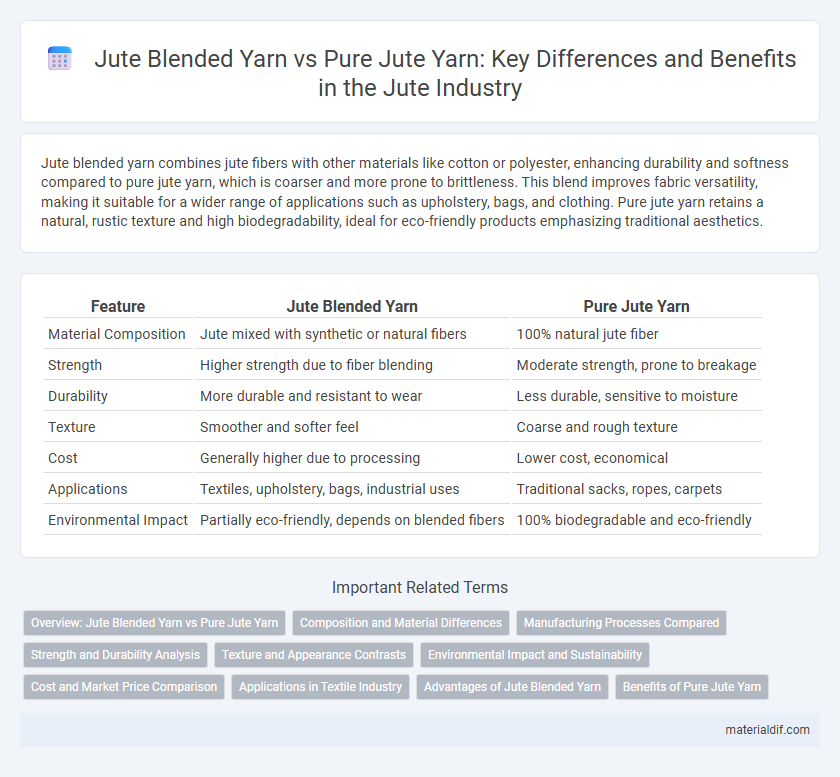

Jute blended yarn combines jute fibers with other materials like cotton or polyester, enhancing durability and softness compared to pure jute yarn, which is coarser and more prone to brittleness. This blend improves fabric versatility, making it suitable for a wider range of applications such as upholstery, bags, and clothing. Pure jute yarn retains a natural, rustic texture and high biodegradability, ideal for eco-friendly products emphasizing traditional aesthetics.

Table of Comparison

| Feature | Jute Blended Yarn | Pure Jute Yarn |

|---|---|---|

| Material Composition | Jute mixed with synthetic or natural fibers | 100% natural jute fiber |

| Strength | Higher strength due to fiber blending | Moderate strength, prone to breakage |

| Durability | More durable and resistant to wear | Less durable, sensitive to moisture |

| Texture | Smoother and softer feel | Coarse and rough texture |

| Cost | Generally higher due to processing | Lower cost, economical |

| Applications | Textiles, upholstery, bags, industrial uses | Traditional sacks, ropes, carpets |

| Environmental Impact | Partially eco-friendly, depends on blended fibers | 100% biodegradable and eco-friendly |

Overview: Jute Blended Yarn vs Pure Jute Yarn

Jute blended yarn combines natural jute fibers with synthetic or other natural fibers, enhancing strength, durability, and versatility compared to pure jute yarn. Pure jute yarn, derived solely from the jute plant, offers excellent biodegradability and a coarse texture ideal for eco-friendly packaging and traditional textile products. The choice between jute blended yarn and pure jute yarn depends on specific application requirements such as tensile strength, softness, and environmental impact.

Composition and Material Differences

Jute blended yarn combines jute fibers with synthetic or cotton fibers, enhancing strength, elasticity, and durability compared to pure jute yarn, which consists entirely of natural jute fibers known for their coarse texture and biodegradability. The blend improves moisture resistance and reduces brittleness, making it suitable for a wider range of industrial and textile applications. Pure jute yarn maintains eco-friendly properties but lacks the flexibility and tensile strength offered by blended compositions.

Manufacturing Processes Compared

Jute blended yarn manufacturing involves combining jute fibers with other fibers such as cotton or polyester, using processes like carding, spinning, and blending to enhance yarn strength and flexibility. Pure jute yarn production relies solely on traditional methods including fiber retting, combing, and spinning, preserving the natural coarse texture and biodegradable properties of jute. Blended yarn processes incorporate additional machinery to uniformly mix fibers, resulting in yarn suitable for diverse textile applications compared to the more limited uses of pure jute yarn.

Strength and Durability Analysis

Jute blended yarn combines natural jute fibers with synthetic materials, enhancing overall strength and durability compared to pure jute yarn, which tends to be weaker and more prone to wear and tear under stress. The integration of synthetic fibers in blended yarn improves tensile strength, abrasion resistance, and longevity, making it suitable for heavy-duty applications such as upholstery and industrial textiles. Pure jute yarn, while eco-friendly and biodegradable, lacks the reinforced toughness found in blended yarns, limiting its use to lighter or decorative products.

Texture and Appearance Contrasts

Jute blended yarn combines natural jute fibers with synthetic or cotton fibers, resulting in a smoother texture and enhanced strength compared to pure jute yarn. Pure jute yarn maintains its coarse and rustic texture, offering a natural, earthy appearance ideal for traditional crafts and packaging. Blended jute yarn exhibits improved softness and uniformity in color, catering to textile applications where both durability and aesthetic appeal are essential.

Environmental Impact and Sustainability

Jute blended yarn combines natural fibers with synthetic or other plant-based materials, reducing reliance on pure jute and enhancing durability while maintaining biodegradability. Pure jute yarn offers superior environmental benefits due to its fully natural composition, requiring fewer chemical treatments and promoting soil health through crop rotation. Both options support sustainable practices, but pure jute yarn stands out for its minimal carbon footprint and easier recyclability compared to blends.

Cost and Market Price Comparison

Jute blended yarn typically costs more than pure jute yarn due to the inclusion of synthetic or cotton fibers that enhance durability and texture. Market prices for pure jute yarn remain lower, attracting industries focused on eco-friendly and biodegradable materials. The cost difference influences consumer preference, with blended yarns favored in sectors demanding strength and pure jute yarns preferred for traditional packaging and textile uses.

Applications in Textile Industry

Jute blended yarn combines natural jute fibers with synthetic or cotton fibers, enhancing durability and flexibility, making it ideal for upholstery, home furnishings, and eco-friendly fashion textiles. Pure jute yarn retains its coarse texture and strength, commonly used in sacks, ropes, and industrial fabrics where biodegradability and cost-effectiveness are prioritized. Textile manufacturers favor blended yarn for versatile applications requiring softness and resilience while pure jute yarn suits traditional and heavy-duty textile products.

Advantages of Jute Blended Yarn

Jute blended yarn combines natural fibers with synthetic or other textile fibers, enhancing strength, elasticity, and durability compared to pure jute yarn. This blend improves resistance to wear and tear, minimizes shrinkage, and offers better moisture absorption, making it ideal for diverse applications such as upholstery, carpets, and industrial fabrics. The increased versatility and cost-effectiveness of jute blended yarn provide superior performance in both traditional and modern textile manufacturing.

Benefits of Pure Jute Yarn

Pure jute yarn offers superior biodegradability and sustainability compared to jute blended yarn, making it an eco-friendly choice for textile manufacturing. It provides better strength and durability while maintaining the natural texture and appearance of jute fibers. Furthermore, pure jute yarn enhances breathability and moisture absorption, ideal for producing high-quality sacks, rugs, and handicrafts.

Jute Blended Yarn vs Pure Jute Yarn Infographic

materialdif.com

materialdif.com