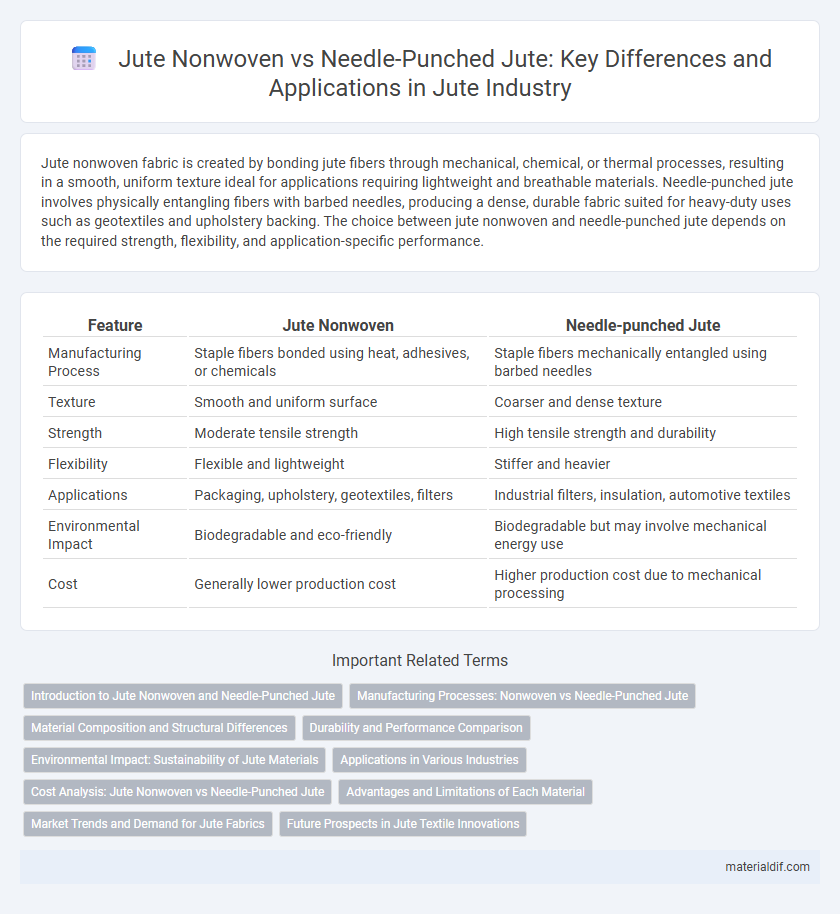

Jute nonwoven fabric is created by bonding jute fibers through mechanical, chemical, or thermal processes, resulting in a smooth, uniform texture ideal for applications requiring lightweight and breathable materials. Needle-punched jute involves physically entangling fibers with barbed needles, producing a dense, durable fabric suited for heavy-duty uses such as geotextiles and upholstery backing. The choice between jute nonwoven and needle-punched jute depends on the required strength, flexibility, and application-specific performance.

Table of Comparison

| Feature | Jute Nonwoven | Needle-punched Jute |

|---|---|---|

| Manufacturing Process | Staple fibers bonded using heat, adhesives, or chemicals | Staple fibers mechanically entangled using barbed needles |

| Texture | Smooth and uniform surface | Coarser and dense texture |

| Strength | Moderate tensile strength | High tensile strength and durability |

| Flexibility | Flexible and lightweight | Stiffer and heavier |

| Applications | Packaging, upholstery, geotextiles, filters | Industrial filters, insulation, automotive textiles |

| Environmental Impact | Biodegradable and eco-friendly | Biodegradable but may involve mechanical energy use |

| Cost | Generally lower production cost | Higher production cost due to mechanical processing |

Introduction to Jute Nonwoven and Needle-Punched Jute

Jute nonwoven fabric is created by bonding jute fibers using adhesive or thermal methods, resulting in a fabric with enhanced uniformity and strength suitable for eco-friendly applications. Needle-punched jute involves mechanically entangling fibers through barbed needles, producing a dense, durable material commonly used for geotextiles and upholstery. Both methods optimize jute's natural properties, but needle-punched jute offers superior mechanical strength while nonwoven jute provides more flexibility and softness.

Manufacturing Processes: Nonwoven vs Needle-Punched Jute

Jute nonwoven fabric is created by bonding jute fibers together using adhesives, heat, or pressure without weaving or knitting, resulting in a lightweight, uniform material ideal for applications like geotextiles and packaging. Needle-punched jute fabric involves mechanically entangling fibers with barbed needles, producing a denser, thicker fabric with enhanced durability and strength suited for heavy-duty uses such as upholstery and carpet backing. The key manufacturing difference lies in nonwoven jute relying on bonding techniques, whereas needle-punched jute depends on physical entanglement for fiber cohesion.

Material Composition and Structural Differences

Jute nonwoven fabric consists of loose jute fibers bonded together through mechanical, chemical, or thermal processes, creating a lightweight and flexible material ideal for packaging and upholstery. Needle-punched jute involves interlocking jute fibers using barbed needles, producing a denser, more durable fabric with enhanced tensile strength suitable for geotextiles and carpet backing. The key structural difference lies in fiber entanglement methods, where nonwoven jute relies on bonding agents while needle-punched jute depends on physical fiber interlocking.

Durability and Performance Comparison

Jute nonwoven fabrics exhibit moderate durability suitable for lightweight applications, whereas needle-punched jute demonstrates superior strength and resilience due to the interlocking of fibers through mechanical needling. Needle-punched jute offers enhanced abrasion resistance and dimensional stability, making it ideal for heavy-duty uses such as geotextiles and upholstery. Overall, needle-punched jute outperforms jute nonwoven in terms of durability and long-term performance under stress.

Environmental Impact: Sustainability of Jute Materials

Jute nonwoven fabric offers superior sustainability compared to needle-punched jute due to its reduced energy consumption and minimal chemical use during production. The biodegradability and natural fiber content of both materials contribute to environmental benefits, but nonwoven jute's manufacturing process results in lower carbon emissions and reduced water usage. Choosing jute nonwoven supports eco-friendly practices by maximizing resource efficiency and minimizing ecological footprint.

Applications in Various Industries

Jute nonwoven fabric is widely used in agriculture for soil erosion control and packaging due to its lightweight and breathable properties, while needle-punched jute offers enhanced strength and durability, making it ideal for automotive upholstery and geotextiles. Industries such as construction utilize needle-punched jute for insulation and erosion control mats, whereas the fashion and home decor sectors prefer jute nonwoven for eco-friendly bags and liners. Both forms of jute provide sustainable alternatives in sectors like agriculture, automotive, construction, and home furnishings, with their application determined by required durability and texture.

Cost Analysis: Jute Nonwoven vs Needle-Punched Jute

Jute nonwoven fabric generally offers a lower production cost compared to needle-punched jute due to its simpler manufacturing process that requires less energy and machinery. Needle-punched jute involves more labor-intensive steps and higher equipment maintenance, increasing overall expenses. Cost efficiency of jute nonwoven makes it a preferred option for applications requiring bulk production with budget constraints.

Advantages and Limitations of Each Material

Jute nonwoven fabric offers advantages such as lightweight construction, cost-effectiveness, and better breathability, making it suitable for applications like packaging and agriculture. However, it has lower tensile strength and durability compared to needle-punched jute, limiting its use in heavy-duty contexts. Needle-punched jute provides superior mechanical strength, enhanced durability, and higher resistance to wear and tear, but it tends to be heavier and more expensive, which can restrict its use in lightweight or budget-sensitive products.

Market Trends and Demand for Jute Fabrics

The market for jute nonwoven fabrics is experiencing steady growth due to rising demand in eco-friendly packaging and geotextile applications, driven by increasing environmental regulations globally. Needle-punched jute fabrics are gaining traction in automotive and upholstery sectors for their enhanced durability and cost-effectiveness. Both segments reflect a broader shift towards sustainable materials, with expanding utilization in construction, agriculture, and fashion industries fueling overall jute fabric demand.

Future Prospects in Jute Textile Innovations

Jute nonwoven fabrics offer lightweight, eco-friendly alternatives with potential for enhanced biodegradability and cost-effective production, making them ideal for sustainable packaging and agricultural applications. Needle-punched jute textiles provide superior strength and durability, which supports their expanding use in geotextiles and automotive composites. Innovations in blending jute fibers with synthetic or bio-based materials promise to improve performance characteristics, driving future growth in technical textiles and environmentally conscious markets.

Jute Nonwoven vs Needle-punched Jute Infographic

materialdif.com

materialdif.com