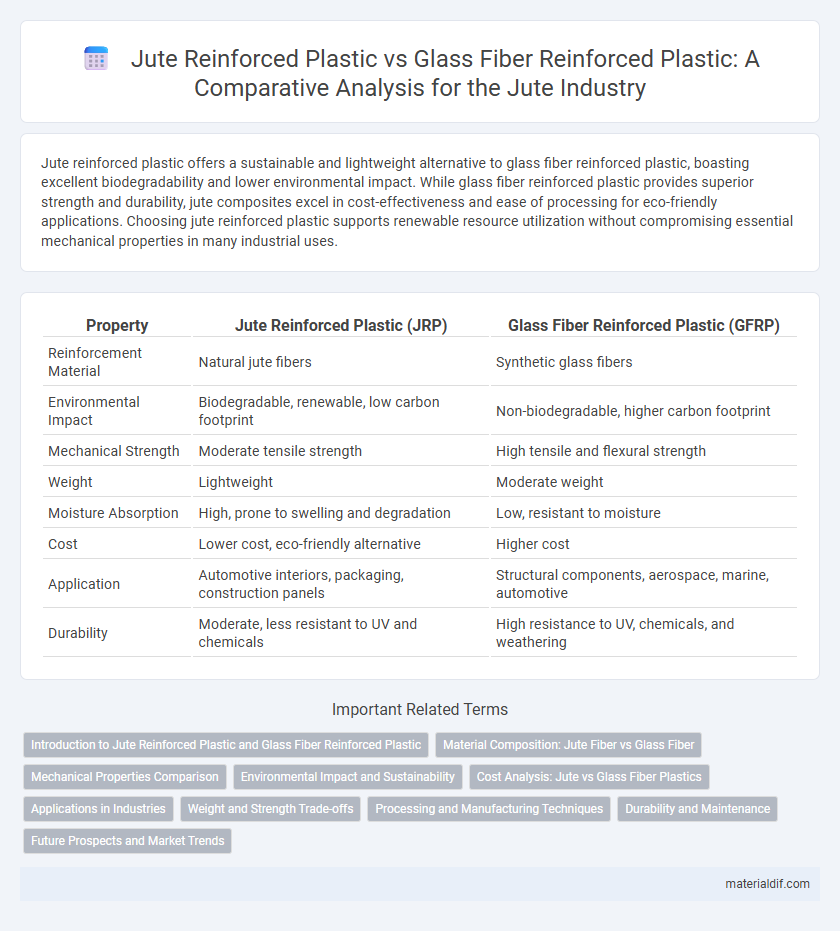

Jute reinforced plastic offers a sustainable and lightweight alternative to glass fiber reinforced plastic, boasting excellent biodegradability and lower environmental impact. While glass fiber reinforced plastic provides superior strength and durability, jute composites excel in cost-effectiveness and ease of processing for eco-friendly applications. Choosing jute reinforced plastic supports renewable resource utilization without compromising essential mechanical properties in many industrial uses.

Table of Comparison

| Property | Jute Reinforced Plastic (JRP) | Glass Fiber Reinforced Plastic (GFRP) |

|---|---|---|

| Reinforcement Material | Natural jute fibers | Synthetic glass fibers |

| Environmental Impact | Biodegradable, renewable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Mechanical Strength | Moderate tensile strength | High tensile and flexural strength |

| Weight | Lightweight | Moderate weight |

| Moisture Absorption | High, prone to swelling and degradation | Low, resistant to moisture |

| Cost | Lower cost, eco-friendly alternative | Higher cost |

| Application | Automotive interiors, packaging, construction panels | Structural components, aerospace, marine, automotive |

| Durability | Moderate, less resistant to UV and chemicals | High resistance to UV, chemicals, and weathering |

Introduction to Jute Reinforced Plastic and Glass Fiber Reinforced Plastic

Jute Reinforced Plastic (JRP) combines natural jute fibers with a plastic matrix, offering a biodegradable and cost-effective alternative for composite materials. Glass Fiber Reinforced Plastic (GFRP) incorporates glass fibers within a polymer matrix, known for its high strength, durability, and resistance to corrosion. JRP provides environmental benefits and lightweight properties, while GFRP excels in mechanical performance and long-term stability in construction and automotive applications.

Material Composition: Jute Fiber vs Glass Fiber

Jute Reinforced Plastic (JRP) utilizes natural jute fibers derived from the Corchorus plant, offering biodegradable, lightweight, and renewable material properties, while Glass Fiber Reinforced Plastic (GFRP) incorporates synthetic glass fibers known for superior tensile strength, durability, and resistance to corrosion. The cellulose-based jute fibers provide good mechanical reinforcement and environmental sustainability, whereas glass fibers consist mainly of silica, delivering higher structural performance but with less eco-friendliness. Material composition differences impact the composites' applications, with JRP favored in eco-sensitive sectors and GFRP preferred for demanding structural requirements.

Mechanical Properties Comparison

Jute Reinforced Plastic (JRP) offers a lower density and improved biodegradability compared to Glass Fiber Reinforced Plastic (GFRP), but typically exhibits reduced tensile strength and modulus. GFRP outperforms JRP in impact resistance and fatigue endurance due to its synthetic fiber reinforcement. Mechanical property trade-offs position JRP as a sustainable alternative with moderate strength, whereas GFRP remains preferred for high-performance structural applications.

Environmental Impact and Sustainability

Jute Reinforced Plastic (JRP) offers significant environmental benefits over Glass Fiber Reinforced Plastic (GFRP) due to its biodegradability and lower carbon footprint, as jute cultivation absorbs more CO2 compared to the energy-intensive production of glass fibers. The renewable nature of jute fibers reduces dependence on non-renewable resources and generates less pollution during manufacturing and disposal. Sustainable agriculture practices linked with jute farming further enhance soil health and decrease environmental degradation compared to synthetic fiber production.

Cost Analysis: Jute vs Glass Fiber Plastics

Jute Reinforced Plastic (JRP) offers significant cost advantages over Glass Fiber Reinforced Plastic (GFRP) due to lower raw material and production expenses, as jute fibers are renewable and abundant in regions like South Asia. While GFRP typically incurs higher costs from energy-intensive manufacturing and non-renewable resin components, JRP's biodegradability and ease of processing further reduce lifecycle costs. Cost analysis reveals that JRP is a financially viable alternative in applications prioritizing sustainability and budget efficiency without compromising mechanical performance.

Applications in Industries

Jute Reinforced Plastic (JRP) is increasingly utilized in automotive and construction industries due to its biodegradability, lightweight nature, and cost-effectiveness compared to Glass Fiber Reinforced Plastic (GFRP). Glass Fiber Reinforced Plastic maintains superiority in aerospace and marine applications because of its high tensile strength, corrosion resistance, and durability in extreme environments. Both materials cater to sustainable development goals, with JRP offering eco-friendly alternatives in packaging and interior panels, while GFRP supports high-performance demands in structural and industrial equipment manufacturing.

Weight and Strength Trade-offs

Jute Reinforced Plastic (JRP) offers significantly lower weight compared to Glass Fiber Reinforced Plastic (GFRP), enhancing fuel efficiency and ease of handling in automotive and construction applications. Despite its lighter weight, JRP exhibits competitive tensile strength, though GFRP typically provides superior overall strength and durability in high-stress environments. The weight-to-strength ratio of JRP makes it an eco-friendly alternative where moderate strength and reduced weight are critical factors.

Processing and Manufacturing Techniques

Jute Reinforced Plastic (JRP) utilizes natural fibers extracted from jute plants, requiring careful treatment to enhance fiber-matrix bonding and moisture resistance during processing. Glass Fiber Reinforced Plastic (GFRP) involves the integration of synthetic glass fibers, employing techniques like hand lay-up, spray-up, and filament winding for consistent strength and dimensional stability. Manufacturing JRP demands eco-friendly resin systems to accommodate the hydrophilic nature of jute, whereas GFRP processing benefits from the inherent durability and chemical resistance of glass fibers, allowing for higher temperature curing cycles.

Durability and Maintenance

Jute Reinforced Plastic (JRP) offers natural fiber composition that enhances biodegradability but generally exhibits lower durability compared to Glass Fiber Reinforced Plastic (GFRP), which boasts superior tensile strength and resistance to environmental degradation. Maintenance of JRP requires more frequent inspections and protective coatings to prevent moisture absorption and fiber decay, whereas GFRP demands minimal upkeep due to its corrosion resistance and stable mechanical properties under various conditions. The choice between JRP and GFRP hinges on balancing sustainability preferences against long-term durability and low-maintenance advantages.

Future Prospects and Market Trends

Jute Reinforced Plastic (JRP) is gaining traction in sustainable materials markets due to its biodegradability and lower carbon footprint, appealing to eco-conscious industries. Glass Fiber Reinforced Plastic (GFRP) remains dominant in high-strength applications but faces increasing scrutiny over environmental impact and recycling challenges. Emerging trends indicate a growing investment in JRP research and development, driven by regulatory shifts favoring green composites and rising consumer demand for sustainable alternatives.

Jute Reinforced Plastic vs Glass Fiber Reinforced Plastic Infographic

materialdif.com

materialdif.com