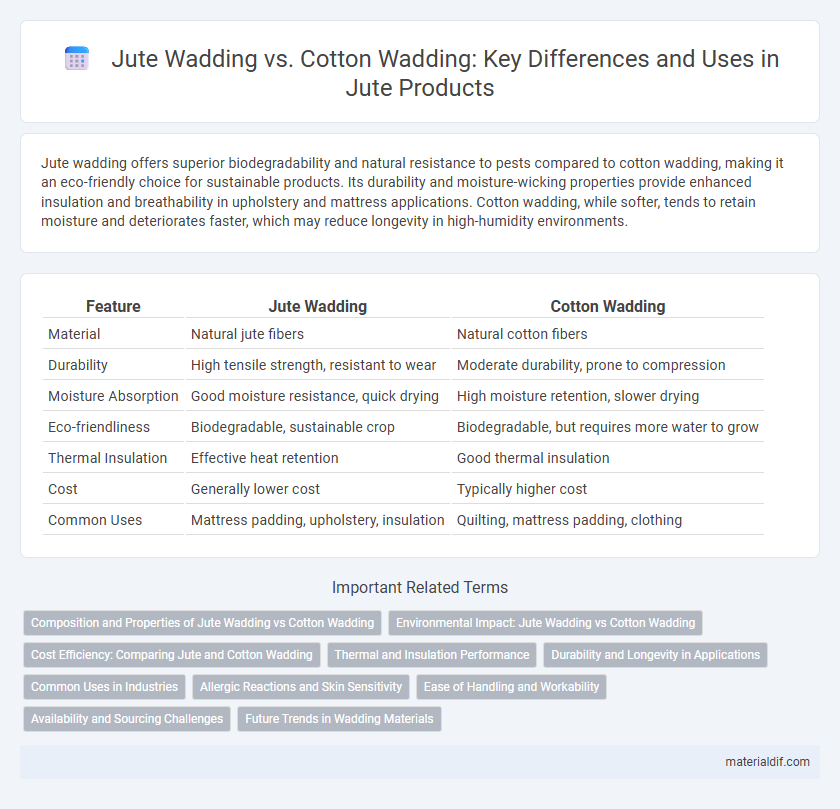

Jute wadding offers superior biodegradability and natural resistance to pests compared to cotton wadding, making it an eco-friendly choice for sustainable products. Its durability and moisture-wicking properties provide enhanced insulation and breathability in upholstery and mattress applications. Cotton wadding, while softer, tends to retain moisture and deteriorates faster, which may reduce longevity in high-humidity environments.

Table of Comparison

| Feature | Jute Wadding | Cotton Wadding |

|---|---|---|

| Material | Natural jute fibers | Natural cotton fibers |

| Durability | High tensile strength, resistant to wear | Moderate durability, prone to compression |

| Moisture Absorption | Good moisture resistance, quick drying | High moisture retention, slower drying |

| Eco-friendliness | Biodegradable, sustainable crop | Biodegradable, but requires more water to grow |

| Thermal Insulation | Effective heat retention | Good thermal insulation |

| Cost | Generally lower cost | Typically higher cost |

| Common Uses | Mattress padding, upholstery, insulation | Quilting, mattress padding, clothing |

Composition and Properties of Jute Wadding vs Cotton Wadding

Jute wadding consists primarily of natural jute fibers, known for their coarse texture, high tensile strength, and excellent moisture absorption, making it durable and breathable. Cotton wadding is made from soft cotton fibers, offering superior softness, hypoallergenic properties, and greater cushioning due to its fine fiber structure. The composition of jute wadding results in a more rigid and eco-friendly material, while cotton wadding provides enhanced comfort and flexibility in textile and upholstery applications.

Environmental Impact: Jute Wadding vs Cotton Wadding

Jute wadding has a significantly lower environmental impact compared to cotton wadding due to its rapid growth cycle, requiring minimal pesticides and water. Cotton cultivation demands extensive water use and heavy chemical inputs, contributing to soil degradation and pollution. Jute's biodegradable and renewable nature makes it a more sustainable choice for eco-friendly textile production.

Cost Efficiency: Comparing Jute and Cotton Wadding

Jute wadding offers superior cost efficiency compared to cotton wadding due to its lower raw material and production costs. Jute is a fast-growing, renewable fiber that requires less water and pesticides, reducing overall expenses in agriculture and processing. Cotton wadding, while softer, often incurs higher prices driven by intensive farming practices and longer processing times.

Thermal and Insulation Performance

Jute wadding exhibits superior thermal insulation due to its coarse fiber structure and natural air-trapping properties, making it ideal for heat retention in upholstery and bedding. Cotton wadding, while softer and more breathable, has less effective insulation capabilities as it allows more heat transfer and moisture retention. The natural resilience of jute fibers enhances durability and maintains warmth longer compared to the denser, softer cotton fibers.

Durability and Longevity in Applications

Jute wadding exhibits superior durability compared to cotton wadding due to its naturally coarse and strong fibers, making it ideal for long-lasting upholstery and insulation applications. The biodegradability of jute allows it to withstand environmental stress without significant degradation over time, whereas cotton wadding tends to compress and deteriorate faster under similar conditions. Consequently, jute wadding offers enhanced longevity in heavy-use scenarios, reducing the need for frequent replacement and maintenance.

Common Uses in Industries

Jute wadding is widely used in the automotive industry for insulation and upholstery due to its natural durability and eco-friendliness, while cotton wadding is preferred in the textile and bedding industries for its softness and breathability. In furniture manufacturing, jute wadding provides cost-effective padding and soundproofing, whereas cotton wadding offers superior cushioning in mattresses and quilts. Both materials find application in filtration and packaging, but jute's biodegradability makes it more suitable for sustainable product solutions.

Allergic Reactions and Skin Sensitivity

Jute wadding is naturally hypoallergenic and breathable, reducing the likelihood of allergic reactions and irritation for individuals with sensitive skin. Cotton wadding, while soft and common in textiles, can sometimes retain allergens like dust mites or chemical residues, potentially triggering sensitivities. Choosing jute wadding supports better skin health by minimizing exposure to common allergens and maintaining moisture balance.

Ease of Handling and Workability

Jute wadding offers superior ease of handling due to its natural coarseness and lightweight structure, making it less slippery and easier to position during upholstery work compared to cotton wadding. The fibrous texture of jute allows for better grip and stability, reducing shifting and bunching, which enhances overall workability in crafting and padding applications. Cotton wadding, while softer, tends to compress more and can be more challenging to manipulate precisely without additional support.

Availability and Sourcing Challenges

Jute wadding is more readily available in regions like South Asia, particularly India and Bangladesh, where jute cultivation is prominent, whereas cotton wadding depends heavily on cotton-producing countries such as the United States, China, and India. Sourcing jute wadding often faces fewer supply chain disruptions due to its strong local production base and lower reliance on global trade, while cotton wadding availability can be impacted by seasonal crop yields, climate variability, and international trade policies. Consequently, jute wadding offers a more sustainable and stable supply option compared to the fluctuating availability of cotton wadding caused by agricultural and market uncertainties.

Future Trends in Wadding Materials

Jute wadding is gaining traction as an eco-friendly alternative to cotton wadding due to its biodegradability and sustainable cultivation. Innovations in jute processing enhance its softness and durability, positioning it as a key material in future textile and upholstery markets. Growing demand for sustainable and cost-effective wadding materials drives investment in jute-based composites and blends.

Jute Wadding vs Cotton Wadding Infographic

materialdif.com

materialdif.com