Jute bagging offers superior breathability and biodegradability compared to polyethylene bagging, making it an eco-friendly choice for sustainable packaging. While polyethylene bags provide durability and water resistance, they contribute to environmental pollution due to their non-biodegradable nature. Choosing jute over polyethylene reduces plastic waste and promotes a renewable, natural fiber alternative in bagging solutions.

Table of Comparison

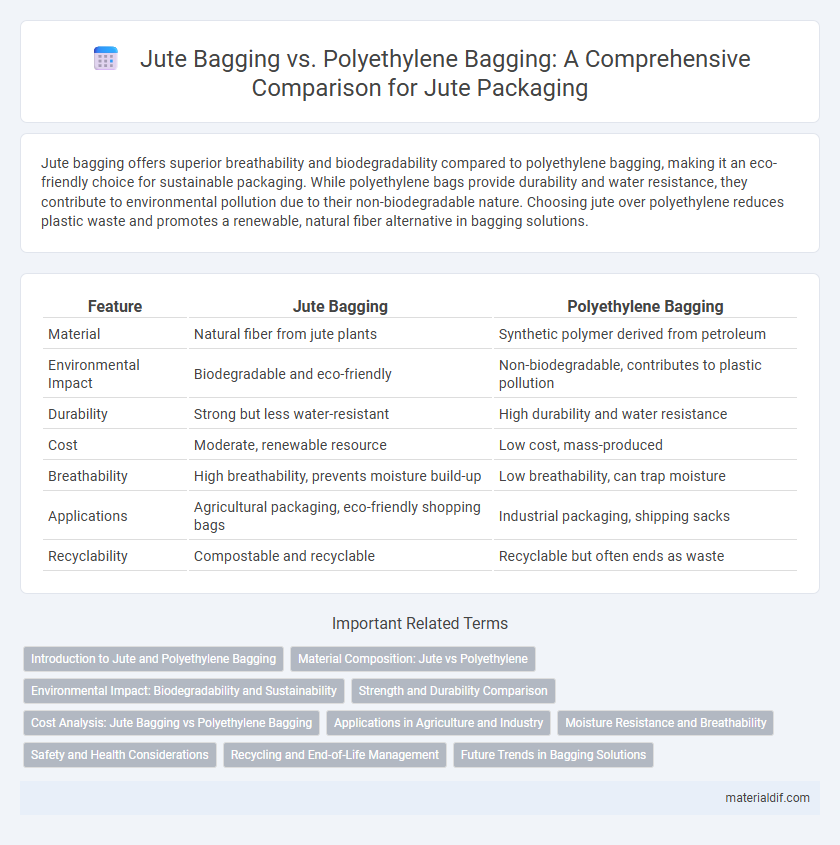

| Feature | Jute Bagging | Polyethylene Bagging |

|---|---|---|

| Material | Natural fiber from jute plants | Synthetic polymer derived from petroleum |

| Environmental Impact | Biodegradable and eco-friendly | Non-biodegradable, contributes to plastic pollution |

| Durability | Strong but less water-resistant | High durability and water resistance |

| Cost | Moderate, renewable resource | Low cost, mass-produced |

| Breathability | High breathability, prevents moisture build-up | Low breathability, can trap moisture |

| Applications | Agricultural packaging, eco-friendly shopping bags | Industrial packaging, shipping sacks |

| Recyclability | Compostable and recyclable | Recyclable but often ends as waste |

Introduction to Jute and Polyethylene Bagging

Jute bagging, made from natural, biodegradable fibers, offers eco-friendly packaging with high breathability and durability, ideal for agricultural products and bulk storage. Polyethylene bagging, constructed from synthetic polymers, provides moisture resistance and strength, making it suitable for waterproof and long-term storage applications. Choosing between jute and polyethylene depends on environmental considerations, product type, and storage conditions.

Material Composition: Jute vs Polyethylene

Jute bagging is crafted from natural vegetable fibers derived from the jute plant, offering biodegradability and eco-friendliness. Polyethylene bagging, composed of synthetic polymers derived from petroleum, provides increased durability and water resistance but lacks environmental sustainability. The material composition difference significantly impacts their environmental footprint, with jute being renewable and polyethylene contributing to plastic pollution.

Environmental Impact: Biodegradability and Sustainability

Jute bagging offers significant environmental benefits due to its natural biodegradability, breaking down within months without releasing harmful microplastics, unlike polyethylene bags which persist for centuries in landfills. The sustainable cultivation of jute relies on minimal pesticides and water, promoting soil health and reducing carbon footprints, whereas polyethylene production involves fossil fuels and energy-intensive processes. Choosing jute over polyethylene supports eco-friendly waste management and reduces plastic pollution in terrestrial and marine ecosystems.

Strength and Durability Comparison

Jute bagging offers superior tensile strength and natural resistance to wear, making it ideal for heavy-duty agricultural and industrial applications. Polyethylene bagging, while water-resistant and flexible, tends to degrade under prolonged UV exposure and mechanical stress, reducing its long-term durability. The biodegradability and robust fiber structure of jute provide enhanced sustainability alongside reliable strength, outperforming polyethylene in strength and durability metrics.

Cost Analysis: Jute Bagging vs Polyethylene Bagging

Jute bagging generally incurs a higher initial cost compared to polyethylene bagging due to raw material and manufacturing expenses, but offers long-term savings through biodegradability and reuse potential. Polyethylene bagging is more cost-effective upfront with lower production costs and greater water resistance, making it ideal for short-term use. Analyzing total cost of ownership, jute bags provide economic advantages in sustainable packaging applications despite higher purchase prices.

Applications in Agriculture and Industry

Jute bagging offers superior breathability and biodegradability, making it ideal for storing agricultural products like potatoes, onions, and coffee beans, where moisture control is critical to prevent spoilage. In contrast, polyethylene bagging provides excellent moisture and chemical resistance, favored in industrial applications requiring durable, water-tight packaging, such as chemical storage and heavy machinery parts. Both materials serve distinct roles: jute supports sustainable agricultural practices, while polyethylene caters to intensive industrial needs with long-term protection.

Moisture Resistance and Breathability

Jute bagging exhibits superior breathability due to its natural fiber structure, allowing moisture to escape and preventing the accumulation of dampness that can lead to mold growth. In contrast, polyethylene bagging offers higher moisture resistance by creating a waterproof barrier, but this lack of ventilation can trap condensation and compromise product quality. Choosing between jute and polyethylene bagging depends on balancing the need for moisture protection with air circulation requirements for specific storage and transportation conditions.

Safety and Health Considerations

Jute bagging offers superior breathability and biodegradability, reducing the risk of mold and bacterial growth compared to polyethylene bagging, which can trap moisture and create unsafe storage conditions. The natural fibers in jute minimize exposure to harmful chemicals, whereas polyethylene bags may off-gas volatile organic compounds (VOCs) harmful to workers' respiratory health. Jute's eco-friendly and non-toxic properties improve workplace safety and reduce environmental hazards linked to plastic waste.

Recycling and End-of-Life Management

Jute bagging offers superior biodegradability and compostability compared to polyethylene, making it a more environmentally sustainable option for recycling and end-of-life management. Polyethylene bags, derived from non-renewable fossil fuels, often accumulate in landfills and oceans due to their low degradability and complex recycling processes. Choosing jute bagging reduces plastic pollution and supports circular economy initiatives through natural fiber decomposition and easier recycling pathways.

Future Trends in Bagging Solutions

Jute bagging is gaining momentum as a sustainable alternative to polyethylene bagging due to its biodegradability and eco-friendly properties, aligning with global trends towards reducing plastic waste. Innovations in jute processing and composite materials are enhancing durability and water resistance, making jute bags more competitive for agricultural and industrial packaging. Future trends indicate a rising demand for biodegradable packaging solutions, driving investment in bio-based jute bagging technologies and hybrid materials combining natural fibers with biodegradable polymers.

Jute Bagging vs Polyethylene Bagging Infographic

materialdif.com

materialdif.com