Jute yarn spinning involves coarser fibers that require minimal processing compared to the fine, highly processed fibers in cotton yarn spinning. Jute fibers are longer and rougher, making the spinning process more energy-efficient but resulting in less soft yarn. Cotton yarn spinning uses shorter fibers that demand refined carding and combing stages to produce soft, durable yarns suitable for a wide range of textiles.

Table of Comparison

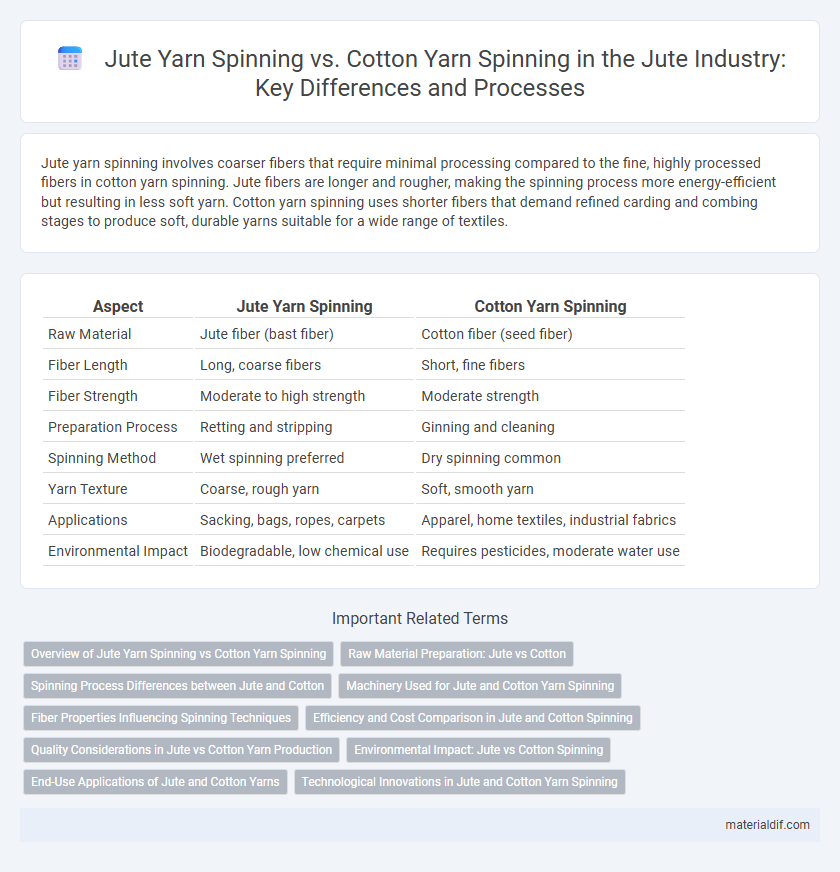

| Aspect | Jute Yarn Spinning | Cotton Yarn Spinning |

|---|---|---|

| Raw Material | Jute fiber (bast fiber) | Cotton fiber (seed fiber) |

| Fiber Length | Long, coarse fibers | Short, fine fibers |

| Fiber Strength | Moderate to high strength | Moderate strength |

| Preparation Process | Retting and stripping | Ginning and cleaning |

| Spinning Method | Wet spinning preferred | Dry spinning common |

| Yarn Texture | Coarse, rough yarn | Soft, smooth yarn |

| Applications | Sacking, bags, ropes, carpets | Apparel, home textiles, industrial fabrics |

| Environmental Impact | Biodegradable, low chemical use | Requires pesticides, moderate water use |

Overview of Jute Yarn Spinning vs Cotton Yarn Spinning

Jute yarn spinning primarily involves coarse fibers obtained from jute plants, requiring a water-based retting process and specialized machinery to handle its long, less flexible fibers, whereas cotton yarn spinning uses short, soft fibers that undergo carding and combing for smoothness. The spinning of jute yarn emphasizes strength and durability, making it ideal for packaging materials, while cotton yarn spinning focuses on softness and elasticity suited for textiles and garments. Differences in fiber length, fiber texture, and processing techniques result in distinct methods tailored to each material's unique properties.

Raw Material Preparation: Jute vs Cotton

Raw material preparation for jute yarn spinning involves retting, stripping, and washing to extract long, strong fibers from the jute stalks, while cotton yarn spinning starts with ginning, cleaning, and carding to separate cotton fibers from seeds and impurities. Jute fibers require careful moisture control and softening during processing due to their coarse nature, contrasting with the finer, more delicate handling of cotton fibers to maintain fiber quality. The physical structure and fiber length differences between jute and cotton dictate distinct raw material preparation techniques critical to efficient yarn production.

Spinning Process Differences between Jute and Cotton

Jute yarn spinning involves a retting process to extract fibers from the jute stalks, while cotton yarn spinning starts with harvesting cotton bolls and ginning to separate fibers from seeds. The jute spinning process uses wet spinning to align and strengthen long, coarse fibers, contrasting with cotton spinning, which employs dry spinning techniques for shorter, finer fibers. Jute fibers require additional softening and washing to reduce brittleness, whereas cotton fibers undergo carding and combing to ensure uniformity and smoothness in the yarn.

Machinery Used for Jute and Cotton Yarn Spinning

Jute yarn spinning employs machines such as the jute breaker, jute carding machine, and jute spinning frame, designed specifically to handle coarse, long fibers and high lignin content, while cotton yarn spinning utilizes carding machines, drawing frames, and ring spinning machines optimized for soft, fine fibers with lower lignin. The production line for jute yarn includes water retting and mechanical extraction processes prior to spinning, whereas cotton spinning focuses mainly on fiber cleaning and uniform alignment stages. Jute spinning machinery is robust to accommodate its fibrous texture, whereas cotton spinning equipment emphasizes precision and speed to produce fine, consistent yarns for textiles.

Fiber Properties Influencing Spinning Techniques

Jute yarn spinning requires coarser, longer fibers with higher tensile strength and lower elasticity compared to cotton, which involves finer, shorter, and more elastic fibers suited for delicate spinning processes. The rough, stiff nature of jute fibers demands specialized processing techniques to prevent breakage, while cotton's soft, flexible fibers enable smoother and higher-speed spinning. Fiber moisture absorption and fiber length uniformity significantly influence the choice of spinning machinery and tension control in both jute and cotton yarn production.

Efficiency and Cost Comparison in Jute and Cotton Spinning

Jute yarn spinning is generally more cost-effective than cotton yarn spinning due to lower raw material costs and less intensive processing requirements. While cotton yarn spinning offers higher efficiency with faster spinning speeds and better machinery automation, jute spinning is favored for its eco-friendly properties and minimal chemical usage. The overall cost-efficiency of jute spinning makes it suitable for bulk, sustainable textile production, whereas cotton spinning remains dominant in high-quality fabric manufacturing requiring fine and uniform yarn.

Quality Considerations in Jute vs Cotton Yarn Production

Jute yarn spinning involves coarser, stronger fibers compared to the finer, more elastic fibers in cotton yarn spinning, impacting durability and texture. The moisture absorption capacity of jute affects its processing speed and quality control, while cotton requires precise handling to maintain fiber integrity and prevent breakage. Quality considerations in jute focus on fiber length and retting process, whereas cotton quality depends more on staple length, fiber strength, and uniformity.

Environmental Impact: Jute vs Cotton Spinning

Jute yarn spinning generates significantly lower environmental impact than cotton yarn spinning due to its minimal water and pesticide requirements during cultivation. The biodegradability and lower processing energy consumption of jute fibers contribute to reduced carbon emissions in jute yarn production. Cotton spinning involves intensive water usage and chemical treatments, leading to higher ecological footprints compared to the more sustainable jute yarn spinning process.

End-Use Applications of Jute and Cotton Yarns

Jute yarn spinning produces coarse, strong fibers primarily used in making sacks, ropes, carpets, and upholstery, catering to industrial and agricultural applications where durability is essential. Cotton yarn spinning yields finer, softer fibers suited for textile products such as clothing, bed linens, and home furnishings, targeting comfort and aesthetics in everyday wear and household items. The end-use applications of jute emphasize eco-friendly, heavy-duty utility goods, while cotton serves the fashion and home textile markets with breathable, lightweight fabrics.

Technological Innovations in Jute and Cotton Yarn Spinning

Technological innovations in jute yarn spinning have focused on enhancing fiber extraction and refining carding machinery to reduce impurities and improve yarn strength, contrasting with cotton yarn spinning, where advancements center around high-speed ring spinning and rotor spinning technologies to increase productivity and uniformity. Jute spinning benefits from bio-mechanical enhancements and machinery tailored to its coarser fibers, while cotton processing leverages automation and precision controls for fine fiber handling and blending. Both sectors integrate digital monitoring systems, yet jute yarn spinning innovations prioritize sustainable processing methods to address environmental impact more directly than traditional cotton spinning technologies.

Jute Yarn Spinning vs Cotton Yarn Spinning Infographic

materialdif.com

materialdif.com