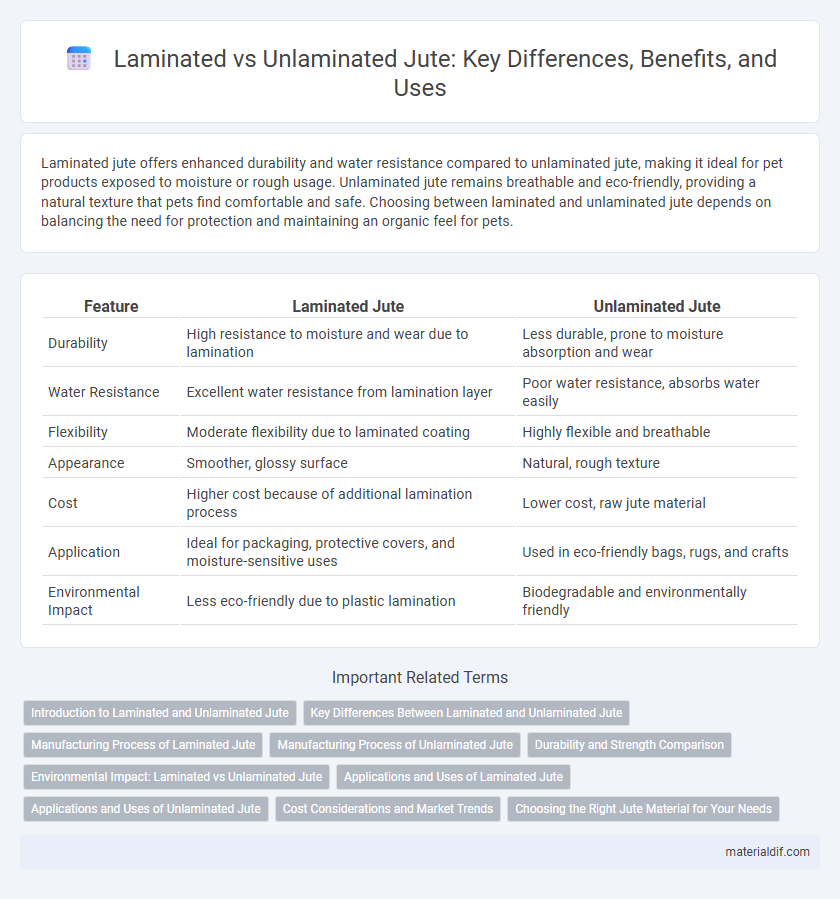

Laminated jute offers enhanced durability and water resistance compared to unlaminated jute, making it ideal for pet products exposed to moisture or rough usage. Unlaminated jute remains breathable and eco-friendly, providing a natural texture that pets find comfortable and safe. Choosing between laminated and unlaminated jute depends on balancing the need for protection and maintaining an organic feel for pets.

Table of Comparison

| Feature | Laminated Jute | Unlaminated Jute |

|---|---|---|

| Durability | High resistance to moisture and wear due to lamination | Less durable, prone to moisture absorption and wear |

| Water Resistance | Excellent water resistance from lamination layer | Poor water resistance, absorbs water easily |

| Flexibility | Moderate flexibility due to laminated coating | Highly flexible and breathable |

| Appearance | Smoother, glossy surface | Natural, rough texture |

| Cost | Higher cost because of additional lamination process | Lower cost, raw jute material |

| Application | Ideal for packaging, protective covers, and moisture-sensitive uses | Used in eco-friendly bags, rugs, and crafts |

| Environmental Impact | Less eco-friendly due to plastic lamination | Biodegradable and environmentally friendly |

Introduction to Laminated and Unlaminated Jute

Laminated jute features a protective coating layer that enhances durability, water resistance, and strength, making it ideal for heavy-duty applications such as packaging, upholstery, and flooring. Unlaminated jute retains its natural texture and breathability, offering eco-friendly benefits and suitability for lighter, decorative, and biodegradable products like bags, curtains, and crafts. The choice between laminated and unlaminated jute depends on specific performance needs, balancing robustness with environmental sustainability.

Key Differences Between Laminated and Unlaminated Jute

Laminated jute features a protective polymer layer that enhances water resistance, durability, and tear strength compared to unlaminated jute, which remains more breathable and environmentally friendly but less resistant to moisture and abrasion. Laminated jute is commonly used in applications requiring extended lifespan and enhanced protection such as packaging, while unlaminated jute suits eco-friendly products like bags and upholstery. The key differences lie in laminated jute's increased weight, stiffness, and synthetic coating versus unlaminated jute's natural texture, flexibility, and biodegradability.

Manufacturing Process of Laminated Jute

The manufacturing process of laminated jute involves coating or bonding multiple layers of jute fabric with a protective polymer film to enhance durability, water resistance, and tensile strength. This lamination typically utilizes materials like polyethylene or polyurethane applied through heat pressing or adhesive lamination techniques, ensuring a strong, flexible composite suitable for packaging and industrial applications. In contrast, unlaminated jute remains in its natural woven form, lacking the enhanced protective properties provided by lamination.

Manufacturing Process of Unlaminated Jute

Unlaminated jute undergoes a traditional manufacturing process involving retting, stripping, and drying to extract natural fibers without any coating or lamination. The fibers are then spun into yarn, preserving their eco-friendly properties and breathability ideal for sustainable products. This process contrasts laminated jute, which incorporates an additional layer for enhanced durability and water resistance.

Durability and Strength Comparison

Laminated jute features a protective synthetic layer that significantly enhances its durability and resistance to moisture, making it ideal for heavy-duty applications and outdoor use. Unlaminated jute, while eco-friendly and biodegradable, tends to have lower tensile strength and is more susceptible to wear, tear, and environmental damage. The lamination process improves the strength of jute fibers by adding a waterproof barrier, extending the lifespan of products in demanding conditions.

Environmental Impact: Laminated vs Unlaminated Jute

Laminated jute involves a plastic or polymer layer that enhances durability but significantly reduces biodegradability, contributing to long-term environmental pollution. Unlaminated jute remains fully biodegradable and compostable, ensuring minimal ecological footprint and promoting sustainable waste management. Preference for unlaminated jute supports eco-friendly practices by preventing microplastic contamination and facilitating soil health through natural decomposition.

Applications and Uses of Laminated Jute

Laminated jute is widely used in packaging, upholstery, and automotive interiors due to its enhanced durability, water resistance, and improved tensile strength compared to unlaminated jute. Its lamination process creates a protective layer that extends the lifespan of products, making it ideal for bags, flooring underlays, and eco-friendly composites. Unlaminated jute, while biodegradable and breathable, is limited to applications like wrapping, sacks, and agricultural uses where moisture resistance is less critical.

Applications and Uses of Unlaminated Jute

Unlaminated jute retains its natural texture and breathability, making it ideal for applications such as eco-friendly packaging, agricultural sacks, and rustic home decor where moisture absorption and biodegradability are essential. Its uncoated surface allows for effective soil erosion control and use in geotextiles, providing reinforcement while permitting water permeability. Industries leverage unlaminated jute in crafting artisan bags, upholstery, and wall coverings that prioritize sustainability and organic appeal over moisture resistance.

Cost Considerations and Market Trends

Laminated jute generally carries a higher production cost due to the added lamination process, which enhances durability and water resistance, appealing to niche markets demanding premium quality. Unlaminated jute remains more cost-effective, widely favored in bulk applications like packaging and agriculture, where price sensitivity dominates purchasing decisions. Market trends indicate growing demand for laminated jute in sustainable fashion and home decor sectors, while unlaminated jute continues to thrive in traditional industrial uses driven by its biodegradability and lower price point.

Choosing the Right Jute Material for Your Needs

Laminated jute offers enhanced durability and water resistance due to its protective coating, making it ideal for outdoor applications and packaging that require moisture protection. Unlaminated jute retains its natural breathability and flexibility, preferred for eco-friendly bags, upholstery, and crafts where a biodegradable option is essential. Selecting between laminated and unlaminated jute depends on balancing the need for durability against environmental impact and specific project requirements.

Laminated Jute vs Unlaminated Jute Infographic

materialdif.com

materialdif.com