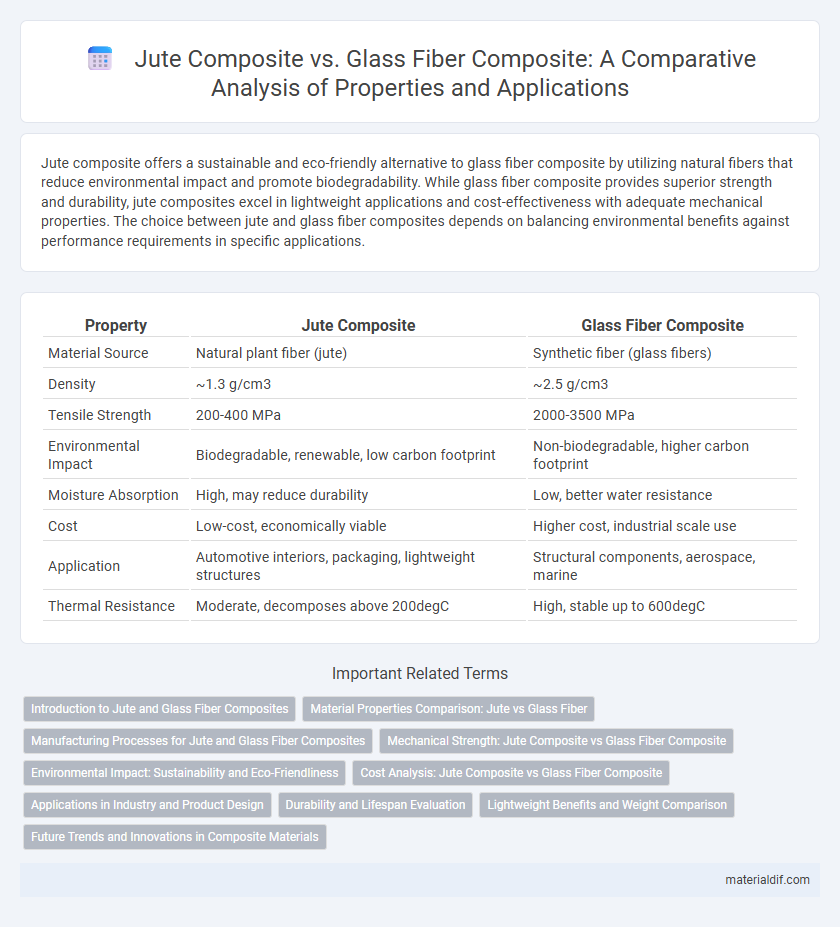

Jute composite offers a sustainable and eco-friendly alternative to glass fiber composite by utilizing natural fibers that reduce environmental impact and promote biodegradability. While glass fiber composite provides superior strength and durability, jute composites excel in lightweight applications and cost-effectiveness with adequate mechanical properties. The choice between jute and glass fiber composites depends on balancing environmental benefits against performance requirements in specific applications.

Table of Comparison

| Property | Jute Composite | Glass Fiber Composite |

|---|---|---|

| Material Source | Natural plant fiber (jute) | Synthetic fiber (glass fibers) |

| Density | ~1.3 g/cm3 | ~2.5 g/cm3 |

| Tensile Strength | 200-400 MPa | 2000-3500 MPa |

| Environmental Impact | Biodegradable, renewable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Moisture Absorption | High, may reduce durability | Low, better water resistance |

| Cost | Low-cost, economically viable | Higher cost, industrial scale use |

| Application | Automotive interiors, packaging, lightweight structures | Structural components, aerospace, marine |

| Thermal Resistance | Moderate, decomposes above 200degC | High, stable up to 600degC |

Introduction to Jute and Glass Fiber Composites

Jute composites are produced by reinforcing natural jute fibers within a polymer matrix, offering a sustainable and biodegradable alternative to traditional materials. Glass fiber composites, composed of fine glass fibers embedded in a resin, provide superior strength, durability, and resistance to corrosion, making them commonly used in automotive and construction industries. The choice between jute and glass fiber composites depends on balancing ecological benefits and mechanical performance requirements.

Material Properties Comparison: Jute vs Glass Fiber

Jute composites offer lower density and enhanced biodegradability compared to glass fiber composites, making them ideal for sustainable applications. Although glass fiber composites provide superior tensile strength and impact resistance, jute composites demonstrate favorable vibration damping and cost-effectiveness. Moisture absorption is higher in jute composites, necessitating proper treatment to improve durability and mechanical performance.

Manufacturing Processes for Jute and Glass Fiber Composites

Jute composites are manufactured using eco-friendly processes like hand lay-up, compression molding, and resin transfer molding, where natural jute fibers are embedded in biopolymers or thermoset resins. In contrast, glass fiber composites involve more energy-intensive techniques such as filament winding, pultrusion, and spray-up methods, utilizing synthetic glass fibers combined with polyester or epoxy resins. The lower processing temperature and renewable nature of jute fibers enable cost-effective and sustainable composite production compared to the chemically intensive and energy-demanding manufacturing of glass fiber composites.

Mechanical Strength: Jute Composite vs Glass Fiber Composite

Jute composites exhibit lower mechanical strength compared to glass fiber composites, with tensile strength typically ranging between 30-50 MPa, whereas glass fiber composites achieve tensile strengths of 200-350 MPa. The elastic modulus of jute composites usually falls between 3-7 GPa, significantly less than the 70-85 GPa observed in glass fiber composites. Despite inferior mechanical properties, jute composites offer advantages in biodegradability and lower density, making them suitable for applications where sustainability is prioritized over maximum strength.

Environmental Impact: Sustainability and Eco-Friendliness

Jute composites exhibit significantly lower environmental impact compared to glass fiber composites due to their biodegradable nature and renewable sourcing from jute plants, which require minimal pesticides and fertilizers. The production of jute composites generates less energy consumption and carbon emissions, enhancing their sustainability profile. Conversely, glass fiber composites rely on energy-intensive manufacturing and non-renewable raw materials, resulting in higher ecological footprints and challenges in recycling.

Cost Analysis: Jute Composite vs Glass Fiber Composite

Jute composites offer significantly lower production costs compared to glass fiber composites due to the natural, renewable sources and less energy-intensive manufacturing processes involved. While glass fiber composites provide superior mechanical properties, their raw materials and processing expenses contribute to higher overall costs. Cost analysis reveals jute composites as a cost-effective alternative for applications prioritizing affordability and sustainability.

Applications in Industry and Product Design

Jute composites offer sustainable alternatives to glass fiber composites, excelling in automotive interiors, packaging, and building materials due to their biodegradability and lightweight nature. Glass fiber composites dominate structural applications like aerospace and sports equipment, prized for their superior strength and durability. Product design leverages jute composites for eco-friendly, low-cost solutions, while glass fiber composites are chosen for high-performance, long-lasting products.

Durability and Lifespan Evaluation

Jute composites offer notable biodegradability and eco-friendliness but typically exhibit lower durability and shorter lifespan compared to glass fiber composites, which provide superior resistance to moisture, UV exposure, and mechanical stress. Glass fiber composites maintain structural integrity for 20 to 30 years in harsh environments, whereas jute composites may degrade in less than 10 years due to natural fiber susceptibility. Advances in resin formulations and fiber treatments for jute composites can improve durability but still generally lag behind the extended longevity of glass fiber alternatives.

Lightweight Benefits and Weight Comparison

Jute composites offer significant lightweight benefits compared to glass fiber composites, with jute fibers typically having a density around 1.3-1.5 g/cm3, whereas glass fibers weigh approximately 2.5 g/cm3. The reduced density of jute composites translates into lower overall component weight, enhancing fuel efficiency and ease of handling in automotive and construction applications. Lightweight jute composites also contribute to decreased environmental impact, aligning with sustainable material goals without compromising mechanical strength.

Future Trends and Innovations in Composite Materials

Jute composites are gaining traction due to their biodegradability, low cost, and lightweight properties, making them a sustainable alternative to glass fiber composites. Future trends emphasize enhancing jute fiber treatment and resin compatibility to improve mechanical strength and durability, narrowing the performance gap with glass fiber composites. Innovations in hybrid composites combining jute and glass fibers are emerging, optimizing cost-efficiency, environmental impact, and structural integrity for automotive and construction applications.

Jute Composite vs Glass Fiber Composite Infographic

materialdif.com

materialdif.com